Types of gas boilers

On the market, you can with equal probability find gas boilers of both domestic and foreign production. The cost of both options can vary within a fairly wide range - the final price is influenced by the country of origin, the technical characteristics of a particular model and a set of additional features. The selection of the appropriate option should always be based on these parameters.

One of the classification parameters is the installation method, depending on which there are two main types of gas boilers:

- Floor standing... This category of boilers was originally designed for floor installation. As a rule, floor-standing household gas boilers are rather large, so you have to select a separate place for them. Due to their characteristics, such devices can provide an entire building with heat and hot water. The installation of floor-standing boilers is quite simple, so there are no problems in the process of this work.

- Wall mounted... Such devices have rather compact dimensions, high power and performance indicators. Wall mounted boilers are very popular - they can be found in most private houses. Due to their good performance characteristics, such devices effectively supply the house with heat energy and hot water, and good visual data make it possible to harmoniously integrate a wall-mounted gas boiler into the interior of the room.

In addition to the installation method, gas boilers are also classified by the number of circuits, depending on which two categories of devices are distinguished:

- Single-circuit gas boilers... A distinctive feature of single-circuit boilers is the ability to heat the building and the absence of other possibilities. As the name implies, such devices have one heating circuit designed to heat the coolant and supply it to heating devices.

- Double-circuit gas boilers... This category of devices is a universal solution that allows you to provide a house not only with heat, but also with hot water. Versatility is achieved due to the presence of two independent circuits, one of which is designed to warm up the coolant, which is later transferred to the batteries, and the second - for heating the water used in everyday life.

Single- and double-circuit household gas boilers are quite reliable and efficient, so you need to choose the most suitable type, taking into account individual needs. It is only worth noting that both types of boilers are in good demand and can have very different parameters.

Choosing a floor boiler: how not to be mistaken

Before going to the store, you should carefully analyze the features of the heated object in order to clearly understand the operating conditions of the device. Based on this, the characteristics of the equipment are selected.

Gas unit power

One of the main factors determining the choice of a boiler. Standard recommendations suggest determining the required power of the device from the following ratio: 1 kW of power produced by the unit will be required for 10 square meters of the building.

However, this is a very average figure. It does not take into account the heat loss of the building, the height of the ceilings in the room, the number of doors and windows, their thermal insulation and much more. If possible, a specialist should calculate the required boiler output.

One more point. It is usually recommended to select a boiler with a certain power reserve. This is true, but this stock should not be large.Otherwise, it will lead to rapid wear of the equipment and constant excessive consumption of fuel. For single-circuit boilers, the power reserve should not exceed 15%, for double-circuit boilers 25%.

Specificity of fuel consumption

If possible, it is advisable to choose the most economical boilers. This includes all condensing models. Compared to traditional devices in similar conditions, they consume 15-30% less fuel. The electronic ignition system will also help save money.

Standard piezo ignition requires constant operation of the pilot burner, which leads to excessive gas consumption. This is not necessary for an electronic system. Such boilers are very expensive, but in the process of operation the investments quickly pay off.

Double-circuit boilers are very convenient for small buildings, since they allow you to simultaneously heat the house and provide it with hot water

Optimal number of contours

It makes sense to think about purchasing a double-circuit boiler only if there is a need for hot water supply. In this case, it is worth installing a device with two circuits only in a small or medium-sized building.

For large houses, the installation of double-circuit boilers is impractical, since the power of the device for full-fledged operation is most often not enough. In addition, the security of the system suffers.

Heat exchanger priority material

Copper is not considered in this case. Steel or cast iron only. The first option is chosen if you want to save money. But you need to be prepared for the fact that in a few years you will have to change the heat exchanger. For long-term trouble-free operation of the boiler, a cast iron assembly is chosen.

Construction type and performance

For floor-standing gas boilers, efficiency is considered normal, varying in options from 80 to 98%. Condensing models differ in efficiency ranging from 104 to 116%. The higher this value is, the more efficient the boiler is and the less fuel it uses.

For double-circuit models, the capacity of the DHW system can vary from 2.5 to 17 liters per minute. The performance and power of the unit affect its cost, the higher it is, the higher the price of the device.

Best control system

The most convenient and safe to use are boilers with automatic control. They are able to function autonomously, without constant control of the owner. These are expensive and complex systems.

It is possible to use more budgetary boilers with manual control, but in this case its operation will have to be controlled by turning on / off the device to obtain a comfortable temperature in the room.

An excellent option in the operation of a gas boiler is the presence of a built-in thermostatic sensor. If not, it is recommended to purchase and install a thermostat so as not to waste energy and overload heating equipment.

Floor standing boilers with automatic control are considered to be the most convenient to operate. They do not require constant monitoring, while they work safely and efficiently.

The rules for adjusting the automation unit of gas equipment are given in the article, the contents of which we advise you to familiarize yourself with.

Acceptable design and dimensions

The dimensions of the boiler and its appearance are selected based on the area of the combustion room. Manufacturers offer a large selection of a wide variety of models of various designs and dimensions, which allows you to choose the device that is most suitable for a particular room. It is important to remember that completely free access to the boiler and additional equipment must be ensured.

The best models of gas boilers are presented in an article in which the selection criteria are detailed, all the arguments are given on the basis of which you can make a balanced purchase.

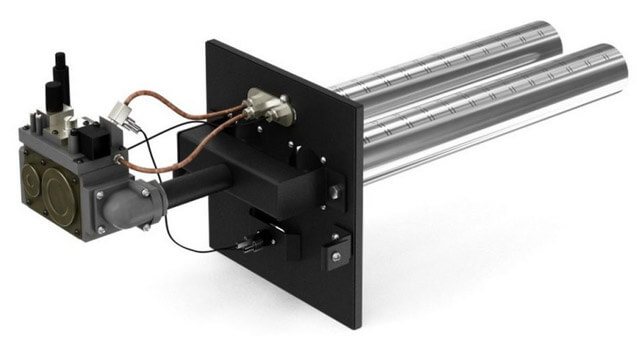

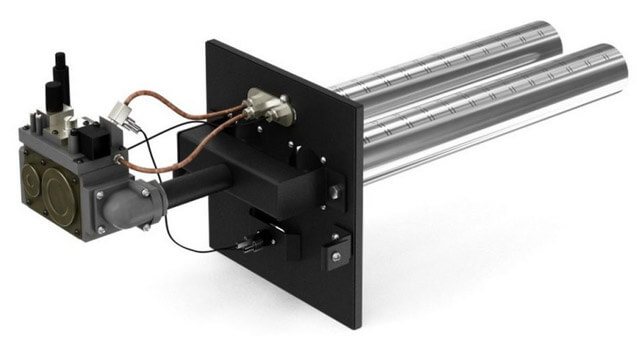

Burners for gas boilers

Gas boilers, regardless of their type, can be equipped with different burner options. The cost of the entire boiler ultimately depends on the quality of the burner and its features. When choosing a boiler, it is imperative to pay attention to the type of burner and its quality. It is better to overpay a little, but so that the burner for the boiler is reliable and durable.

There are two main types of gas burners used in domestic boilers:

- Atmospheric... This category of burners is distinguished by its extreme simplicity of design, and, as a result, very low cost. In addition, it is worth noting the minimum noise level of such devices - during operation, the atmospheric burner is almost inaudible. The main feature of atmospheric-type burners also deserves attention - if necessary, they can be quickly changed with your own hands to transfer the boiler to another fuel.

- Inflatable... Inflatable burners differ from the previous ones primarily in power, which is due to the fact that a certain volume of gas is supplied under pressure. Most often, such burners are used to heat houses with a large area, various industrial buildings, etc.

Heating device power

Wall-hung double-circuit gas boilers

A gas boiler for heating a house in terms of power level can be one-stage or two-stage.

Single-stage devices operate at one constant power level, which is inefficient in terms of gas consumption. After all, the house is heated only 5 months a year, and at the same time, the full power of the operating equipment is not always needed.

Two-stage devices allow:

- regulate the flow of gas, which leads to savings

- reduce the number of switching on and off the boiler, which leads to its long-term operation

- limit the amount of harmful emissions into the air around us

In addition to two power levels, gas equipment is equipped with a smooth switching of the consumed gas, which is called modulation. This function allows better saving of consumed fuel and joint use of a boiler and a boiler of different capacity, installed separately.

It is important to know that gas appliances with a power of more than 30 kW should be located in separate rooms with individual access to the street, chimney and ventilation.

Types of heat exchangers

Another parameter that you definitely need to pay attention to is the material for the manufacture of the heat exchanger. This parameter directly affects the efficiency and durability of a domestic gas boiler.

The following heat exchanger options are available:

- Cast iron... Cast iron is a traditional material that has been used in heat exchangers for quite some time. At one time, cast iron was the only material due to the lack of competition, but today it is not used very often.

- Steel... The heat exchangers made of steel are very robust and reliable. Such devices are easily and safely transported, installed without any problems and work quite efficiently. Black steel is susceptible to corrosion, but during the manufacture of the heat exchanger, the material is coated with chromium, which provides it with reliable protection against moisture and air.

- Aluminum... The key advantage of aluminum heat exchangers is a very high heat transfer, due to which the heating of the coolant increases and the efficiency of the heating system increases. By itself, aluminum is strong enough, therefore, products made from it are easily transported, installed and do not deform under physical influences. Aluminum heat exchangers are considered the best option for gas boilers today.

Functionality and energy efficiency

The main purpose of gas heat generators is space heating.Such a boiler is equipped with a heat exchanger, which gives off heat energy to the heat carrier moving through it. Such boilers are called single-circuit. They are used not only for heating: thanks to an indirect heating boiler, such a system is able to provide hot water to a small private house with one / two water points.

Like ten years ago, double-circuit atmospheric heat generators are very popular among our compatriots, which allow them to efficiently heat private houses and create hot water supply in them. They are compact, efficient enough and relatively inexpensive. The only problem is the allocation of a separate room for the boiler room, equipped with a ventilation and smoke extraction system.

For city dwellers, a double-circuit boiler with a closed combustion chamber (turbocharged) is ideal. Such models are safer, more economical and do not need a stationary chimney.

The regular rise in the price of hydrocarbons pushed manufacturers to create modern economical gas heat generators with an efficiency of more than 100%. How it works? Any super-modern and efficient boiler unit has an efficiency of 95-98%. When fuel is burned, part of the thermal energy is spent on vaporization (there is water in any fuel) and on the combustion process itself. In condensing boilers, the principle of obtaining heat not only from burning fuel, but also receiving additional energy, taking it from flue gases, is implemented. This technology adds an additional 7-11% to the plant's efficiency.

We recommend that you watch the video, which describes the design and principle of operation of condensing gas heating boilers.

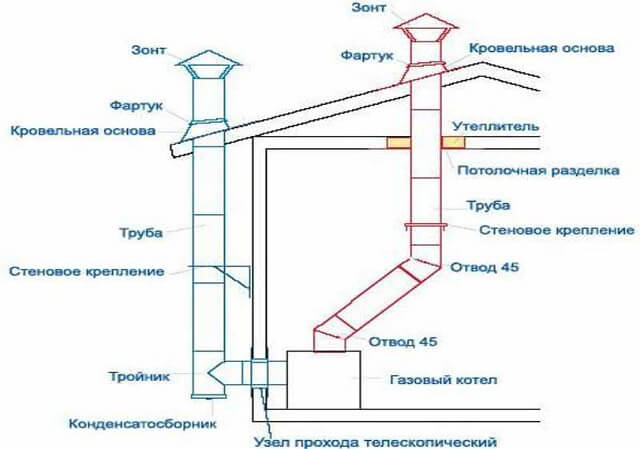

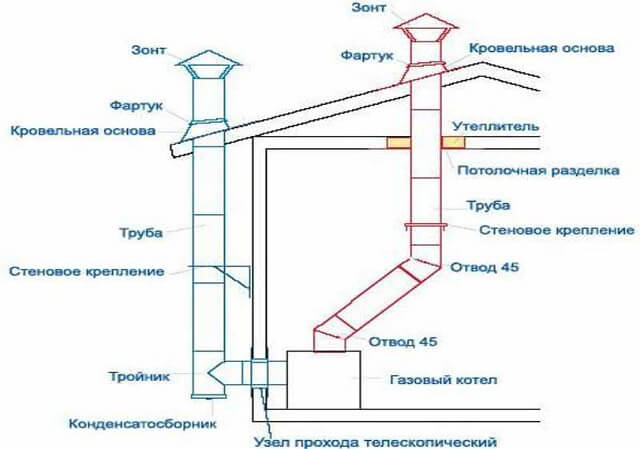

Combustion products removal

The last parameter that you need to pay attention to when choosing a heating gas household boiler is the method of removing combustion products. In floor-standing and wall-mounted boilers, similar designs are used, which differ only in some details.

There are two main solutions for the removal of combustion products:

- Natural draft chimney... In this case, the exhaust gases go into the chimney in a natural way. This technology is based on physical laws - combustion products have a lower specific gravity compared to air, so they are drawn into the atmosphere. To realize natural draft, a vertical chimney must be arranged, which ensures the removal of gases.

- Forced draft chimney... The design in the implementation of such a scheme for the removal of combustion products is distinguished by the presence of ventilation units that ensure the removal of exhaust gases into the atmosphere. This system is much more efficient than the previous analogue, but, unlike it, it is volatile - the fan requires electricity to operate. However, the efficiency and safety of gas equipment operation are worth it.

Which heat exchanger is better - steel or cast iron?

The heat exchanger is the main element in the design of the heating device. And here, when deciding which is better, opinions are divided.

Cast iron structures

Cast iron heat exchanger

Cast iron is more advantageous in terms of its durability compared to its steel counterpart. But it is much heavier and is used mainly in floor-standing boilers. At the same time, the cast iron heat exchanger is less susceptible to corrosion due to the wall thickness.

By the duration of the operation of the cast-iron and steel boiler, the terms are as follows:

- cast iron - 30-40 years

- steel - 15-25 years

The cast iron heat exchanger is more resistant to chemically active substances. This means that it can be used in systems where the coolant is antifreeze or other similar liquids.

Possessing greater inertia due to its mass, cast iron retains the accumulated heat longer, since the design of the heat exchanger of this material is made in the form of several sections.

The disadvantages of a cast iron heat exchanger include:

- Excessive fragility of the material, which requires caution during its transportation and installation - during impacts, microcracks can form in its structure.

- Demanding on the composition of the coolant, since hard water creates a risk of rapid failure.

- The cast iron heat exchanger is sensitive to the temperature difference between the inlet and outlet water. Therefore, it is highly discouraged to supply too cold water, and in order to avoid such a situation, a unit for regulating the temperature of the coolant is arranged at the inlet.

- There is a risk of destruction of cast iron with constant overheating, therefore, constant monitoring of the temperature of the coolant is required.

Important! Despite the fact that boilers with a cast iron heat exchanger are more often used where firewood acts as a heat source, they are easily converted to natural or liquefied gas by replacing the burner.

Steel heat exchangers

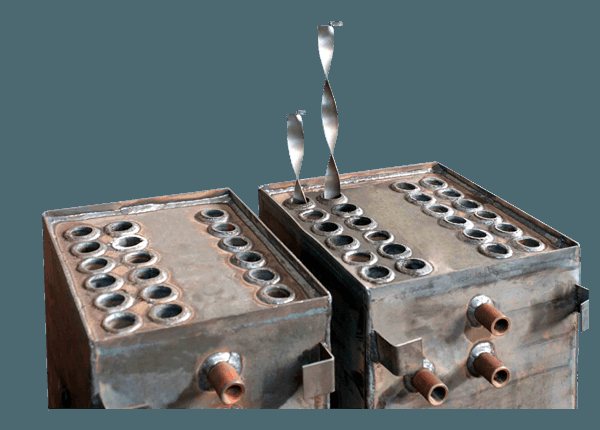

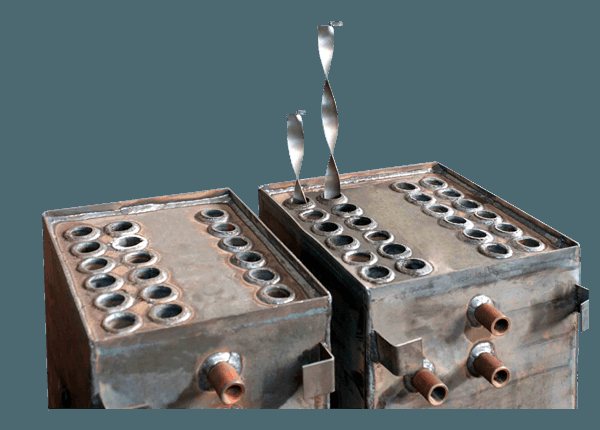

Tubular heat exchanger

Steel structures are lighter in weight and have a more attractive appearance, therefore they fit better into the interior of the room.

Steel, unlike cast iron, is a more ductile material that is not afraid of mechanical stress. Its advantages are in the following characteristics:

- resistance to temperature drops in the coolant

- transportation and installation are straightforward

The disadvantage of steel heat exchangers is the possibility of corrosion. However, this disadvantage is eliminated by correct installation and operation. The main thing is to prevent the temperature of the coolant from dropping below the "dew point", which should be taken care of by the automatic boiler control system.

Copper devices

Gas devices have appeared on the market, where the heat exchanger is made of copper. Naturally, the cost of such units is much higher than all known ones. However, it is compensated by the mass of advantages of such a device:

- Due to the properties of copper, the walls are heated evenly without local overheating of the coolant.

- Minimal sludge and scale inside the copper heat exchanger.

- Due to the low specific gravity of copper, both the heat exchanger and the boiler itself have a low weight.

- Copper is resistant to corrosion.

- The coolant in such devices moves at a higher speed, which does not allow the formation of scale on the walls.

- High efficiency.

- It turns out that such heat exchangers, apart from the high price, have practically no drawbacks.

The advantages of household gas boilers

Installing a gas boiler is one of the simplest, most convenient and inexpensive solutions to heat a house. In order for the system to be extremely versatile and efficient, it is worth choosing a double-circuit natural gas heating boiler, which can not only heat the house, but also provide its residents with hot water supply.

Regardless of the individual characteristics and equipment, all household gas boilers have the following number of advantages:

- Ease of operation... When using main gas, the system can work independently - constantly monitoring the fuel supply, the combustion process and other operational processes are not required. Some nuances arise only when using liquefied bottled gas.

- Profitability... Gas is still the cheapest fuel - it outperforms any liquid or solid fuel in terms of price. In addition, gas boilers consume a minimum of fuel, which indicates the high efficiency of such devices. Even with the constant increase in energy costs, gas heating is still the most profitable option.

- High efficiency... Gas, despite its low cost, is one of the most heat-consuming energy resources, which, in addition, is suitable for heating any premises.Provided that the boiler is correctly selected, the whole house will be well warmed up and provided with hot water, and the resource costs will be minimal.

- Equipment availability... In the modern market of heating equipment, gas boilers are presented in a large assortment, so it will not be difficult to choose the best option for specific operating conditions. Also, one cannot fail to note the widest range of prices, which allows you to find a boiler that can fit into any budget.

How to choose?

To choose the best gas heating unit, you need not only to study the characteristics of the model, but also to study the reviews of consumers who are already using the equipment. Traditionally, the popularity rating of household heating units is headed by German-made models. The most enthusiastic reviews of consumers have boilers of the brands "Buderus", "Bosch", "Valiant".

In addition to models of German production, the rating of popular models includes Italian models of boilers. The best reviews about the brands "Ariston", "Beretta", "Baksi". However, recently, due to the change in the exchange rate of the national currency, models of domestic and Asian production have entered the rating of the most popular brands.

The best reviews are left on South Korean-made models. The rating of the most bought models includes the KITURAMI and NAVIEN models. Both options have excellent performance characteristics, and the NAVIEN boiler is also relatively inexpensive.

Modern gas boilers are compact installations in which the main processes take place automatically. When choosing models, it is worth not only to get acquainted with the description and characteristics, but also to read the reviews of consumers who already use the equipment and know about its weak and strong points.

Installation of units

There are no special difficulties in the technology of installing gas boilers, and most of the stages of this work can be carried out independently. To better understand how to install a gas boiler, it is worth reading the corresponding article, which will describe all the smallest nuances and details.

In short, the installation of boiler equipment is always preceded by a number of preparatory work. First of all, you need to do the design - and this is the calculation of the heating system as a whole, and the determination of the required boiler power, and the selection of a place for its installation, and a number of other issues. The installation of equipment is in a sense simpler than all these operations - usually the installation instructions are attached to the boiler, and you can always follow its instructions.

However, despite the possibility of self-assembly of gas boilers, it is still best to entrust this work to professionals who have the appropriate qualifications, the necessary experience and the required tools. In order to put gas equipment into operation, it will be necessary in any case to invite specialists from the gas service - only they can confirm the correctness of the installation and issue permits. The ideal solution would be to invite licensed specialists who can both install equipment and put it into operation - this is much more convenient and simpler.

Coaxial chimney

For forced air supply and removal of combustion products from a double-circuit boiler with an inflatable burner, a coaxial chimney is used. In the usual sense, it is a structure that is a "pipe in a pipe". The first circuit (inner pipe) is responsible for the removal of combustion products. The second circuit (outer pipe) is responsible for the flow of air into the gas burner device. Air supply and exhaust gases removal from the boiler plant is carried out by a turbine (built-in fan).

Advice: To ensure efficient draft and uniform combustion of gas - modern double-circuit heat generators with a closed-type combustion chamber are equipped with coaxial chimney systems with a length not exceeding 2 meters.

Repair and service

Despite the high indicators of reliability and durability, gas boilers still need to be regularly serviced, and sometimes even repaired. The main rule of repair is as follows - since gas equipment is dangerous, in no case should you try to repair it yourself. In addition to the danger of gas leakage, there are more trivial, but unpleasant moments - for example, you can accidentally make a mistake during repairs and provoke a number of additional problems.

If problems arise in the operation of gas heating equipment, it is best to immediately contact the professionals - the domestic market does not lack good specialists who can deal with any problems. Experienced professionals will fix the problem as soon as possible and fairly cheaply.

So that when repairing a gas boiler there are no additional problems, you need to think carefully about its location in advance. One of the conditions for the competent selection of a place for the boiler is the possibility of free access to all its elements. Only if this condition is met, repair work can be carried out quickly and safely.

For work on regular maintenance and monitoring of equipment operation, this requirement is also relevant - if it is not even possible to approach the boiler normally, then the place for it is not chosen correctly. This moment must be thought out in advance and correctly installed the boiler, bringing it to all the necessary communications.

Management and security

Heating units are equipped with automation systems that ensure safe operation, as well as adjust the boiler to operate in the required temperature mode.

The most modern models are equipped with microprocessors that allow you to configure the equipment so that its further operation will be automatically controlled. There are two options for automation:

- volatile;

- non-volatile.

Non-volatile systems are very easy to operate and fairly inexpensive. They allow you to adjust the operation of the equipment, but fine tuning of the operation is impossible. The system includes:

- thermocouple;

- mechanical temperature sensors;

- flame sensor;

- traction sensor.

Volatile systems allow you to configure equipment not only for standard, but also for individual operating modes. A programmer can be included in the automation system, the task of which is to control the air temperature in the premises and regulate the operation of the boiler.

The volatile control system has the function of diagnosing the equipment and can automatically adjust the operation of the unit in the event of minor malfunctions. If a serious problem arises that cannot be easily adjusted, the system will automatically shut down the boiler.

And after the owners manage to adjust and fix the problem, an automatic start will occur. Using the automatic control system, it is possible to adjust the operation of the heating system so that the gas consumption is minimal.

For example, you can adjust the operation of the unit so that it works in an economical mode during the absence of people in the house, and by the time the household arrives, it warms up the coolant to the specified temperatures. In modern programmers, it is possible to adjust various operating modes, both for a day and for a week.