Universal Gas Generator Brown HC12 / 24V-PRO

Instruction for installation and operation of the Brown Gas Generator - download ...

Application: Hydrogen generator (HHO generator) suitable for cars, vans, trucks, agricultural and construction equipment with engines from 1000 to 4000 cc. see. The hydrogen generator complies with the Bulgarian State Standard (BDS). It has been tested in a laboratory and underwent a conformity assessment procedure in accordance with Directive 2006/95-EC of the European Parliament. Marked with the European initials of conformity CE2024.

Brown Gas Generator

Operating voltage: 12 V - 14 V Power consumption: 10 A - 30 A Brown Gas production: 120 liters per hour. Fuel economy: 15% - 40% Electrolyte freezing temperature -25 degrees Celsius Warranty: 24 months (depending on operating conditions) All Brown Gas Generators manufactured by us are based on the HC12 / 24V Pro model. The modifications differ in input signals and sensors for registering control signals. Brown Gas Generator Package: 1 Hydrogen Cell 2. Magnetic Sensor (for Diesel Engines) / Inductive Sensor (for Gasoline Engines) 3. Water Filter / Expansion Tank 4. PWM Process Controller 5. Relay - 40A 6. Cables 7. Hoses 8. Electrolyte

Contacts - Order ...

Price list …

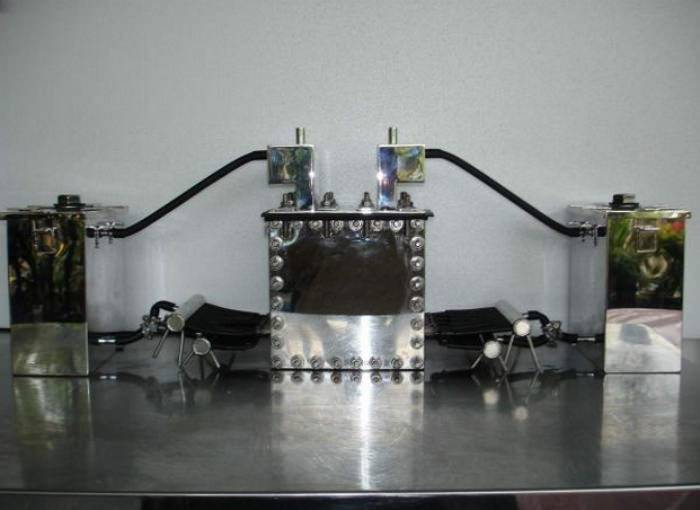

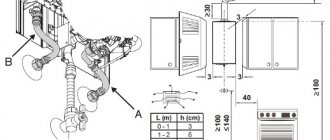

Electrolyzers HC12 / 24V Pro

1. Operating voltage - 11-14.02 V 2. Load current 5 to 30 A 3. Operating temperature –15 to +50 degrees 4. Consumption current - level meter: - 5. Electrolyte concentration (KOH) - 10 - 14% 6. Gas Brown productivity up to 2 l / m. 7. Overall dimensions (mm): H = 220, L = 205, W = 175 8. Material 8.1. Box - polypropylene

8.2 Electrodes - Steel 316L

Brown Gas Generator

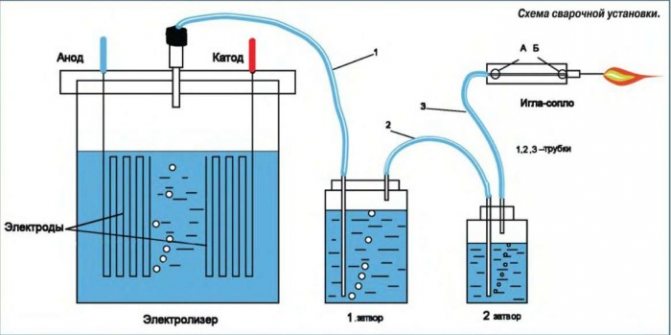

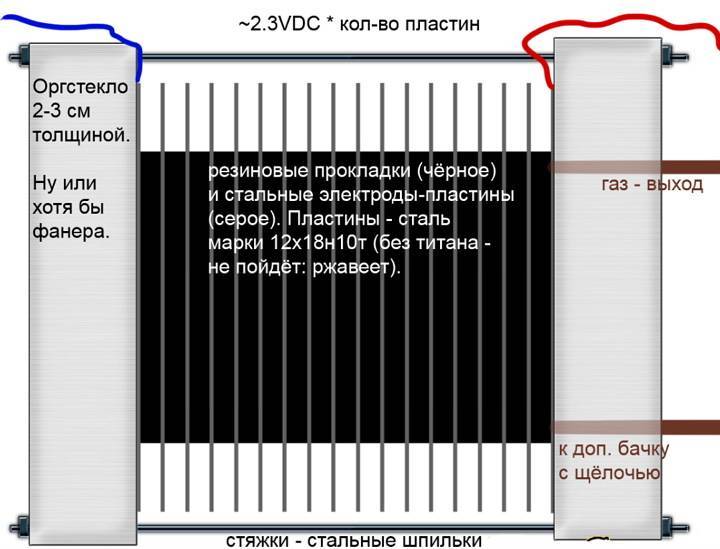

Electrolyzer - a device in which the electrolysis process is carried out electrochemically and as a result Brown's Gas is released. The electrolyzer box is made of polypropylene - a material with good resistance to temperature changes, vibrations, stress and aggressive chemical environment. It has the shape of a classic battery. Consists of box, top cover, fittings, valves and level meter. Inside there are electrodes through which electrolysis is carried out. They are made from 316L steel. The electrodes are powered through stainless steel pins - A2 (grade 304). The assembly uses stainless steel washers and nuts. To improve the electrical conductivity outside the box, the nuts and washers, with which the cable glands for the electrolyser supply are pulled together, are made of ordinary galvanized steel. The electrolyzer is covered with stickers that indicate the purpose of the holes and fittings. The power terminals are marked with plus and minus and are directly imprinted on the plastic of the box. The electrolyzer also has an information sticker with the name of the product and information and coordinates of the manufacturer. The inscriptions are in Bulgarian and English.

Contacts - Order ...

Price list …

Profit for the dishonest

How much happiness helium balloons bring. There are few children who can resist a multi-colored miracle. Yes, and the holidays are now not complete without helium balloons, which immediately soar up, it is worth letting go of the thread for a second.

Today a helium cylinder costs a lot of money, and some careless sellers decide to save money. After all, not only helium, hydrogen can make the balloon fly. Acetylene is also lighter than air. But are these savings really safe for the customers themselves?

Recently, the news about the explosions of balloons has been heard more and more often:

- May 2012 - Yerevan;

- October, 2020 - Kuzbass;

- October, 2020 - Kemerovo.

These are only three known cases, in one of them, namely at a rally in Yerevan, the balloons were filled with hydrogen, which could go out and accumulate in the air, mixing with oxygen. And we know that such a mixture in a certain proportion is called an explosive gas. People suffered in this tragedy.

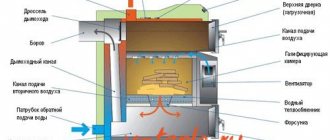

Process controller with PWM for NVO generator PC12

1. Operating voltage 13/28 V 2. Operating frequency - 1-3 kHz 3. Output current - <40A 4. Operating temperature - from -15 to 80 degrees 5. Adjustment method - pulse-width modulation 6. Control frequency. signal for speed control 10-350 Hz

7.Controlling ex. - 0.8 - 4.5 V 8. Box material - polystyrene 9. Dimensions (mm) - L = 199.4, H = 43.2, W = 84

"Process controller with PWM"

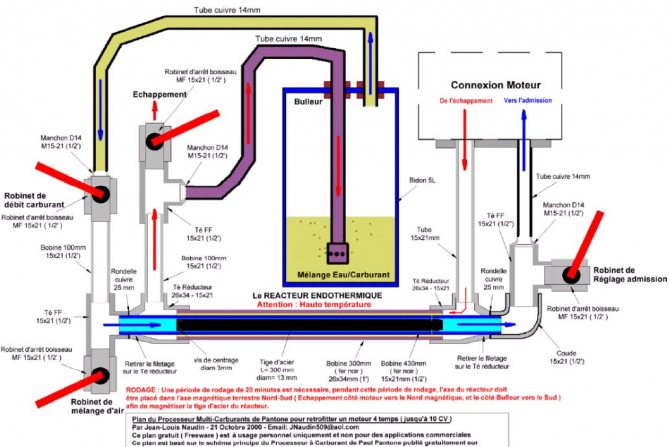

Process controller with PWM is a device that controls all processes occurring during the operation of the Brown Gas Generator. It regulates the amount of current depending on the mode in which the car's engine is at the moment. For example, at idle, the current taken from the alternator is 5-8 amperes, and at more than 2000 rpm it can be 18-30 amperes (depending on the engine size). The controller is controlled by signals that are generated by the car or by a sensor that monitors the speed of the car that we manufacture. We have two types of "Process controller" - operating at 12-14 volts and 24-28 volts. The regulator is controlled in several ways: - from the speed signal, which is taken from the car's alternator or from any sensor - for example, a crankshaft or camshaft, from an external sensor provided by us or from a frequency signal that is generated by induction from the voltage passing through any plug cable ignition of the car. This signal is applied to a thin cable that runs between two thick cables from the input side of the controller. On some Gasoline Vehicle Process Controllers, there is an output cable to which can be supplied as a voltage control signal from a TPS sensor located on the throttle valve. In principle, the signal there has a voltage of 0.8 to 4 volts. After applying this voltage, no controller settings are required - with this signal, it will work fine. After giving the appropriate signal, the Process Controller will start to work in a certain state according to the incoming signals. For fine tuning, you need to open the controller box and tune it according to your needs. This is done by moving

jumpers located on the motherboard. The controller supplies current of varying magnitude to the electrolyzer - in the range of 4 - 30 amperes. Process controller ”is placed in a plastic box. The “Process Controller” is designed so that it supplies current to the electrolyzer after starting the engine and starting charging the battery with a current of more than 13.2 volts. This is done in order not to load the alternator of the car at the beginning of work, so as not to take current from the battery and use only the free current produced by the alternator to obtain HHO gas. This function of the controller also acts as an overload protection - when many devices are switched on in the car, the voltage used to charge the battery drops and if the value falls below 13.2 volts, the controller turns off the Brown Gas Generator to prevent the generator from overloading. New Process Controllers which are made with a single-case microprocessor are configured by a computer using a programmer that we provide and software that we have developed.

Contacts - Order ...

Price list …

The history of the discovery of hydrogen

The release of combustible gas during the interaction of metals and acids was observed as early as the 16th century, that is, during the formation of chemistry as a science. The famous English scientist Henry Cavendish studied the substance since 1766 and gave it the name "combustible air". When burned, this gas produced water. Unfortunately, the scientist's adherence to the theory of phlogiston (hypothetical "superfine matter") prevented him from coming to the correct conclusions.

The French chemist and naturalist A. Lavoisier together with the engineer J. Meunier and with the help of special gas meters in 1783 carried out the synthesis of water, and then its analysis by means of decomposition of water vapor with red-hot iron. Thus, scientists were able to come to the correct conclusions. They found that "combustible air" is not only a part of water, but can also be obtained from it.

In 1787, Lavoisier put forward the assumption that the gas under study is a simple substance and, accordingly, belongs to the number of primary chemical elements. He named it hydrogene (from the Greek words hydor - water + gennao - I give birth), that is, "giving birth to water."

The Russian name "hydrogen" was proposed in 1824 by chemist M. Soloviev. The determination of the composition of the water marked the end of the "phlogiston theory". At the turn of the 18th and 19th centuries, it was found that the hydrogen atom is very light (in comparison with the atoms of other elements) and its mass was taken as the main unit for comparing atomic masses, having received a value equal to 1.

Synchronizer of signals of control mode "Process controller"

1.Input voltage: 12-14V 2.Output signal - voltage - 2-14V 3. Current consumption: This device is completely our development and represents a revolutionary discovery that increases the efficiency of the Brown gas generator by several levels and ensures accurate dosing of Brown Gas and delivery it to the engine.

The synchronization block serves to summarize and control signals with the help of which the two-stage operation mode of the “PWM process controller” is regulated. We take two types of signals from the engine - the signal of the engine operating mode (this signal shows in which mode the engine is currently operating) and the engine load signal (the signal indicates the engine load at the moment), process them in the device and generate a control signal for the Process Controller ”Which probably most adequately doses the amount of Brown's Gas that must be delivered for maximum efficiency. Hydrogen cell optimizer (Optimizer is a device whose role resembles the function of a turbine in an internal combustion engine). The Hydrogen Cell Optimizer is a unique device that: - improves the efficiency of the Brown Gas Generator by approximately 20%; -increases the productivity of the water cell up to 15%; -speeds up the transmission of Brown's Gas to the engine several times; -increases the dynamics of the engine running on Gas Brown; -Provides better assimilation of HHO gas by the engine; -decreases the temperature of the hydrogen cell; -increases safety; Recommended for vehicles with large engine displacement and used for professional transport activities - minibuses, buses, trucks, agricultural and construction equipment.

Contacts - Order ...

Price list …

Magnetic sensor - DN

(DU - sensor with increasing output voltage, DN sensor with decreasing output signal)

HHO generator sensor

1.Supply voltage: 12-14V 2.Output signal-voltage - 2-14V 3.Frequency of the output signal - 30 - 350 Hz 4. Current consumption: RPM sensor DU and DN is a device that registers the speed of the car engine and sends control signals to the "Process controller". The RPM sensor is a device that registers changes in the magnetic field with its sensing element. Opposite the sensor, magnets are attached to any of the engine pulley, which rotates in proportion to the revolutions of the crankshaft. As the magnets pass in front of the sensor, they change the magnetic field, and these changes are recorded by the sensor and generate frequency and voltage signals that control the process controller.The sensor is installed in a plastic box. A luminous indicator is installed on the cover of the sensor, which shows its operating mode. Powered directly from the vehicle battery to avoid confusion and power spikes when the vehicle engine is running.

Contacts - Order ...

Price list …

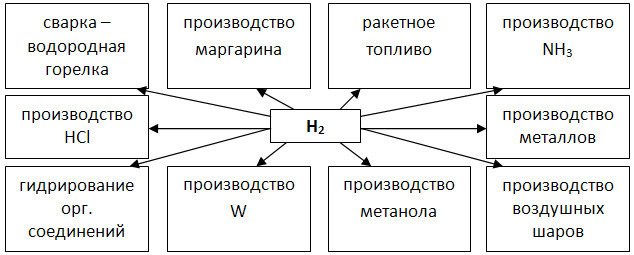

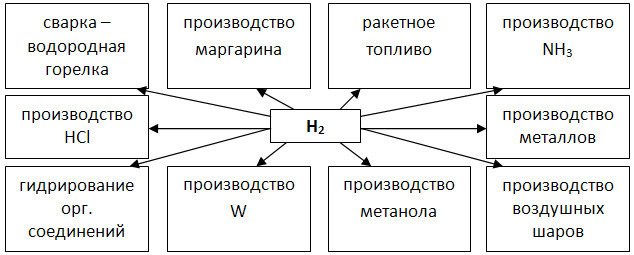

Application of hydrogen

This material began to be obtained industrially at the end of the 18th century. Then it was used to fill balloons. At the moment, hydrogen is widely used in industry, mainly in the chemical industry, for the production of ammonia.

Mass consumers of the substance are producers of methyl and other alcohols, synthetic gasoline and many other products. They are obtained by synthesis from carbon monoxide (II) and hydrogen. Hydrogene is used for the hydrogenation of heavy and solid liquid fuels, fats, etc., for the synthesis of HCl, for the hydrotreating of petroleum products, as well as for cutting / welding metals. The most important elements for nuclear energy are its isotopes - tritium and deuterium.

Inductive spark plug control

An inductive sensor is designed to register the operating mode of gasoline engines by signals generated inductively from the plug cable of a car. Designed for gasoline engines. The cable of any candle is wrapped in a silicone cable in which a voltage is induced. The sensor registers this voltage as

frequency signal. The signal is converted into a voltage which controls the operation of the "Process controller". Thus, as the engine rpm increases, the production of Brown Gas is regulated, which is supplied to the engine.

1.Supply voltage: 12-14V 2.Output signal-voltage - 2-14V 3.Frequency of the output signal - 30 - 350 Hz 4. Current consumption: Level meter - LM1 1.Supply voltage: 12-14V 2. Current consumption:

Contacts - Order ...

Price list …

Generator Usage Questions

During the assembly of the device, some questions may arise. We will answer the most common ones.

Which water is preferable: distilled or from the mains?

Unrefined is quite acceptable, but it should be of sufficient quality - it should be free of heavy metals. The best option is to use distilled water with the addition of sodium hydroxide. Proportion: in a bucket of water - a tablespoon of the additive. Sodium hydroxide must be mixed well in water.

What metal should be used in the construction of the apparatus?

Some instructions state that the generator is best assembled from rare (and therefore expensive) metals. This is not true. Stainless steel that is not subject to oxidative processes is also suitable. Among the grades of steel, ferromagnetic steel is distinguished by excellent characteristics. All kinds of debris do not cling to this metal.

How often do you need to change the electrode plates?

These parts are not subject to any chemical or mechanical stress. So I don't need them.

Do the electrode plates need preparation?

Yes, it must be done. It is recommended to wash the plates in soapy water. Further, the surface of the plates must be treated with a cloth soaked in alcohol or vodka. The electrolyzer should work for some time in test mode. In this case, it is necessary to regularly change the contaminated liquid to a clean one. The test period continues until the water has washed off all the dirt. If the device is assembled correctly, then during its operation the liquid and plates will not overheat.

Assembling a Brown generator with your own hands will require effort and a certain skill. Whether it works or not depends on many factors, but it's definitely worth a try. If successful, the resulting Brown gas will increase the energy independence of your home.