Type of autonomous heaters for diesel fuel

According to the established terminology, autonomous diesel heating units are divided into the following types:

- small stand-alone diesel oven;

- powerful diesel thermal furnace (heat gun);

- self-made autonomous stove with diesel fuel;

- the stove is a dropper powered by diesel fuel.

Any stove with diesel fuel has its own advantages and disadvantages. To evaluate each of them, you need to understand the characteristics of such devices.

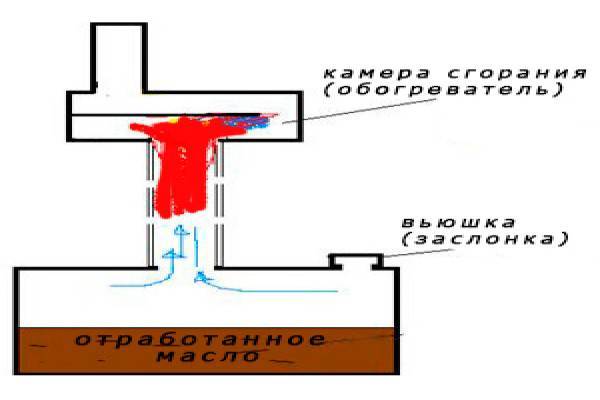

Waste oil dropper stove

Waste oil is one of the cheap fuels. The stove can heat up to 800-900 ° C. At the outlet, the temperature will be 90 ° C.

Pour in a portion of oil and add 50-100 g of a fuel (special fluid, heating oil, kerosene or diesel fuel). This is necessary to quickly ignite the stove. Wait until the combustion process stabilizes. Then you can pour the next portion.

If there is oil spilled, it must be removed immediately. Combustion takes place inside the pipe. This is a safe process. Fuel consumption from 0.5 to 1.5 liters per hour. When the stove is on fire, you can heat the water.

Waste oil dropper stove

This is important to know: fuel for drip furnaces must fit into the "oil" category.

Recommended for use: diesel oil, fuel oil, waste oil, heating oil. Do not use - gasoline, acetone or other solvents. Avoid getting water into the fuel.

In the special literature there are a large number of detailed instructions on how to make a do-it-yourself drip oven. Each of these designs is unique and has its own advantages and disadvantages. You can also use the store version of the stove, but modify it at your own discretion.

Watch an overview video about the diesel fuel dropper stove:

video

https: https: //youtu.be/p0yBevftIlo

Furnace characteristics

All types of autonomous diesel fuel stoves can be divided according to the following criteria:

- heating method;

- constructive scheme;

- allocated power;

- diesel fuel consumption rate;

- the possibility of connecting additional heating devices or systems;

- weight and size characteristics.

Stove stove

By the way they are heated, they can be divided into two broad categories:

- autonomous devices using direct heating;

- devices using indirect heating.

A feature of direct heating devices is the absence of an equipped chimney. They are called "potbelly stoves".

The most widespread devices are indirect heating.

A homemade diesel stove is assembled according to one of the following schemes:

- double-circuit or as it is called gas-air;

- wick;

- drip;

- using steel sheets;

- using an ordinary gas cylinder.

Homemade stove on diesel fuel

In terms of the heat output and the diesel fuel consumption rate, factory-made units start from 2.5 kW with a consumption of 180 milliliters of diesel fuel per hour and up to 20 kW with a capacity of 550 m3 per hour. The consumption of diesel fuel increases by 1.5 liters. These units are called heat guns.

Possibility of connecting additional heating systems, such as air ducts. The continuous operation time varies depending on the characteristics. This time varies from 6 to 28 hours of operation without refueling.

Two types of commercial stoves

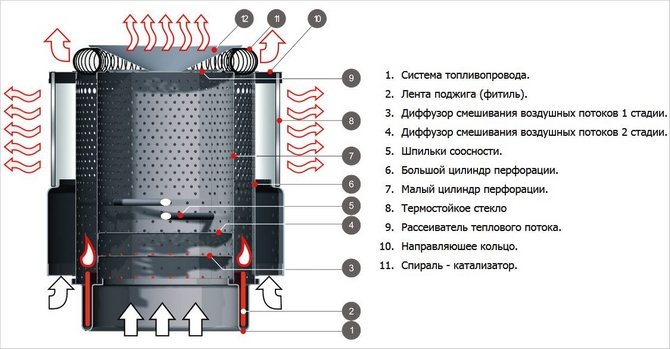

Miracle stove

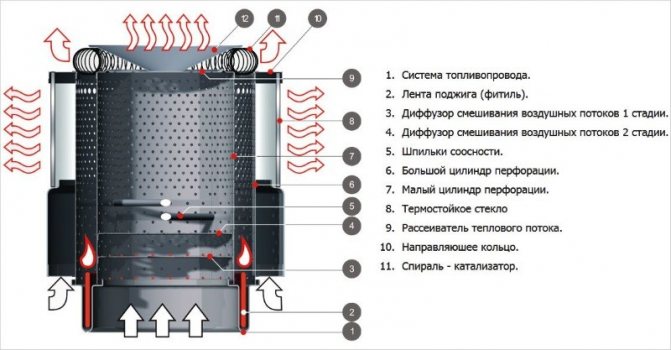

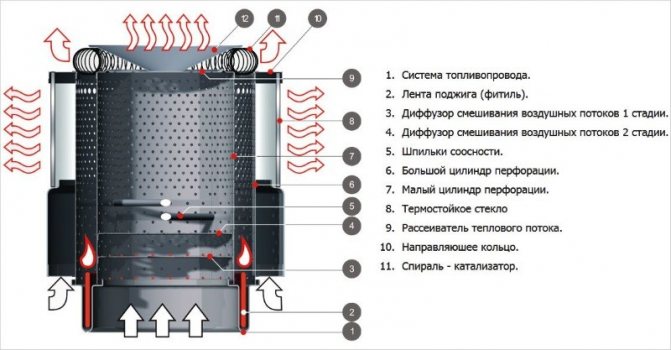

The original name was invented by sellers and manufacturers to attract buyers.There is little miraculous in such a unit, since it is the heir of the familiar kerogas... The mini-unit pleases the user with low consumption of diesel fuel. The small size of the stove and its weight (no more than 10 kg), simplicity of design and ease of operation have made models of this type popular. The burner of the furnace is made in the form of a wick, the lower part of which is immersed in a container with liquid fuel.

When the valve is opened, diesel or kerosene is supplied to the working tank, the wick wound around the cylinder absorbs the fuel. The fire is ignited manually, waiting for some time for warming up and setting in operating mode. The power is increased or decreased by a valve, with its help the unit is turned off.

The wick stops burning after about 7-10 minutes, when all the fuel on it has burned out. Manufacturers have tried to create maximum comfort by installing a grate for heating a container with water. If a diesel fuel heater is used regularly, then the burner is constantly cleaned and the wicks are replaced, which are considered consumables and their cost is low.

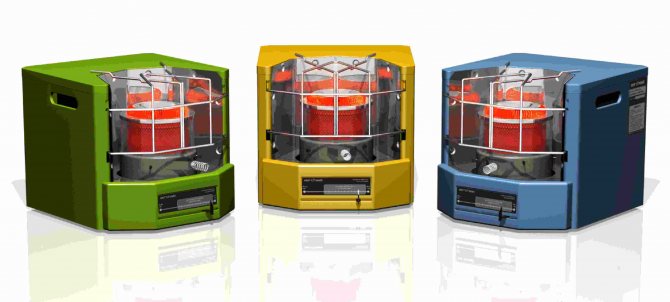

Thermal diesel guns

For quick heating and warming up of premises, the floor area of which exceeds 20 m², heat guns are purchased in the retail network, with fuel in the form of diesel fuel. The air heats up faster due to the fan blowing it in the heating area. The burner is a wick or torch similar to the previous case. The fan is located at the back of the burner and blows the air flow.

A reflector is placed in the front part for safety, fuel is pumped from a tank located on a movable base. Air cannons are divided into two types:

- direct heating;

- indirect heating.

Their difference lies in the organization of the removal of combustion products. In the first case, the smoke goes into the room and is removed with natural ventilation, the second option provides for the device of a simple chimney of their pipes. The second option is more expensive, but its use is less safe for human health.

The design of the stoves is presented in a general way, manufacturers offer convenient innovations depending on the various accessories of the model range. The body of the units is made of refractory stainless steel, all models are easily transported to the desired location.

Model cost

Units of this technology are produced in a budget version, so the cost is low for a miracle stove with diesel fuel. The price of various options for stoves has a price range from 1 thousand 750 rubles to 5 thousand rubles. The price formation is influenced by the power of the unit, size, type of gas outlet, manufacturer. Wicks cost 10 rubles per piece.

Some features of such a furnace

The features of a homemade diesel stove can be divided into two categories:

- manufacturing features;

- application features.

Features during manufacture are determined by the choice of the design of such a stove. This will require the selection of a certain material (appropriate steel: sheet, angle, pipe), certain finished products or home-made production (nozzles, pipes, chimneys and air ducts), containers for diesel fuel. The need to use the appropriate tool and metalworking equipment (drill, grinder with a set of cutting wheels, welding machine) hardware for fastening individual parts of a homemade stove.

Application features include: the specifics of the ignition of such a stove, the organization of the removal of combustion products. Using diesel fuel as fuel will require periodic maintenance of the existing nozzle and burner. This is due to the presence of sulfur in the diesel fuel.

If a diesel fuel stove is used in which the fuel flows by gravity, it is necessary to place the diesel fuel tank above the burner itself at a certain distance in order to exclude its uncontrolled heating.

Fuel consumption for heating

The amount of diesel fuel that the boiler will consume every hour during the coldest period of the year should be calculated using the formula:

P = Q / (q * efficiency),

Where

- P is the hourly fuel consumption, l / h;

- Q is the heat loss of the building at the lowest outside temperature, kW;

- Q is the lowest heat of combustion of 1 liter of diesel fuel, we take q = 12 kW * h / l;

- Efficiency - coefficient of efficiency of the installation, we take efficiency = 0.92.

Determining the heat loss Q is not an easy task. Today, a widespread misconception is that it is enough to multiply the building area by 0.1 kW for this. That is, a house with an area of 100 sq. m will lose 10 kW of heat, with an area of 200 sq. m - 20 kW, etc.

To understand that this technique is extremely inaccurate, it is enough to take into account at least the fact that for buildings located at different latitudes and, accordingly, in different climatic conditions, the value of specific heat loss simply cannot physically be the same.

A complete calculation of heat loss takes into account a number of factors:

- the lowest temperature in winter;

- thermal conductivity of enclosing structures (depends on the properties of the base material and insulation);

- the total area of window openings;

- the orientation of the building relative to the cardinal points (the amount of solar heat entering through the windows depends on this);

- the amount of heat generated by the equipment in the building.

It is most correct to order such a calculation to an experienced engineer - an employee of a construction or design firm. But if you wish, you can master it poorly on your own. To do this, you will need to read specialized literature or look into SNiPs "Heating, ventilation and air conditioning", "Construction climatology", etc.

If the boiler is also used for heating water, then it will be necessary to add the heat expended for this Qw to the heat loss Q. This value is determined by a simple formula:

Qv = (s * m * dT) / (3600 * 1000),

Where

- Qw - average heat consumption for water heating, kW;

- С - specific heat capacity of water, J / kg * С;

- M - mass average hourly consumption of hot water, kg / h (daily consumption should be divided by 24);

- dT is the temperature difference between heated water and cold water entering the house, C.

The above formula cannot be used to calculate the total fuel consumption for the season, as it only takes into account the coldest winter temperatures. To determine the supply of diesel fuel for the winter, the consumption P is usually halved. For example, if the amount of heat loss in the coldest five-day period according to the calculation results was 18 kW and the hourly fuel consumption under these conditions is

P = 20 / (12 * 0.92) = 1.81 l / h,

then the total consumption for a heating period of 200 days will be:

Ptot = (P / 2) * 200 * 24 = (1.81 / 2) * 200 * 24 = 4344 hp.

Note that the accuracy of this technique also leaves much to be desired. It would be more correct to determine the flow rate based on the average winter temperature typical for a given region.

What objects can be heated by a miracle stove?

Modern stoves that use diesel fuel as fuel, regardless of their shape and design, are capable of heating various rooms. They successfully cope with the task of maintaining comfortable temperature conditions in the following buildings:

- suburban buildings that do not have supplied communications;

- separate rooms of residential suburban buildings;

- additional country buildings (sheds, outbuildings);

- outbuildings, basements, basements;

- garages, workshops;

- stand-alone greenhouses and hotbeds;

- they can heat individual tents and campgrounds.

Which diesel stove should you choose?

When choosing a garage oven that is powered by diesel fuel, a number of characteristics should be taken into account, such as the power of the stove, the material of manufacture, the ability to use at different times of the year, the price factor, etc.

Criteria

Power

Based on these data, and knowing the area of \ u200b \ u200bthe premises of your garage, you can calculate what kind of stove you need to purchase or manufacture.

Manufacturing material

Such devices are made mainly of steel - metal sheets and corners using welded joints. There are also homemade drip-type ovens, which are made from pipes or old gas cylinders.

The lower hemisphere of such a cylinder is used as a bowl where combustion occurs, and the fuel tank is taken out of the body, diesel fuel is dosed to the flame through a metal tube, which excludes spontaneous combustion.

Price factor

Prices for diesel heaters for a garage are quite low, as well as for diesel fuel or fuel oil, and every motorist has used oil at hand. From an economic point of view, such a heating device will be the best option.

Other points

- An important point is the presence of a viewing window (plug) at the stove. This allows you to control the combustion process and increase or decrease the supply of the air mixture to the compartment where the fuel is combusted.

- In terms of their dimensions and installation method, diesel ovens can be both large stationary and small portable. The choice here is huge and everyone can choose a unit based on their specific needs, goals and objectives.

Popular models

- Multeat Eco 18. The model runs on used engine oil. Its cost is 21,500 rubles. The furnace does not include a fuel tank; any tank with a tap and a fuel filter can be used as it. There is a control system for fuel supply to the combustion plate.

- Solyrogaz PO-2.5 Compact and inexpensive stove powered by diesel fuel. It will cost the buyer only 3,300 rubles and can heat a room up to 25 sq. meters, its power is 2.5 kW. It is very popular with hikers, summer residents and owners of small garages.

- Ritsa. A budget version of the oil-fired furnace. With a heating capacity of up to 150 sq. meters, its price will be only 7000 rubles. There is a chimney and a fuel tank with a volume of 10 liters.

- Polarus. A powerful heating unit for large rooms, the fuel used is used engine oil. This 60 kW oven is capable of heating 3000 cubic meters of air per hour. Price - 65,000 rubles.

- Multeat MUL. Another solid device for large areas in the form of a convection oven, running on old machine oil. Its cost is 56,500 rubles. Multeat MUL is capable of working both on mining and on a mixture of diesel fuel and oil. Recommended for rooms with a volume of up to 800 cubic meters.

Precautions

The use of homemade stoves on diesel fuel is always associated with the presence of an open fire. Therefore, certain precautions must be taken. They will allow you to avoid many troubles and even tragedy.

Garage stove

These precautions are fire safety measures:

- the stove must not be installed in places where drafts are possible (they contribute to the activation of the combustion of the mixture);

- it is necessary to create a space around the stove (approximately 1.5 meters), free from combustible and flammable objects (especially this must be provided in a garage or workshop);

- provide access to a fire extinguisher;

- chimney length must exceed 4 meters;

- after using the stove, it is necessary to clean and prevent it;

- for residential premises, it is advisable to use factory-made diesel fuel stoves that have special permits.

Features of ignition and maintenance of furnaces. Safe operation rules

Before firing up the furnace, inspect the lower container for the presence of water in it.If necessary, moisture is removed, after which 1-2 liters of used engine oil are poured into the module through the filling opening. Fuel is ignited through the same hole using a steel wire wick and oiled rags. After the oil has ignited (usually it takes from three to five minutes), the air supply hole is closed, leaving a gap of 1–2 cm wide. In this case, intensive evaporation of the combustible substance is observed, due to which the furnace operates at maximum power.

It should be remembered that an oil stove, like other heating equipment with an open flame, is a fire hazardous structure. During the operation of a liquid-fuel stove, you should adhere to the rules of safe operation:

- Preparing the oven for operation must necessarily include checking the presence of traction. For this, a lighted match is brought to one of the holes of the burner. If its flame deviates inward, then you can proceed to ignition. Otherwise, it will be necessary to clean the ducts of the unit and the chimney to ensure a normal vacuum.

- It is forbidden to shake the working off before refueling. Water or antifreeze that gets into the oil leads to splashing of fuel through the burner injection holes.

- The fuel level should be no more than ¾ of the height of the primary chamber. It is better to fill the oven beforehand. This will allow the oil to settle.

- It is prohibited to use gasoline, thinners and other flammable liquids for ignition. Better to use diesel fuel or kerosene, which moisten paper or rags.

- Any oil spilled near the heater must be immediately removed from the floor.

- It is strictly forbidden to use water to reduce heat or stop oil burning.

We should not forget about fire extinguishing means. There must be a fire extinguisher and a container with sand near the stove.

How does it work

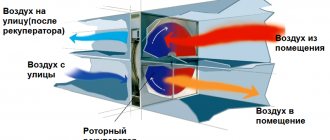

The main physical principle on which almost all diesel stoves work is the principle of converting combustion energy into thermal energy. Diesel fuel usually flows by gravity into the chamber, where it mixes with air and is heated. This mixture then enters the combustion chamber.

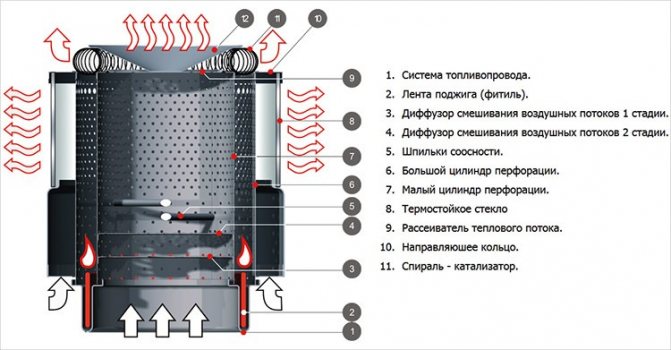

The device of the miracle oven

In this chamber, when it burns, it heats either the walls or a special heating element that serves as a heat exchanger. Combustion products are discharged through a special chimney to the outside. In addition to the stove itself, such a chimney also serves as a heat exchanger and heats the ambient air in the room.

Solid Fuel Miracle Furnace

The traditional rustic miracle oven is only suitable for large structures. This is due to the fact that such a design is very large, and besides, it cannot boast of high efficiency. However, at the present time, it makes no sense to lay out a bulky stone stove, because you can equip a compact and efficient stove with your own hands.

Potbelly stove

This is a well-known type of compact miracle oven, which has been helping residents for many years to heat houses, garages, greenhouses, etc.

The design of the stove is very simple. By and large, it is an iron barrel with dense walls.

It is not difficult to create a furnace out of it, the main thing is to prepare in advance all the drawings in accordance with which the work will be carried out. You can use any container or even make a metal box yourself. The main thing is to comply with the condition - volumes and power should be enough to supply heat to the required area.

It is recommended to choose a barrel with a capacity of approximately 100 liters. Its internal cavity must be divided into two different-sized tiers. One of them will act as a fuel combustion chamber, and the other is intended for the accumulation of waste.For separation, a horizontal straight plate made of strong metal is used, the thickness of which must be at least 5 m.

It is very important that the size is chosen in accordance with the requirement, since if the thickness is less than 5 m, then the metal will not be able to withstand the loads from the heating of the case. You must drill large holes in this plate. This is necessary so that the ash can easily enter the second compartment.

The ash pan is equipped with a pull-out metal drawer so that combustion products can be removed without hindrance. The front wall of the barrel is arranged in this way: in it you have to cut two holes, one for the combustion chamber, measuring 40 * 40 cm, the other for the ash pan. This hole should be ¼ less than the first. You can do this with a gas burner or a conventional chisel and hammer. The opening of the firebox should be equipped with a convenient door with a latch.

The upper section of the stove must be well closed with a metal cover, in which a wide hole is drilled for the chimney pipe. Use a welding machine to secure the cover firmly. At the end of all installation work, the finished potbelly stove must be placed on the legs or a foundation made of refractory bricks so that the floor under it does not ignite.

Of course, the potbelly stove has many disadvantages:

- firstly, it does not differ in high efficiency. This is due to the fact that a large amount of heat escapes through the chimney;

- secondly, the structure cools down quickly due to the fact that steel is characterized by high thermal conductivity and begins to give off heat to the air as quickly as possible;

- in addition, the fuel supply in the combustion chamber must be constantly replenished.

But despite a number of shortcomings, this version of the miracle oven is considered the most economical. It does not require any costs and you can build a wonderful wood-fired oven with your own hands in a couple of hours.

Do-it-yourself stove design

For independent design, it is necessary to have minimal knowledge in the field of thermodynamics (in order to understand how the formation and combustion of a combustible mixture of diesel fuel and oxygen is carried out), to be able to understand elementary drawings. It is desirable to have the simplest skills in the field of processing ferrous and non-ferrous metal (cutting, drilling and welding technology). If you don't have such experience, you can always contact a specialist.

A diesel fuel stove with your own hands can be made in a garage, home workshop.

Construction from a conventional gas boiler

Elements of an old gas boiler can be used as a body. The boiler body must be cut into two halves. One will be the bottom of the stove, the other will be on top. The nozzles available in it must be expanded in order to ensure free supply of diesel fuel into the mixing chamber and further into the combustion chamber.

Homemade stove from a gas boiler

The duct system can be converted into a chimney. It remains only to place the tank with diesel fuel and the stove is ready.

Gas cylinder heater

An unused gas cylinder can be used as the body of the future stove. Before using it, you need to make sure that it is empty. In addition to the cylinder, you will need two pipes with a length of about 4 meters and an outer diameter of about 100 mm, a container for storing diesel fuel (on average from 10 to 15 liters), two copper pipes (for the production of a burner). The support should be made from steel corners with a 200mm shelf. In addition to the material, you will need tools: a drill and drills for metal, a grinder (grinder) with cut-off wheels, any welding machine.

Using a grinder, the cylinder is cut into two equal parts. The upper part will be the cover of the future stove, the lower one will serve as a combustion chamber. For the stability of the entire structure, metal corners are welded from below, which are the legs of the future stove.

A hole is made in the upper half. An exhaust pipe will be installed in it. It must be welded securely.Make sure that it is located strictly vertically. A hole is made in the pipe. It functions as an air intake regulator.

Having departed from the pipe about 10 cm, make another hole up to 3 mm in size. There should be at least ten such holes. The latter should be at a distance from the welding point no more than 50 centimeters. In addition, a hole with diameters up to 8 centimeters is prepared in the upper part for pouring diesel fuel. A hole 5–8 cm in size is made in the upper part of the cylinder for filling the fuel.

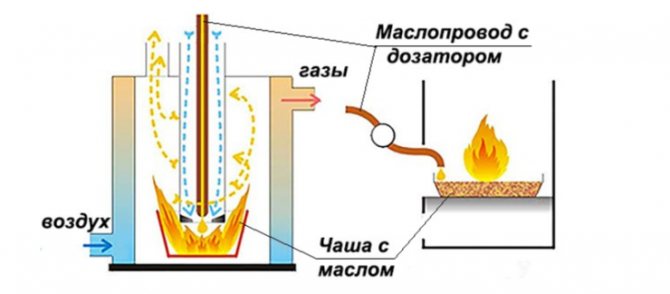

Drip stove

They are quite economical and easy to manufacture. For example, to obtain a power of 10 kW, a diesel fuel consumption of only 0.6 liters per hour is required. By increasing the size of the structure, the heat transfer power can be increased to 20 kW.

The technology for manufacturing a dropper stove on diesel fuel does not present any particular technical difficulties. First, the dimensions of the future unit are calculated. The calculation is based on the following considerations. For heating a room with an area of 9 sq. m, there will be enough stove, the dimensions of which are equal to 30x30x45 cm. These dimensions allow you to calculate the volume of the stove itself. Most often, they use ready-made structures and not necessarily rectangular. For small stoves, the lower parts of fire extinguishers are used, for more powerful stoves, the bottom of metal barrels is used.

The supply of diesel fuel is organized using elements of a medical burner. The rubber hose present in it is fixed on a specially prepared copper tube. This tube is bent at right angles. Then it is fastened with a clamp or a specially prepared fastening. As a wick, you can use an improvised rag, which is pre-impregnated with diesel fuel.

Homemade stove dropper

The principle of operation of such a stove is to constantly wet the wick with diesel fuel, which flows by gravity through a hose and tube from a container with diesel fuel.

A door is made in the stove body, and a hole is made on top for a copper tube.

Steel sheet stove

It is shaped like two metal discs. There is a steel pipe between them. Several holes have been drilled in it. They are designed to supply external air from below and remove harmful combustion products.

Typically, such a unit has a fairly compact size. The specifics of the design make it safe enough. Another advantage of such stoves is their efficiency. This is due to the fact that the fuel mixture burns out completely and the most efficient heat transfer occurs.

For the manufacture of such a furnace, you will need sheet steel with a thickness of at least 5 mm, a steel pipe. It needs to be cut into two shorter pipes and two bends made. They must be made in such a way that it is possible to insert one into the other. After connecting these elements, a chimney design is obtained. I make two containers from steel. One, the lower one, serves as the firebox of the stove itself, the second upper one is the fuel tank. The size of the tank is determined by the manufacturer himself. Usually its volume does not exceed 12 liters. This is due to the convenience of pouring diesel fuel.

The location of the tank above the level of the combustion chamber is based on the principle of diesel fuel supply. It flows by gravity. In a special chamber, diesel fuel is mixed with air and heats up. Thus, a combustible mixture is formed. Further, the combustible mixture enters the combustion chamber. In it, during combustion, the spiral heats up. This coil acts as a heating element. With proper operation, it heats up to a temperature of about 800 ° C.

DIY heater

Of course, a diesel stove for residential premises, garages, greenhouses and other small objects can be purchased in a store. The prices are reasonable. But you can make an equally high-quality model yourself.

There are several types of stoves for kerosene, diesel fuel or waste oil, that is, liquid fuel. Each has its own advantages and disadvantages.

A do-it-yourself liquid-fueled stove will not differ much in quality from the one purchased in the store

From two tanks

This version of the stove consists of two round or rectangular parts. Waste oil or diesel fuel is poured into the lower one, made in the form of a container with legs. Here, liquid fuel, evaporating, goes through the stage of primary combustion. The lower tank is connected to the upper one by means of a perforated pipe, in which secondary combustion takes place. A plurality of holes are made in the pipe itself, which carry out the supply of secondary air.

The lid on the lower container has two holes: for filling fuel and with a damper that helps to regulate the intensity of combustion. The combustion itself is carried out due to the natural supply of air, that is, draft.

Such a furnace has a high efficiency and heats the room well, but has a number of disadvantages.

Firstly, when even a small amount of water gets into a combustible liquid, unpleasant loud exhaust begins to occur, often with flames or sparks from burning oil, which can cause a fire.

Secondly, both during ignition and during operation, such a model spreads an unpleasant odor. This can be a serious problem when using the stove in a residential area.

Such a modification does not require the use of special materials and can be made from available raw materials. This explains its immense popularity.

More about the cylinder stove:

Dropper model

This version of the stove, although it is technically more difficult for homemade production, is safer and more efficient. Previously, it was used in the field. The stove can be called an army stove, since it was often the military or geologists who made such devices.

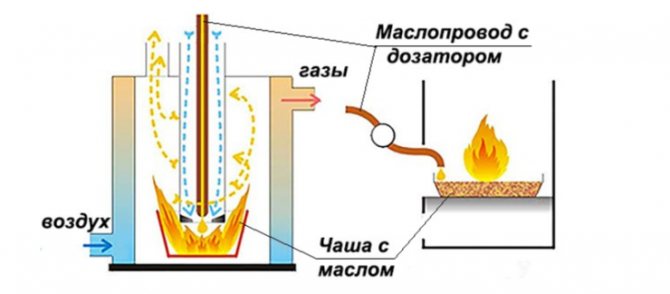

The operation of a stove for a greenhouse on diesel or other liquid fuel is based on the method of drip feed into the combustion chamber. To implement such a project, you can use an old gas cylinder or a large diameter pipe. At the bottom there is a small container, like a bowl, where diesel fuel will burn.

From above, to the very bowl, a perforated pipe is installed through which air enters. Due to this, the furnace turns out to be especially economical, since not only combustion of fuel vapors occurs, but also pyrolysis gases.

Inside the air supply pipe, a pipe is installed through which fuel is supplied. And the fuel tank itself is located at a distance from the main structure, which makes the installation safer. Fuel metering is interesting. Here an ordinary dropper finds its application, and the flow is regulated by a dispenser from it.

Such a furnace can work not only on diesel fuel, but also on working off

It will not be superfluous to make two more holes, one of which serves as a viewing window, and the second is intended for cleaning the unit from the inside. They will also act as an explosive valve when needed.

In order to increase the performance of such a heater, an adjustable fan can be added to blow air. This will provide not only better combustion, higher temperature and efficiency, but also the possibility of more accurate temperature control.

The resulting model of a homemade stove can operate both on diesel fuel and used oil.