What are

Heating devices are classified according to the following criteria:

- Coolant type. It can be liquid or gaseous.

- Manufacturing material.

- Specifications. This refers to the size, power, installation features and the presence of controlled heating.

When choosing the best option, it is necessary to build on the features of the home heating system and operating conditions. In this case, the entire list of requirements and standards regarding heating devices must be observed. Along with the power of the products, the specificity of their installation is of great importance. In the absence of gas supply and the possibility of arranging water heating, there is still an option with electric heaters.

Constant heating temperature of electrical appliances

Why does the heating temperature remain constant in all heaters?

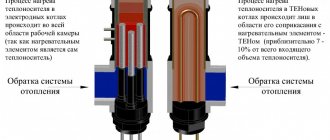

Heating of a conductor is related to electrical resistance. And the electrical resistance of the conductor depends on the temperature. The lower the conductor temperature, the lower the conductor resistance. If a conductor heats up, its resistance increases. The change in electrical resistance during heating leads to the fact that the same power is maintained all the time, which is released during heating in the conductor.

Heating elements are of particular importance today. In the near future, we can expect the appearance of heated sidewalks, heated streets, and not just the use of heating devices in the premises.

Water heating system device

Hot water heating is the most common way to heat buildings. This explains the availability on the market of a significant variety of varieties of heating devices for water circuits. The reasons lie in the good level of efficiency of these products, as well as the reasonable costs of purchasing, installing and operating the service. The designs of these heating devices are very similar to each other. The core of each of them is a cavity: hot water circulates through it, heating the surface of the battery. Further, the convection process comes into play, transmitting heat to the entire room.

Radiators for water heating systems can be made of the following materials:

- Cast iron.

- Become.

- Aluminum.

- Combinations of materials (so-called "bimetallic batteries").

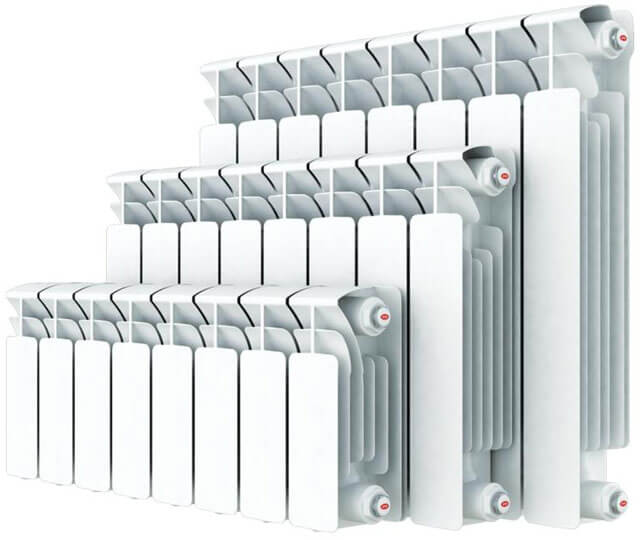

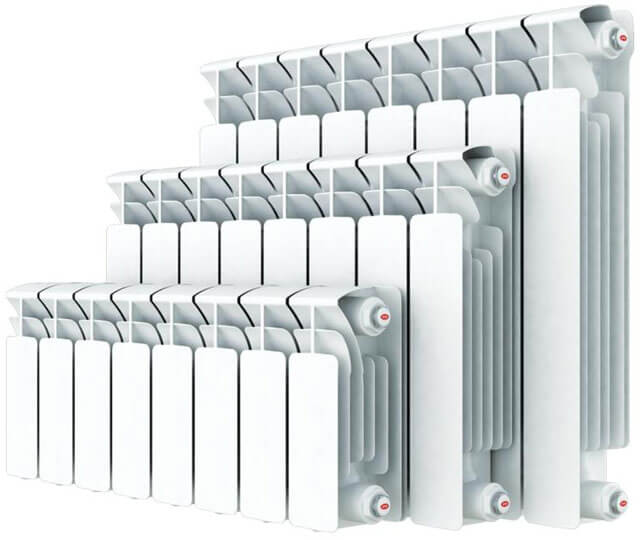

Any of these types of heating devices has its own specifics. In each specific case, it is necessary to take into account the area of the heated room, the installation features, the quality and type of heat carrier used (for example, in some cases, antifreeze is used). To regulate the power of the batteries, it is possible to add or detach sections. It is desirable that the length of one radiator does not exceed 1.5-2 meters.

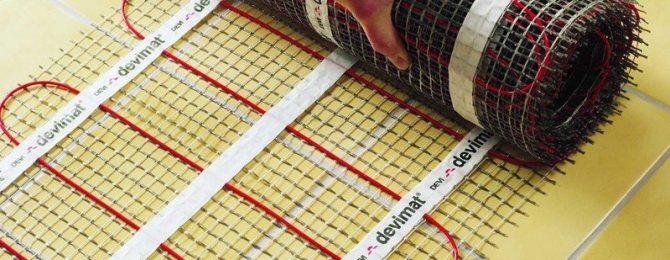

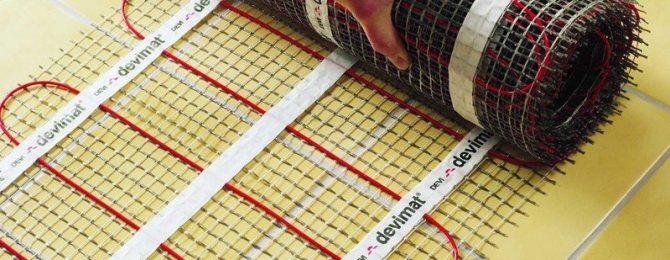

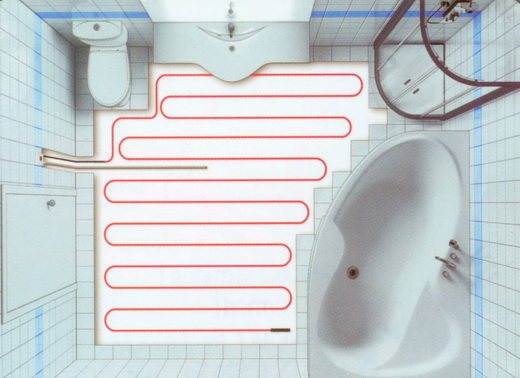

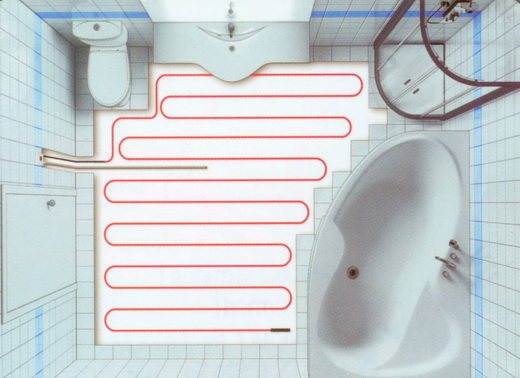

Warm electric floors

This type of heating is already perfect for an apartment building. Here you can use a heating cable, which will be stretched throughout the room and will heat it. There is also an option for heating with heating mats. This design consists of a thin cable and fiberglass; of the pluses, it is worth noting the unimportance of the screed. Infrared film can also be used, but we have already talked about it above. We recommend installing such a heating system in the bathroom, kitchen and hallway. This will keep the temperature of the floor and the room as a whole warm without spending too much energy.

Cast iron batteries

The cast-iron type of heating devices is one of the most common options for completing domestic centralized systems. It was preferred to other varieties mainly due to its cheapness. In the future, devices of this type began to be gradually replaced by devices with a higher heat transfer coefficient (for cast-iron batteries, it is only 40%). Currently, cast iron radiators are mainly equipped with old-style systems. As for modern interiors, you can find designer cast-iron models in them.

The strengths of the device of heating devices include a significant surface area through which energy is transferred from the coolant to the surrounding space. Another noticeable advantage is the durability of cast iron batteries: they can serve without problems for 50 years or more. There are also disadvantages, and there are many of them. Firstly, the coolant is used in very large volumes (up to 1.5 liters for each section). Cast iron is heated slowly, so you have to wait until after turning on the boiler heat begins to flow into the rooms. These batteries are not easy to repair and have to be cleaned every 2-3 years to minimize the likelihood of breakdowns. Installation work is complicated by the large weight of the radiators.

Radiators

Cast iron radiators.

Cast iron has a high thermal conductivity. For these reasons, heating devices made from it can be used in systems with large pressure drops and poor water preparation (increased aggressiveness, pollution, pieces of scale). Just all these qualities are possessed by one-pipe systems prevailing in multi-storey construction.

Cast iron radiators have been produced for over 100 years. This is a kind of classic, on which more than one generation of our fellow citizens was "brought up", who usually called this heating device a battery. Until the 1960s, almost the entire range of heating devices in our country was formed from batteries. And today this heating device, prematurely written off by many, still retains up to 70% of the Russian market.

Modern heating radiators have good design and high heat dissipation.

In our country, cast iron radiators are most often used, consisting of two-channel sections connected to each other. The number of sections is determined by the calculated heating surface. They also use single-channel, and abroad multi-channel (up to 9 channels in one section) cast iron radiators.

Their disadvantages include a large weight, a significant percentage of factory rejects - cracks and cavities that form as a result of poor-quality casting and reduce a potentially very long service life. According to the regulations, the warranty period for radiators is 2.5 years from the date the object is put into operation or sold within the warranty storage period, and manufacturers and sellers promise at least several decades of flawless service for these devices. Sometimes cast-iron radiators are reproached for the lack of an attractive appearance (remember: "accordion battery"). However, the use of modern designs and powder paints can add charm to these veterans too.

Systems in which cast-iron radiators are involved, due to the high thermal inertia, are not easy to regulate. Although there is a way out of this situation, and in some models, by reducing the capacity of the sections, it is possible to effectively use thermostatic elements (such as, for example, Danfoss RTD-G, RTD-N thermostats).

Domestic products prevail in this class of heating devices. Among the foreign ones, one can single out the cast-iron sectional radiators of firms Roca (Spain), Viadrus (Czech Republic), Biasi (Italy), "Santekhlit" (Belarus), Turkish radiators Ridem.

Steel panel radiators

Formed from two stamped sheets. In our country, their production began in the 1960s. They are distinguished from sectional cast iron ones by their lower weight (specific gravity per 1 kW is about three times lower) and thermal inertia. They are considered "sissies" because they are more sensitive to hydraulic shocks that occur when the system is stopped or started and are afraid of corrosion provoked by frequent drains or a high oxygen content in the coolant. In systems where there are multiple pressure surges "above the ordinary", it is not necessary to rely on a long service life of steel panel radiators.

Typically, the operating pressure of devices of this type does not exceed 9 atm.

expert opinion

V.V. Kotkov Commercial Director of the Group

It can be argued that the share of progressive (in relation to the so far prevailing classical cast iron) radiator designs is increasing. Today in Europe, up to 5 million sections of aluminum radiators are produced annually. To a large extent, the development of this production is stimulated by the Russian market, where the demand for them is annually increasing by 5-10%. Therefore, leading Western companies are trying to adapt their products as much as possible to Russian conditions (existing problems with water treatment in our country, high unstable pressure in central heating systems, etc.). Although, by tradition, many Russian construction companies give priority to cast iron radiators, the number of companies working with aluminum is steadily increasing. After all, an aluminum radiator is not just a private technical solution, but a solution to a whole range of problems related to efficiency, safety and design. It is able to fit into a modern interior, it does not need to be masked, spending a lot of money on it.

Steel panel radiators are widely used in low-rise construction. They are especially appropriate for a two-pipe heating system, which is preferred in cottage construction. In multi-storey buildings, it is reasonable to install them in the presence of an individual heating point, that is, a boiler room. Three quarters of steel panel radiator sales are from private developers, luxury housing and civilian buildings. The most famous models of firms in our country are: VSZ (Slovakia), Dia Norm, Preussag, Kermi (Germany), Korado (Czech Republic), DeLonghi (Italy), Stelrad (Holland), Purmo (Poland), Roca (Spain), DemirDokum (Turkey), Impulse west (England, but assembled in Italy), Dunaferr (Hungary).

Tubular and sectional

The radiators are outwardly similar, although they are structurally different - in the tubular sections, as such, they are absent, and the tubes are connected by two monolithic collectors. Both have an attractive appearance and fit organically into almost any interior. The streamlined form of the radiator eliminates the possibility of human injury. The small capacity of the sections contributes to effective thermoregulation. And if some of its elements are made of a finned tube, then it is possible, without changing the linear dimensions, to significantly increase the power of the radiator.

The working pressure of tubular steel radiators is higher than that of panel radiators - 10 and more atm.

In our market, this type of radiator is represented mainly by German brands. Bemm, Arbonia, Kermi.

Aluminum

They call radiators made from an alloy of aluminum with silicon (the content of aluminum itself is from 80 to 98%). Aluminum is a material with high thermal conductivity, but it imposes increased requirements on the chemical composition of the coolant. The disadvantage of radiators made of an aluminum-silicon alloy with a high silicon content is the generation of hydrogen in contact with water. The excellent design performance of most radiators somewhat spoils the automatic air release valve installed on each device, since hydrogen is actively evolved during operation.

A significant part of the Russian market for aluminum radiators is occupied by products of Italian firms: Rovall, Industrie Pasotti, Global, Alugas, Aural, Fondital, Giacomini, Nova Florida... There are also Spanish radiators Roca, Czech Radus, English Wester, etc.

Bimetallic radiators

Outwardly similar to aluminum. The sections consist of two thin-walled steel pipes (channels for the passage of the heating medium), pressed under pressure with a high-quality aluminum alloy. The logic of this symbiosis is based on the fact that aluminum has a high thermal conductivity, and steel has strength, which guarantees the operation of the device at excess pressure. Italian firms are the actual monopolists in the production of bimetallic radiators. The most famous trade mark is Sira.

Bimetallic radiators are both durable and efficient.

Convectors

The basis of the convector's design is a heating element enclosed in a casing. Flowing to it from below, the cooled room air heats up and rises. As a result, more than 90% of the heat is transferred by convection.

Convectors are most widely used in autonomous systems. They are especially effective at low coolant temperatures. So, they are able to warm up the room at a water temperature of only 40 ° C. For the convenience of the user, the convector is equipped with an air valve and a drain pipe. The built-in thermostat and water pressure regulator make it economical to operate.

The convector fits especially harmoniously into the modern architectural environment, which actively uses large windows, bay windows, winter gardens, etc.

Structurally, it can have four solutions:

- Radiator convectors are a combination of two devices, reflected in the name itself. They are installed near windows, on the floor or on small stands.

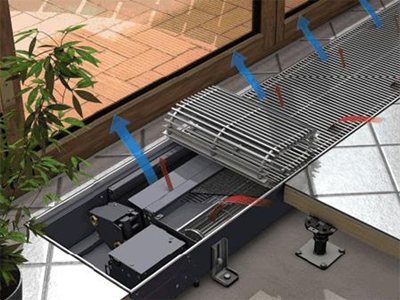

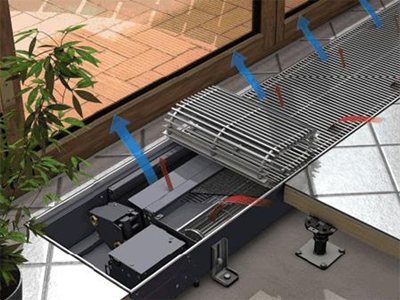

- Convectors buried in the floor are the best option for living quarters on the ground floors. The device is placed in a kind of shaft, cold air passing along the window freely enters the convector, and the flow of warm air ensures natural circulation in the room.

- Convectors covered with a decorative screen. Unlike radiators, a closed convector does not lose in heat transfer at all, on the contrary, the screen increases traction.

Skirting convectors are located in the floor under large windows. The low height (90–100 mm) does not require niches, and the weak convective flow can be enhanced by a slowly rotating fan.

Bimetallic batteries

The strong point of bimetallic structures is special convection panels that increase the quality of air circulation. In addition, devices of this type can be equipped with special regulators, with which you can increase or decrease the flow rate of the coolant. Installation work in its simplicity resembles the installation of aluminum radiators. Each of the sections has a power of 180 W, providing heating for 1.5 m2 of area.

In some cases, the use of water-type heating appliances is encountered with serious difficulties. For example, bimetallic radiators cannot be installed in systems where antifreeze is used as a coolant. These non-freezing liquids, which protect pipes from freezing, can have a destructive effect on the inside of the batteries. You should also take into account the high cost of this heating option.

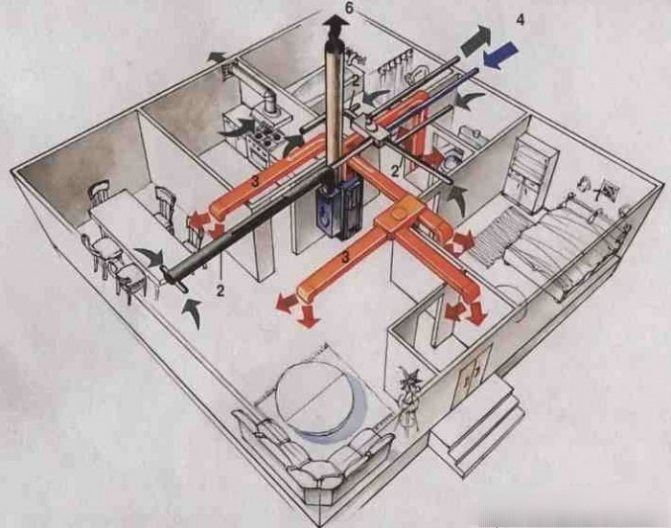

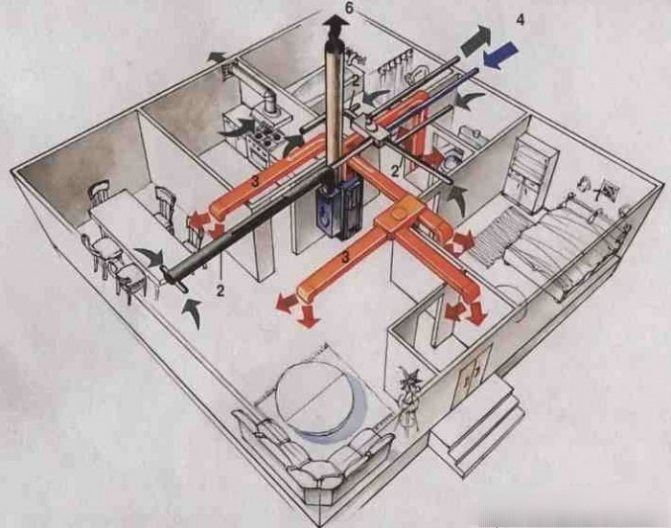

Air heating

These types of heating of various premises are considered one of the oldest. For the first time such a system was used even before our era. To date, such a heating system has become widespread - both in public premises and in production.

Air heating of a private house

Heated air is also popular for heating buildings. In recirculation, this air can be supplied to the room, where it mixes with the indoor air and thus the air is cooled down to the room temperature and reheated.

Air heating can be of a local nature if the building does not have central ventilation, or if the amount of air supplied is less than necessary.

In air heating systems, air is heated by air heaters. The primary heater for such components is hot steam or water. In order to warm up the air in the room, you can use other heating devices or any heat sources.

Local air heating

When asked what kind of heating is, local heating is often equated only to production premises. Local heating devices are used for such premises that are used only during certain periods, in premises of an auxiliary nature, in premises that communicate with external air currents.

The main devices of the local heating system are the fan and the heater. For air heating, devices and devices such as: air heating devices, heat fans or heat guns can be used. Such devices work on the principle of air recirculation.

Heat gun

Central air heating

Central air heating is done in rooms of any plan, if the building has a central ventilation system. These types of heating systems can be organized according to three different schemes: with direct-flow recirculation, with partial or full recirculation. Full air recirculation can be used mainly during non-working hours for on-duty types of heating, or to heat the room before the start of the working day.

Central air heating

However, heating according to such a scheme can take place if it does not contradict any fire safety rules or basic hygiene requirements. For such a heating scheme, a supply ventilation system should be used, but the air will not be taken from the street, but from those rooms that are heated. In the central air heating system, such constructive types of heating devices are used as: radiators, fans, filters, air ducts and other devices.

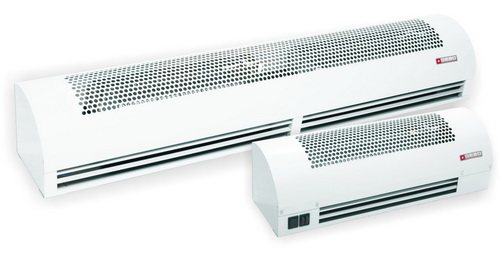

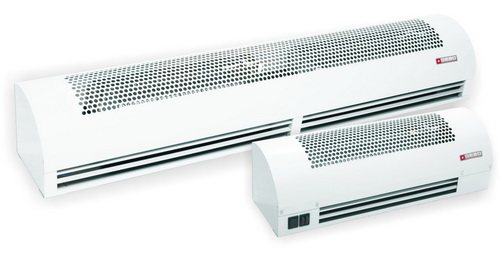

Air curtains

Cold air can come in large quantities from the street if the front doors of the house are opened too often. If nothing is done to limit the amount of cold air that enters the room, or not to heat it, then it can adversely affect the temperature regime, which must comply with the norm. To prevent this problem, you can create an air curtain in an open doorway.

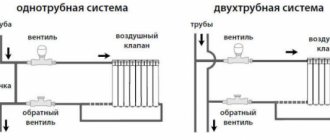

Types of hot water heating

In the entrances of residential or office buildings, you can install a low-height air-thermal curtain.

Limiting the amount of incoming cold air outside the building takes place due to a structural change in the entrance to the room.

Electric air curtains

Air-thermal curtains of compact type have become more and more popular recently. The most effective curtains are considered to be the "chibber" type. Such curtains create a jet air barrier that will protect the open doorway from the penetration of cold air currents. As a comparison of heating types shows, such a curtain can reduce heat losses by almost half.

Electric types of heaters

In cases where problems arise with the organization of water heating, it is customary to use electric heaters. They are also presented in several varieties, differing from each other in power and method of heat transfer. The most significant disadvantage of household heating appliances of this kind is the high cost of consumed electricity.In this case, it is often necessary to lay new wiring, designed for increased loads. If the total power of all electric heaters exceeds 12 kW, technical standards provide for the organization of a network with a voltage of 380 V.

Hot water pipes

The functioning of heating devices in hydraulic systems is impossible without pipes. The first polymer (PVC) pipes were manufactured in 1936 in Germany. The first pipeline of them was built in the same place in 1939. But the active introduction of polymer pipes into water supply and heating systems began in the mid-1950s, and in our country from the early 1970s.

Both for systems using classic radiators and for underfloor heating, XLPE pipes are best suited. They are not afraid of short-term temperature increases up to +110 ° C (normal operating temperature is usually +95 ° C). With all the advantages, they have one drawback - the high price.

Used in heating systems and propylene pipes... But at the same time, the high coefficient of thermal expansion of the material should be taken into account. The service life of polymer pipes can reach 30 years or more. The gasket must be hidden: they are hidden in baseboards, shafts, channels or in floor structures. If polymer pipes are used in heating systems, then in order to protect them from exceeding the parameters of the coolant, it is necessary to provide for the installation of automatic control devices.

The advantages of plastic and metal pipes combine metal-plastic pipes. They are combined with other materials, do not allow oxygen to pass through, and due to their smooth inner surface, their resistance to flow is less than that of steel, which in conditions of mass use allows you to save a lot of energy. The warranty period is at least 20 years, but, as a rule, in reality it reaches 30-50 years. For comparison, according to the State Construction Committee of the Russian Federation, galvanized steel pipes in internal systems serve an average of 12-16 years, and "black" - half as long.

Competing devices for hot water heating systems

| Heating appliance type | Stamps | Price for a conventional unit of equipment with a capacity of 1 kW (in euros) |

| Steel tubular radiator | Arbonia Kermi "TERMO-RS", "BITERMO-RS" | 100–160 80 |

| Copper-aluminum radiator (Belgium, Russia) | JAGA, "Isotherm" | 100 |

| Bimetallic radiator (Russia, Czech Republic) | SIRA, Style, Bimex | 85–95 |

| Cast aluminum radiator (Italy) | Elegance, Nova Florida, Calidor Super, Sahara Plus, Global MIX, Global VOX | 64–75 |

| Extrusion aluminum radiator (Italy, Russia) | Opera RN ("Stupinsky radiator") | 63 50 |

| Steel panel radiator | Kermi, Korado, DeLongi, Stelrad | 50 |

| Convector (Russia) | "TB Universal" | 25 |

| Cast iron radiator | MS-140 Demir Dokum, Roca | 25 65 |

Oil radiators

The principle of convection is also used in the operation of oil electric heaters. Special oil is poured into the apparatus for heating with a heating element. To control heating, a thermostat is often used, which turns off the power when the desired temperature mark is reached. Oil-powered devices are characterized by high inertia. This is manifested in a slow warming up of the device and in the same slow cooling down after a power outage.

The surface temperature usually heats up to 110-150 degrees, which provides for the observance of safety rules. Such a device must not be installed close to flammable surfaces. Oil radiators are equipped with convenient regulation of the heating intensity, designed for 2-4 operating modes. Keeping in mind the power of one section (150–250 kW), it is not at all difficult to choose the optimal model for heating a particular room. The maximum power of such a device is limited to 4.5 kW.

Heating with underfloor heating

This type of heating creates a high level of comfort by heating the floor, but not to the temperatures of conventional radiators. It should also be taken into account that the room heats up evenly.Such heating quickly heats up the room, which means it has high inertia. Using this heating, you can safely ventilate the room, while you will not feel the cold, it also increases the space in the house compared to conventional radiators. But it should be borne in mind that the house must be well heated and that some difficulties may arise during installation in an apartment. It is also a rather expensive type of heating (more expensive than radiator), although they say that it will soon pay off by saving electricity. But even in a cold winter, it will be difficult for you to use this type of heating, since you cannot raise the floor temperature to a very high one, you still have to use radiator heating additionally in a harsh winter.

Infrared heating

The choice of infrared heaters brings the following dividends:

- Energy savings of up to 30% when compared with conventional electrical appliances.

- Oxygen in the air does not burn.

- The room heats up in a matter of minutes.

Infrared devices are classified according to the method of wave transmission. In new heating devices, radiation is transmitted to the surrounding space thanks to resistor conductors installed on a special film. The power of warm mats can reach 800 W / m2. Film heaters are convenient because they can be used to organize warm floors.

As for carbon emitters, waves are emitted in them in spirals from a sealed transparent bulb. The power of such devices is in the range of 0.7-4.0 kW. The power of carbon heaters is an order of magnitude higher, which provides for more stringent fire safety measures.

Purpose of radiators and heating batteries

Air heating in a wooden house is carried out due to the release and transfer of heat to the premises by heating radiators. Such devices differ among themselves not only in design features, but also in the method of heat transfer and design. Despite some differences, heating devices can be divided into classes according to the following criteria:

- The heat carrier used in the system is hot water or antifreeze, heating with gas or electricity.

- The material used for the manufacture of radiators. It can be cast iron, steel or a compound of polymers with metal, the so-called bimetallic structure. Such devices are installed in a closed heating system.

- Performance classification. This includes the power of the device, overall dimensions, and the availability of additional equipment (the ability to adjust the degree of heating).

Note! The choice of a specific type will depend on the heat supply system used, for example, bimetallic batteries can be used in both water and steam heating.

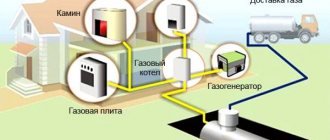

Gas heating

In order to save money, you can use gas heaters. Their simplest type is a gas convector, which is switched to a main gas pipeline or a LPG cylinder. The burner of the device is completely protected from contact with the surrounding atmosphere: in this case, a special tube is used to supply oxygen, which is led out into the street through a hole in the wall. These devices are characterized by high power (at least 8 kW) and low cost of operation. Among the weaknesses of gas heaters, one can single out the obligation to register with regulatory agencies, the need for effective ventilation and the need for regular cleaning of the nozzles.