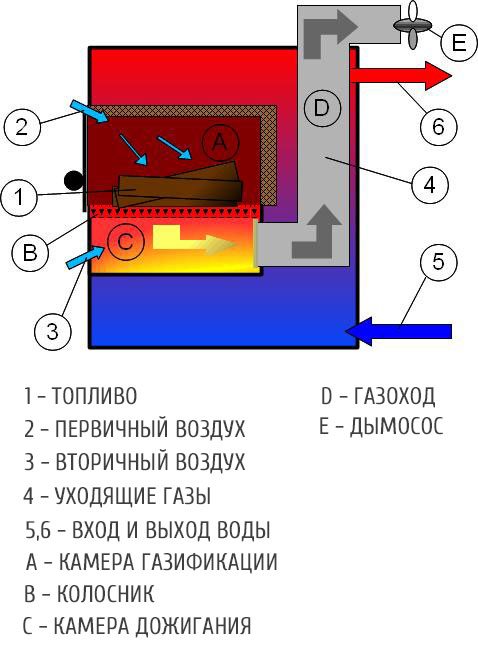

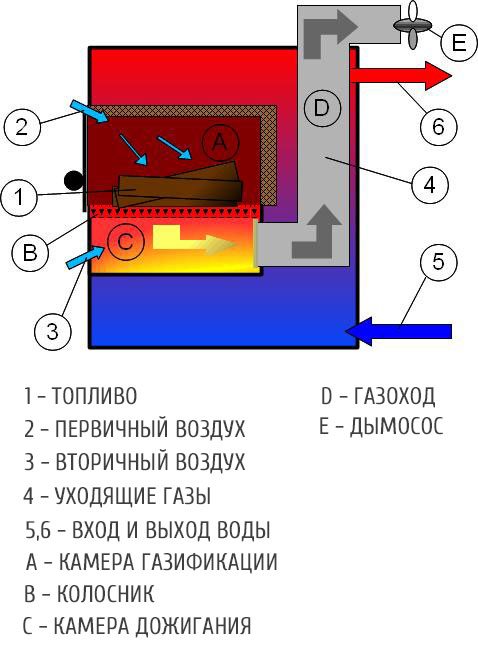

The gas generator furnace is a separate direction in the heating equipment industry. The principle of its operation is as follows: solid fuel burns with a small amount of oxygen, under the influence of low temperature values, pyrolysis gas is produced. This substance mainly consists of methane and carbon monoxide, has a high heat transfer coefficient, which contributes to a manifold increase in the efficiency of such equipment. Fuel in this design burns out almost completely. Heat is transferred through heat exchangers to the liquid in the system.

Various types of gas generator furnaces are offered by many manufacturers of heating equipment. You can also make them yourself.

Features of the device

Such heating devices have two combustion chambers. In the first, the decomposition of solid propellant combustible material occurs. In the second, combustion of the obtained pyrolysis gas (it can be located in relation to the gasification compartment from the bottom, top or side).

A classic gas generator furnace consists of the following elements:

- body (all structural elements are installed in it);

- filling hopper (solid fuel is placed there - firewood or waste from the wood industry);

- afterburner chamber (combustion of pyrolysis gas takes place in it);

- grate grate (it serves to hold solid fuel material);

- doors (with their help firewood is loaded into the equipment and the residues of combustion products are removed);

- air dampers (thanks to them, you can control the supply of oxygen to the working area of the device).

Depending on the type of furnace, its features, the gas generator either heats the jacket of the coolant, or gives off thermal energy to the environment, or combines both of these functions.

Benefits

Gas generator heating devices have a lot of advantages, which led to their widespread use for heating country houses, cottages, outbuildings. Their efficiency is many times higher than the efficiency of traditional heating equipment. In furnaces of this type, you can regulate the temperature of the coolant, control their operation. In this case, the oxygen supply to the furnace is simply increased or decreased.

Such devices can be heated not only with firewood and wood processing waste, but also with coal, peat and, most surprisingly, linoleum.

The most common type of wood-fired gasifier is the pyrolysis oven. Gas is not taken from it, but completely burnt, resulting in the formation of thermal energy.

Principle of operation

So, in order for the wood in the firebox to be able to release the required amount of combustible gas, it is necessary that they burn with a small supply of oxygen. In fact, the fuel should not burn, but smolder. But at the same time, the temperature inside the chamber should be rather big, not less than + 1100 ° С. This is one of the main conditions.

It is very difficult to work with gases of this temperature, because their quality is low enough to be used for its intended purpose. It's just that the efficiency from their combustion will not be very high, so flue gases are usually cleaned. But before that, they need to be cooled a little.

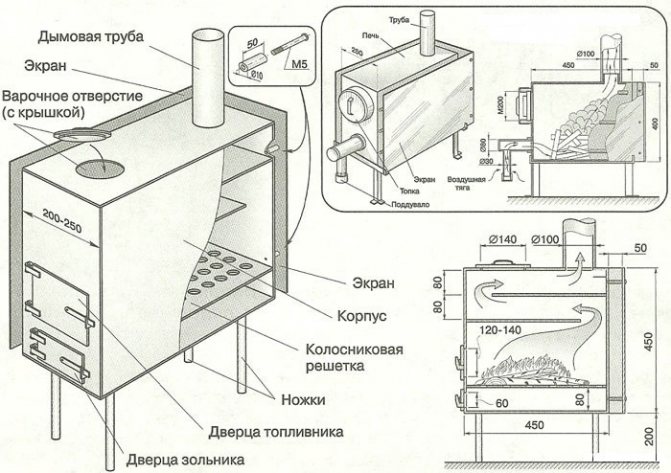

Horizontal model of a gas generator

Gas cleaning is carried out on special filters, where they are cleaned of ash, suspended particles, acids (formic and acetic) and other impurities. Then they enter the mixing tank, where the gases are mixed with fresh air. And now the ready-made air-gas mixture can be used for its intended purpose.This is the principle of the wood-fired gas generator. The process is not the easiest, therefore, the device of this unit is not simple. Although many home craftsmen make them with their own hands.

By the way, solid fuel pyrolysis boilers are one of the varieties of a gas generator. True, they lack the stages of cooling the flue gases and their cleaning. Combustible material immediately from the wood combustion chamber enters the second furnace, where the gases are enriched with oxygen and burned. Gas is not used for other purposes.

Stove-heater "Miracle"

Such a heating device for a long time heats rooms of any purpose with high quality, while little fuel is spent.

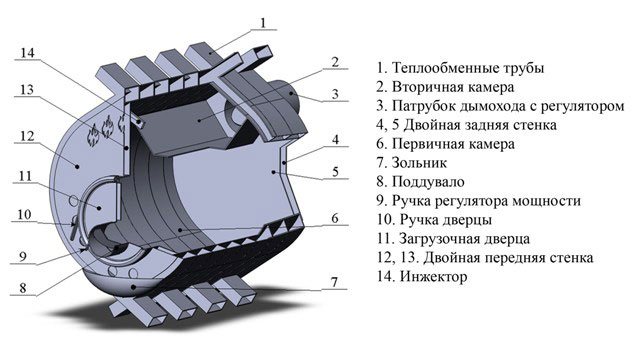

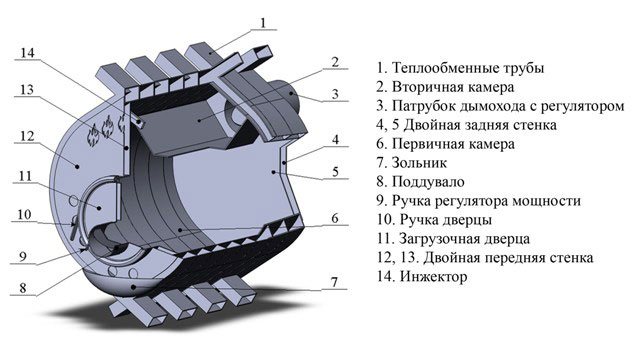

Device

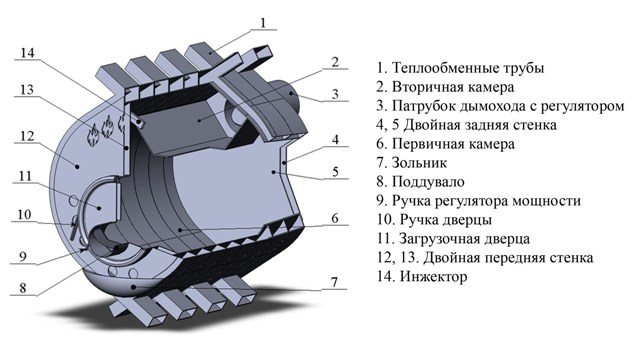

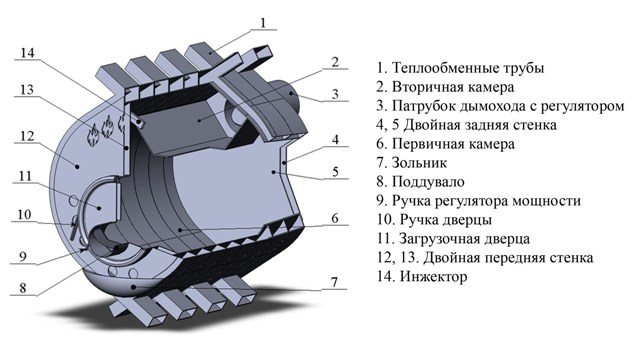

This appliance is an all-welded steel structure. The transfer sheet divides the combustion chamber into two compartments. In the upper one there are nozzles and an injector. At the bottom - smoldering fuel.

The heater is covered with a special steel casing: it reduces the heating temperature of the walls of the device and allows the heat to come out evenly. Thanks to this element, it is impossible to burn yourself on the stove.

Principle of operation

The gas generation process is the smoldering of fuel with a minimum supply of oxygen. Reburning of gas takes place with the help of special nozzles.

Such a device can be heated with wood, garbage, dry manure, peat. One insert of fuel material provides the structure with continuous operation for 6-8 hours.

Application area

The “Miracle” heater-heater can be used to heat summer cottages, large cottages, industrial buildings, outbuildings, garages, greenhouses.

Dignity

A similar heating device starts heating immediately after kindling. Heat will come to the house in about 20-30 minutes. In addition, its advantages include independence from gas, oil, electricity, uniform heating of the entire room, work with any type of fuel (except coal), high efficiency.

The Chudo stove is an economical and easy-to-use device that does not require special maintenance and care. The combustion process can be controlled. Installation of such equipment is inexpensive. It can be used to cook food and heat water.

Hob models

Despite several limitations, which, unfortunately, accompany the operation of gas generating furnaces, their design allows the presence of a hob... Such units can work for cooking and in the mode of intensive heating of the room, as well as in the mode of prolonged smoldering.

To illustrate the effectiveness of such work, we can cite the averaged data of modern modifications, which are able to provide boiling 6 liters of water in just 30 minutes... There are heating and cooking ovens with long burning with different areas for use in culinary needs, but in all cases, a mandatory requirement is ensuring the flatness of the cooking panel... During installation, this condition can be met using a level gauge.

Back to content

Gas generator boiler Blagodarov

During the operation of the Blagodarov boiler, all substances that are produced as a result of combustion are burned.

The design of such equipment consists of 3 parts. These are combustion and gasification chambers and a bunker for burning fuel combustion elements. The fuel material burns in the 1st of 2 chambers, in the 3rd it becomes gas.

The undoubted advantage of this heating equipment is the long burning of fuel (the device surpasses other heating boilers in this indicator) and good heat transfer. It is independent of electricity, it always delivers the power that is required.

In the process of burning firewood and wood processing waste, the grate, which covers the bottom of the fuel chamber, contributes to the formation of a high level of heat under natural draft conditions. At the Blagodarov boiler, you can expand the volume of the fuel bunker, while the efficiency of the device will not suffer. The rails installed in the combustion chamber are a good heat accumulator.

Coal, sawdust, peat can be used as fuel. In winter, the fuel chamber can be regularly replenished to maintain optimal temperature conditions in the heated room.

The main stages of the production of a gas generator furnace

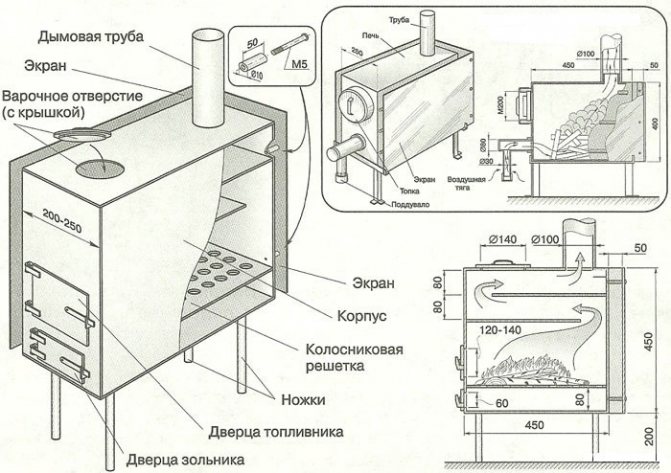

A do-it-yourself gas generator furnace has one extremely important advantage: it will cost much less than most models on the market today. The main distinguishing feature of such a device is that it has two combustion chambers at once. Step one

Step one

First of all, it is necessary to weld a two-chamber metal boiler body, which will have a rectangular shape. What is needed for this? There are two possibilities. In the first one you will need two sheets of metal, and in the second one - an ordinary old iron barrel. In principle, any of them will suit us.

Step two

The main purpose of the lower chamber is to fill the unit with fuel: it is in this place that the formation of pyrolysis starts. In some cases, this area of the furnace is also called the gasification chamber. Firewood, which will be used as fuel in our country, will not burn here - it will only smolder due to the lack (more precisely, a small amount) of oxygen. A large amount of gas formed during the smoldering process enters the upper compartment of the furnace. It is also burned out there.

Step three

This is where the previously stored steel pipe comes in handy. We need to weld it into the body of the device. The only purpose of such a steel pipe is the ability to adjust and control the process of outflow or air flow.

Step four

Next, we take the grate, which we also prepared in advance, and separate the lower and upper chambers with it. It should be understood that the blower is absent as such in gas generating furnaces. And in order to regulate the air flow at the outlet or at the inlet, we install special gasifiers and power regulators.

Step five

We take the heat exchanger and equip it on the furnace body. Its lower tubes are designed so that cold air enters the body, and heated air masses leave through the upper ones.

It should also be noted that the temperature can be regulated by an automatic system. In addition, the finished furnace structure must be coated with special compounds for metal surfaces.

The main advantages of gas generating furnaces

This unit, which has two fireboxes at the same time, has many advantages when compared with conventional devices.

- Gas generating furnaces are produced in five different modifications, which, in turn, are designed to heat rooms with different areas - from hundreds to thousands of square meters.

Fuel is consumed in significantly smaller quantities. One load of firewood will last for about fifteen to eighteen hours. Gas is not needed at all. If desired, you can equip a model that does not need electricity. The temperature formed after the combustion of the gas can be several times higher than the temperature during the combustion of wood. You can use a variety of wood waste as fuel. The combustion of gas can be very easily controlled, its intensity can be regulated.

In most cases, gas generating furnaces are used to heat country houses, garages, various greenhouses, and so on.High-quality models can be equipped for home heating - this will create maximum comfort without the use of any gas cylinders.

Precautions

It is impossible to convert an ordinary furnace into a gas generator. Such manipulations will only lead to smoke pollution of the building. To fully use the gas generator device, it is necessary to take into account its disadvantages.

Cold gas is produced at the outlet of such equipment. Condensation will form if the chimney is not properly insulated. Moisture will drain back into the appliance. Therefore, experts recommend using insulated sandwich structures. They consist of 2 pipes nested into each other, between which the insulation is located.

In order for the gas generator to work as efficiently as possible, an economizer (accessory) must be installed.

How to do it yourself

A homemade gas generator furnace is usually made from affordable materials.

- a thick sheet of metal or iron pipe (you can use a barrel);

- steel corners (5 × 5);

- hinges, door latches;

- chimney pipe;

- reinforcement rods.

The number of materials and various additional elements depends on the size of the room and the tasks assigned to the heating equipment.

The oven has two compartments. The afterburner will be a special labyrinth located at the top of the device. It is made from metal plates, placing them parallel to each other.

Frame

It is made in a rectangular shape, while several metal sheets are welded together. You can use a ready-made barrel or a piece of thick-walled pipe.

Preparation of work items

First, you need to mark and then cut out the details of the future stove: sides, top, panel for the grate, plates for the gas labyrinth (3 pcs.). The edges of such elements must be cleaned with a grinder.

Holes

A round hole is cut in the upper element of the furnace, the chimney will be connected there. In the front wall of the case, hatches are made in the form of rectangles (for firewood and a blower).

Metal pieces that serve as doors are ground and hinges are attached to them. The edges of such structures must be scalded to ensure a snug fit.

Gas labyrinth plates

A plate is installed 10 cm from the top of the facade, perpendicular to it. It should be 7 cm shorter than the length of the entire heating device. Two more plates of the same size are attached to it at the back. The distance from the top is 15 cm. After the complete assembly of the furnace, this structure will become a gas labyrinth that slows down the movement of gas.

Installation of grates

Corners (2 pcs.) Must be welded to the sides of the body at the same height. A grate will be installed on them. It is made from reinforcement rods or from a metal sheet with a large number of slots.

Final assembly

All parts are connected with a corner by welding. The edges are cleaned with a grinder and painted with a refractory compound.

A similar homemade stove can heat small utility rooms. After assembly, it must be tested. If everything is done correctly, the device will start heating the room quickly enough (within 30 minutes).

For those who like to take water procedures in cold season unwittingly, you have to choose reservoirs with cool or completely icy water.

But not everyone can withstand swimming in an ice hole or an unheated font with a temperature 12-15 degrees.

Therefore, the task arises to heat the water. Of course, it will not be possible to heat an entire lake or river. But bath tub or small pool it will not be difficult to heat up.

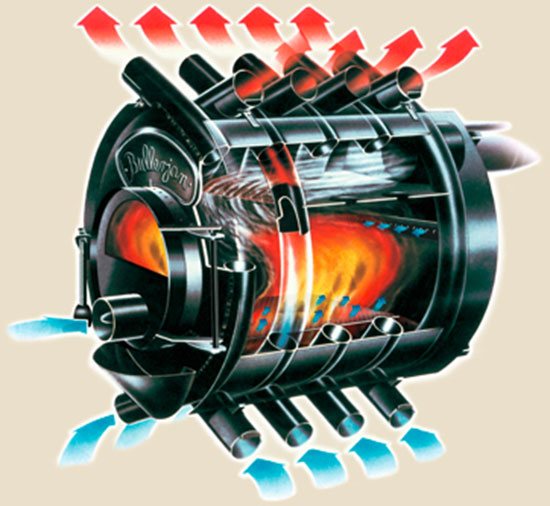

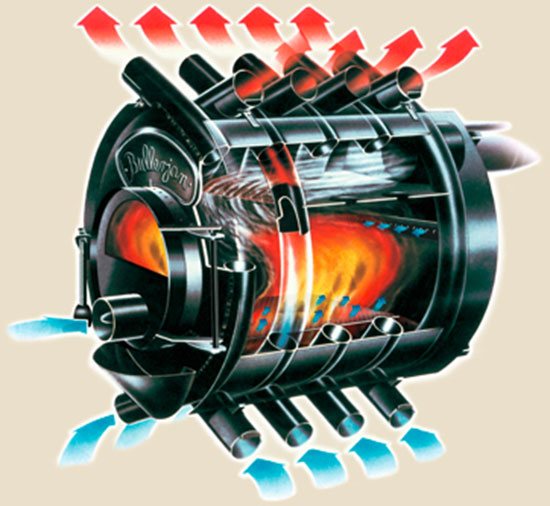

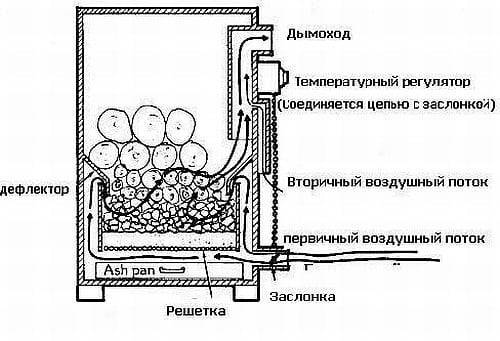

How does the Breneran heating stove work?

- The stove operates in two modes: normal combustion and gas generation or pyrolysis.When a certain temperature is reached, any solid fuel begins to emit a large amount of carbon dioxide. There are two combustion chambers in the design of the furnace. The first is intended for burning wood, the second for afterburning the gas released during the pyrolysis process. As a result, the efficiency of the boiler is increased compared to conventional wood-burning stoves.

- Heating is carried out by air convection. Air masses are constantly circulating in the room. Cold air goes down, and heated air goes up. Breneran metal gas generating furnaces use the principle of air heating of the room. Convection pipes are installed in the design of the equipment. Two-thirds of the channels are immersed in the combustion chamber, which explains the high heat transfer of the structure. Heat begins to flow into the room immediately after kindling. The throughput of convection oven pipes is not less than 4.5 m³ / min.

How to heat up a lot of pool water

In practice, the water in the pool is heated by different methods:

- Via flowingmethod. To heat a large amount of water, its circulation is organized through a heating device. The liquid is taken from the bottom of the pool, filtered and passed through the heater. Warm water under pressure is injected down the pool from the opposite side of the intake.

Electricity, solar energy, burning gas, oil products and wood stoves help to heat the pool in different cases.

Wood burning stove

Solid fuel stoves can handle any amount of heated pool water and are easy to operate and economical.

You can choose the right stove for heating the pool by defining the task that the equipment faces:

- Heating year-round pools with large volume of watermaintaining a constant temperature. To solve this problem, massive brick ovens with a heat exchanger, long-burning boilers of the type "Stropuva", pyrolysis boilers with a shaft structure.

The advantages of such ovens are the possibility maintain the same temperature for a long time in the heat exchanger and regulate the heating rate, long battery life without loads, the ability to heat the pool using indirect heating. The downside is the relative high cost of equipment, complex plumbing.

- Rapid heating seasonal indoor pool and maintaining the required temperature. The main requirement for equipment is high power. It can be calculated knowing the volume of the pool, the difference in water temperatures, and heat loss. To heat up 1 liter of water one degree for 1 hour you need 0.001 kW... Heat 1 thousand liters in 1 hour will require power in 1 kW.

Given the heat loss, you need to multiply this indicator by 1.2-1.3. Thus, the boiler by 25 kW will heat up 1 a cube of water by 1 degree in 15-20 minutes. The water heater must be installed permanently, it is better to use a flow heating scheme.

- Rapid heating small street pool at low ambient temperatures. The main requirement for the boiler for this operating mode is high power and mobility... Light weight and compactness of the oven will be a nice addition.

Output

As a heating system for a home, this option can only be suitable if you adhere to several important safety rules. Such stoves are a good, compact and economical option for installation in premises where people temporarily stay, where the heating takes place intensively and only for a few hours.

Furnaces with a gas generator are widely available on the market, so you can find both domestic and industrial heating solutions. When choosing, it is worth focusing on the required power, operating efficiency, the method of removing the chimney, the material of production, the purpose and thickness of the material from which the structure is made.

When purchasing, you can additionally ask about the availability of detailed instructions for assembly. They must be attached to each furnace, and it is on them that the installation of the structure must be carried out so that there are no difficulties with further operation.

Optimal choice of material for the heater

To choose the right material for your pool heater, you need to consider the following factors:

Opportunity transportation... Due to its high weight, a brick device is best positioned permanently, on a good foundation.

If the pool is collapsible and mounted in different places, then it is better to use a metal structure.

- Availability free space. Metal boilers take up less space than brick ones; a brick structure will need to be protected from the effects of atmospheric precipitation: build a roof or assemble a stove in a building.

- Cost and availability materials.

- Opportunity to attract a qualified welder or bricklayer.

The brick boiler is durable and looks good. A brick oven can also perform a number of other functions: heat the room, cook food... With the skills, such a device can be made independently, which will significantly reduce the cost of the entire heating system.

Homemade metal construction is chosen if the budget is limited.

Boiler diagram

Various types of structures are used to heat the pool water. Appliances consist of a firebox, heat exchanger, housing and chimney.

Metallic units are mobile, have high efficiency, do not require a solid foundation.

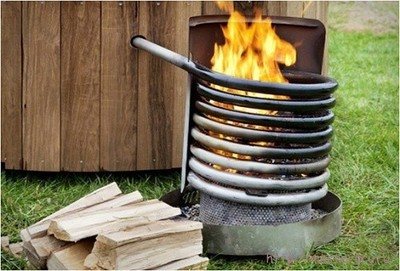

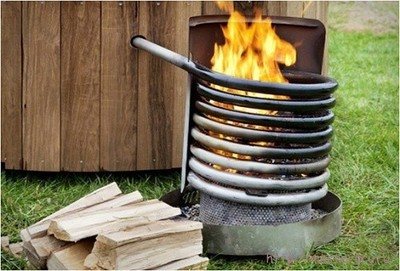

The simplest home-made device for heating water in the pool is a metal cylinder, inside which is laid along the walls heat exchanger: stainless steel coil... Firewood is burned inside, water is supplied by a pump or flows itself into the pool located nearby.

Photo 1. For the manufacture of a pool heater, a similar coil is needed: this is a heat exchanger through which the coolant will circulate.

Metal potbelly stove with built-in heat exchanger harder to do, but more efficient. The firebox is located under the heat exchanger, which can be a mesh of welded pipes, a coil, edges of cast-iron batteries, car radiators with rarefied plates. Hot gases passing through the heat exchanger heat the circulating liquid.

In boilers based on a long burning stove Buleryan all fuel goes to heating the passing water. Home craftsmen have long learned how to make such devices from shaped pipes and sheet metal.

The issue of heating country houses and garages, industrial and residential premises is always relevant. Many are interested in how the heater heater works, whether it can cope with the task at hand. This is a fairly simple and small device that can heat a room in a few minutes.

The stove takes up little space, is easy to operate and maintain, and the reasonable price contributes to the growth of its popularity among owners of summer cottages and garages. Having purchased a set of drawings and having the skills to carry out welding work, this device can be made by hand.

Assembly tips and tricks

Do not forget about the importance of proper installation and configuration of the structure. Follow these tips: (See

(See also: Solid Fuel Stoves)

- When installing a device such as a gas-fired heating stove, in particular when installing its chimney, assemble the pipes in the opposite order to the movement of gases. This will prevent the resin deposits from getting to the floor - they will burn inside the oven, rising to a higher level.

When placing the structure, do not forget that the oven can be heated to very high temperatures - the space around it must be free so as not to provoke a fire.

When assembling the chimney, try to make it easily disassembled, otherwise, if resin accumulates in it, the device will fail, and you will be tormented by disassembling a complex chimney.

(See also: Sitemap)

Try experimentally to determine the required combustion temperature for your firewood. The fact is that the requirements for the dryness of firewood, which are imposed by long-burning gas-generating furnaces, are not always met and not by all owners. Therefore, you need to determine at what temperature exactly the combustion of all resin clots formed during the combustion of your firewood occurs.

Try to choose the operating mode of the device "for yourself" - so that it provides enough heat, and its operation time is long, and at the same time there is a minimum of clogging of the chimney.

Types of heaters

A heater, or an air heater, is device designed to heat a large room with one heat source... The air heated by the oven is distributed through specially arranged channels throughout the room, heating it.

The principle of operation of the oven is based on natural circulation of heated air - convection.

Furnaces are available with solid or liquid fuels. Some craftsmen make their own combined stoves using solid and liquid fuels.

The principle of operation of such boilers is based on the pyrolysis of organic fuel. In the process of fuel combustion with a lack of oxygen (smoldering), flammable gases are formed, which burn out in a separate chamber. It is this process that makes it possible to increase the furnace efficiency up to 85-90%. Another name for such furnaces is gas generating.

The air heater, installed on the walls of the air heater and divided by metal guides into channels, provides convection. The air, moving inside the guide channels, heats up, thereby cooling the surface of the walls, preventing them from overheating.

Wood-fired heater

A striking representative of such devices is the “Miracle” stove-heater (KN-50) in the photo below. It is a horizontal type all-metal welded structure. The cross-section of the body is represented by 2 trapezoids connected by bases. Air heaters are welded to the sides of the furnace, which are at the same time protective screens. The top of the oven is flat and narrower than the bottom. It has a chimney pipe with a built-in gasifier-regulator, made in the form of a damper, with manual lever control. The stove is installed on legs, which ensures the required clearance of 150 mm. The chimney is made by hand from a pipe with a diameter of 110 mm.

Now this stove can be purchased on the market in the region of 5-6 thousand rubles, an economical option.

The combustion chamber is divided by a horizontal partition. A round door with a lock is installed on the front wall. A power regulator with a damper is also mounted there. The stove does not have a grate and a blower, in contrast to the Buleryan Breneran convection stove in the first picture. The supply and regulation of the supplied air volume is carried out by the power regulator. The fuel is dry chipped firewood, wood processing waste, peat. In rare cases, brown coal is used.

After firing up the device, the main fuel is put into the furnace, filling the entire volume. Later, when the wood is burning, the power regulator and the gasifier are covered by about half. Fuel combustion turns into smoldering, as a result of which flammable gases are formed (pyrolysis). More details can be seen in the photo below.

The afterburning of these gases occurs in the upper chamber of the furnace due to the formation of vortex flows. As a result of such combustion, a large amount of heat is released, which goes to heating the room.

The burning time of one bookmark of firewood is 4-8 hours and depends on the size of the firebox.To increase the thermal power, the size of the heater is increased.

For example, a heater-heater KN-50 is capable of heating a room with a volume of 50 m³, and KN-1000 - 1000 m³. In this case, the length of the firebox increases from 500 mm to 1150 mm.

With such a heating device, you can quickly heat your country house or garage, without spending time on laying firewood and controlling combustion. It is forbidden to put firewood until it has completely burned out due to the possibility of the release of combustion products into the premises. The end time of combustion is determined by the wall temperature. The regulators must be fully opened before adding a new portion of fuel.

Fuel selection and installation features

A long-burning stove can work from oil, electricity or gas, allowing you to evenly heat the room. And also most types of solid fuels can be used, be it waste paper, firewood, sawdust or tree bark. Fuel loading into the stove can be manual or automatic, depending on the model and type of fuel. The heating time of such a furnace on one tab is different, depending on its size and technical characteristics, on average, it is 8-10 hours. Coal and coke are not suitable as fuels for steel furnaces. During their combustion, the temperature of the equipment becomes critical and can render the furnace unusable. With proper operation, the service life of the device will be as long as possible - from 3 years or more.

This device has proven itself to be an excellent heating device, but with a water circuit, its value increases even more. With a properly selected power, a long burning stove will delight you with its warmth. In general, the operation of such a device is possible without using a water circuit. On the other hand, its installation will provide the most favorable conditions associated with the use of different heating networks.

Unlike brick ovens, attaching a water circuit to a metal structure with your own hands is much easier. The heat exchanger is installed above the firebox, thereby bending around it, will provide water heating. Circulating through radiators and pipes, the coolant is able to warm up a country cottage more efficiently. Thus, the use of a metal oven is best combined with a water circuit. However, it is better not to use a heat exchanger with brick structures due to the complexity of installation and nuances during the operation of the device.

A feature of installing such stoves with your own hands is their installation in a specially designated place using adjustable legs and connection to the chimney through an outlet pipe, usually located at the back of the stove. An important factor is the ability of such heating devices to be integrated into an existing heating system. The possibility of installing an autonomous network based on gas or electric boilers and, as an addition, the integration of a solid fuel unit with a water circuit. This heating system will allow you to have a spare heat source in case of unavailability of the main one.