Natural wood is highly valued in construction, furniture production and other areas of the national economy. After processing, even waste is used. One of the directions is the pressing of sawdust, as a result of which briquettes are formed, which have a longer burning period than firewood and other types of solid fuels.

The design of the presses differs slightly depending on the type; in general, it is a mechanical device with a base, a power frame and a drive. The principle of operation is to compact raw materials and form briquettes, fillers for pet trays.

The process of preparing sawdust deserves special attention. They are pre-sorted, dried and crushed. This helps to produce better quality products. In addition to sawdust, briquettes may include waste paper, nut shells and sunflower seed husks.

Before deciding to buy a press, it is worthwhile to understand the appropriateness of its use. The equipment justifies the costs in the presence of available raw materials and a solid fuel boiler (or product market).

Among the advantageous characteristics of the presses:

- rational use of wood waste (for heating rooms, greenhouses, utility rooms, ash is used as fertilizer);

- understandable and accessible production process;

- simple and reliable device (hydraulic models practically do not have units of increased wear);

- maintenance does not require knowledge of complex technologies.

The disadvantages include:

- the use of equipment provides for the preparation of raw materials;

- rapid wear of units in the screw extruder;

- in some types, the addition of binders is provided.

Types of presses

There are 4 types of presses used for processing sawdust. The differences between the devices are noted in the principle of operation and cost.

The requirements for the preparation of raw materials are the same:

- uniform grinding to obtain fractions of no more than 25x25x2 mm;

- humidity level within 4-10%.

Each model has both advantages and disadvantages, therefore, before choosing, you should carefully read the technical characteristics:

- The mechanical impact press, according to the principle of operation, resembles a hammer drill, where the crank mechanism transmits a series of shocks to the piston with a frequency of 20 times per second. The blows provoke the pushing of the sawdust through the die. The equipment copes with pressing not only wood waste, but also a mixture of coal dust, straw, peat, residues after MDF processing. The main advantage of the press is long-term functioning without human intervention. High productivity is also noted. The crank nodes are a vulnerable spot, which is due to the effect on them simultaneously of 2 forces: shock and friction.

- The hydraulic press is a two-piece device (mold, cylinder). According to the principle of operation, the equipment resembles the action of a jack, where a hydraulic cylinder exerts pressure with a piston on a mold filled with prepared raw materials. The result is a molded briquette. The equipment is considered simple and reliable to use, there are practically no wear units. Pricing policy Models of this type are competitive. The downside is poor performance. There is also a nuance in the production process - a binder is added to the prepared sawdust.

- The screw press (extruder) is similar in principle to a meat grinder. The crushed and dried sawdust is fed through the auger through the die, as a result of which the mass is compressed and pressed under high pressure. The process involves exposure to high temperatures, without which the equipment can jam. The hot stream provokes the release of lignin (a natural binder) from the wood, which holds small raw materials together and is the key to high-quality molding. The screw device is considered the leader in performance, the production process is carried out continuously. Of the shortcomings, the need for heating is noted, which makes the preparation procedure lengthy. You also need to take into account that the finished product has a lower calorie content due to exposure to high temperatures (above 120 ° C). Units such as auger and die are quickly worn out due to increased friction during operation.

- A pellet mill is similar in principle to a feed pellet mill, only sawdust is used instead of grain crops. Compared to other types of equipment, it has the simplest device, but at the same time it has good performance and an affordable price policy. The press is equipped with various devices to improve the quality of the product. These are: a mixer for mixing raw materials, a humidifier for over-dried workpieces, various cutting attachments that change the shape of the briquettes. The manufacturing process involves the use of an additional binder to increase the density. Of the minuses, the need to grind the raw material during preparation to the finest fraction is noted. On such equipment it will be possible to produce only small briquettes.

Each model has both advantages and disadvantages, therefore, before choosing, you should carefully read the technical characteristics.

Home technique

Of course, purchasing powerful professional equipment for home use doesn't make sense. The cost of such a unit will pay off only if pressed firewood is produced for sale. Unfortunately, it will not work to adhere to the standard technology that releases lignin. We recommend: Wood chipper: DIY chipper

You can replace woodworking waste with tree branches after winter pruning.

Before pressing, they must be crushed with a crusher. You can also use materials that burn well, such as straw, paper, seed husks.

Home craftsmen figured out how to form briquettes without a natural binder. Instead of lignin, they often use:

- Clay.

- Wallpaper glue.

- Paper and cardboard.

Craftsmen were able to get around the lack of a briquetting press for sawdust... Raw materials are soaked in water and then mixed in clay. In this case, it is important to adhere to the proportion of 1:10. If there is no clay, add soggy paper or glue. The prepared material is sent to a homemade briquetting unit and pressed by hand. The resulting briquettes are removed from the press and sent to dry in fresh air.

Equipment selection

When choosing a sawdust press, important factors should be considered:

- the purpose of the equipment;

- what kind of raw materials it works for;

- type of briquettes produced;

- device power;

- planned volume of finished product output;

- completing with other equipment to obtain a high quality product;

- functionality of the selected model;

- operating mode of the unit and features of its maintenance.

You also need to pay attention to the components that are subject to wear. Frequent repairs and their cost will help determine the rationality of buying a particular model.

When choosing a press for personal use, you should remember that the equipment should be simple with options for setting parameters.If the products are not planned to be put up for sale, then it is enough to purchase only one unit. To reduce the cost of purchase, you can take advantage of interesting offers for the sale of used devices.

When choosing a press for personal use, you should remember that the equipment should be simple with options for setting parameters.

Do it yourself

The high cost of equipment does not always justify the cost of purchasing it, so craftsmen embody their developments to create homemade presses. It is worth noting that it is quite difficult to make a screw device, therefore, not everyone is taken for this type of pressing.

At home, it is almost impossible to achieve the required pressure level that would ensure the release of lignin. But it is quite possible to build hydraulic units and granulators with your own hands.

All homemade devices are divided into three main types:

- The technology of sawdust briquetting itself is quite interesting and has its own advantages, so the owners do not deny themselves the desire to acquire a home press

from jacks;

- with manual drive;

- with hydraulic drive.

The technology of sawdust briquetting itself is quite interesting and has its own advantages, so the owners do not deny themselves the desire to acquire a home press.

Thanks to the use of briquettes, it is possible to prevent the formation of debris at the furnace or boiler furnace, as well as to exclude frequent loads. The location of self-made units can be wall and floor, it is already as convenient for someone.

Before proceeding with the assembly of the press, it is necessary to take into account all stages of the production process to ensure the drying and crushing of the raw materials. It is also worth taking care of a utility room or a shed for storing finished products.

To assemble a hydraulic press, you will need to prepare the following materials and tools:

- metal sheet 4-6 mm;

- corner 100x100 mm;

- channel;

- a pipe with thick walls (the diameter is determined by the dimensions of the briquettes at the outlet);

- pipe 25-30 mm for the manufacture of the punch rod;

- galvanized steel for forming trays;

- large pipe or sheet of metal for the manufacture of the mixer body;

- welding machine and electrodes;

- grinder with discs;

- drill;

- a hammer;

- measuring devices, etc.

DIY press for making fuel briquettes

The purchase of finished equipment for the production of briquettes, depending on its capacity, will cost from 300 thousand to 1 million rubles.

Of course, for a private trader who wants to start manufacturing this fuel purely for their own needs, such costs are inexpedient, since they will not pay off soon. It would be more correct to make a press from scrap materials, especially since there is nothing complicated in its design.

You can build the necessary equipment from scratch or use ready-made mechanisms.

Homemade machine

Installation from scratch

You can create a significant force required to compress the raw material using:

- a lever (it can be influenced by its own weight);

- screw mechanism.

A lever press can even be made of wood; for a screw press, you will definitely need steel blanks and a lathe.

A screw extruder (sawdust press) can theoretically also be made by hand and some craftsmen even succeeded, but such an undertaking is costly due to the complex processing of parts and the need to use special high-quality steel is very expensive.

Pellet heating is not only economical, but also environmentally friendly, because recyclable materials are used as fuel. You can make a pellet boiler with your own hands or alter a solid fuel boiler for pellets.

You can find detailed instructions for making a solid fuel boiler with your own hands here.

Doubting about choosing a pellet boiler? Follow this link: you will find feedback from real users about these boilers. Read and draw conclusions.

Production of a press on the basis of a ready-made mechanism

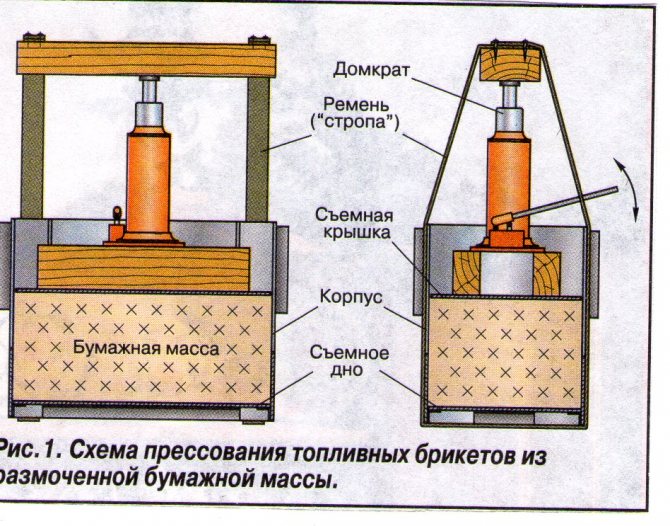

For the production of briquettes, you can adapt some more affordable device than a real machine, a device - a jack or a small hydraulic press. It only remains to supply it with a punch and a die.

It should be understood that any home-made press, even one based on a hydraulic jack, will not be able to develop the forces that ensure the release of lignin. Therefore, instead of it, third-party binders have to be added to the raw materials.

In this capacity, they are used:

- Cheap glue such as wallpaper.

- Clay (add 1 part to 10 parts of sawdust).

- Damp paper, including corrugated cardboard - the lignin contained in it, upon contact with moisture, exhibits its sticky properties (this property of paper is used when spraying a heat insulator of the Ekovata type).

Another difference from industrial technology is that the starting material is not dried, but rather soaked in water - then the particles stick together better. Then the finished briquette is dried in the open air.

How to grind raw materials

For the hassle of making a homemade press, one should not forget about such an important stage in the production of briquettes, as the grinding of raw materials. Cutting it by hand is very difficult - mechanization is also necessary here. Some make shredders on their own from an old activator washing machine - they install knives instead of an activator.

Another option is to purchase a rotary machine. The purpose of this device is precisely the crushing of vegetation - summer residents use it to make fertilizers from leaves and grass.

The structure is made on the basis of a hydraulic installation

Step-by-step instructions for making a press

- To make the base, you need to connect the parts from the channel by welding.

- Cut 4 pieces 1.5 m long from the corners (they are used as racks). Weld them to the base at the same distance from each other (vertical arrangement).

- Fix a drum made of a large-diameter pipe to the corners. If such a pipe is not at hand, you can make a mixer body from a sheet of tin. To increase productivity, it is equipped with an electric motor.

- A box for filling raw materials is made of sheet iron. It is recommended to make the shape of the body in the form of a cone for the spontaneous movement of the loading when filling the trays.

- The gearbox is fixed to the bottom of the cone-shaped body. and weld the output tray.

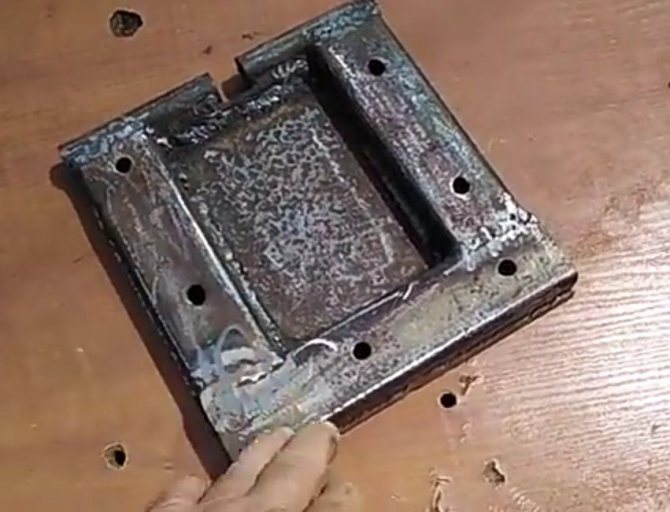

- In a pipe with thick walls, make holes at intervals of 3-5 mm. During the pressure on the mass, air and water will escape through the holes. Weld a flange to the bottom of the workpiece, which will hold the removable bottom. The bottom is made of steel sheet in the form of a circle with lugs.

- Weld the matrix to the base under the cone-shaped body.

- Cut a disc of this size from sheet steel, which would allow you to move freely in the matrix. It functions as a punch.

- Weld the prepared tube for the stem to the punch. The other edge is attached to the hydraulic unit.

- The assembled unit is attached to the racks directly above the matrix.

- The receiving tray is installed in such a way that it does not interfere with the shooting process and fixing the matrix bottom.

Preliminary drying will be provided by heating elements installed along the perimeter of the machine. The briquettes will be able to take final readiness in an open area with a low air humidity.

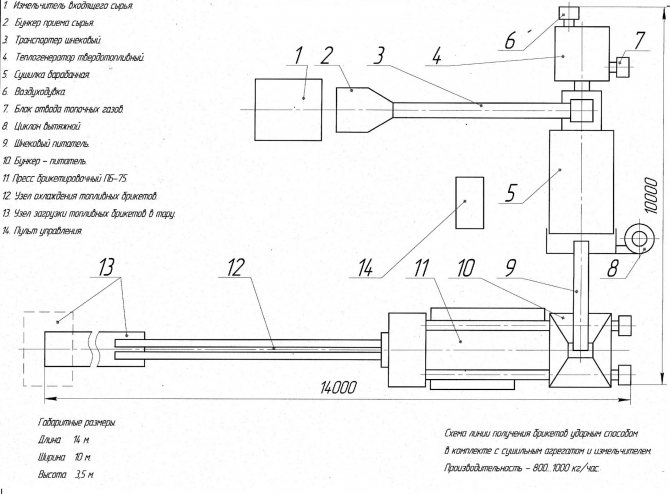

According to the technological process, the raw materials need to be prepared before processing, which means that a dryer and a device for grinding will be required.

Homemade or store-bought

The purchase of a press is justified in cases when production adjustment is planned. There is no need to purchase equipment for the production of briquettes, which will subsequently be used only for household needs. In addition, the cost of the units is high, not everyone can afford it. And the installation provides for a separate room.

According to the technological process, the raw materials need to be prepared before processing, which means that a dryer and a device for grinding will be required. In addition, the finished briquettes after production must be stored in a dry room, which simply may not be available.

Handicraft production will not produce a quality product, briquettes will have insufficient density, and this reduces the specific heat of combustion. Having weighed all the factors, we can summarize that there is no point in purchasing expensive equipment.

If a solid fuel boiler is installed in the house, you can build a press with your own hands. This will require available materials, as well as familiarization with the design diagrams in order to choose the appropriate option.

The advantages of using ready-made presses for production purposes:

- simple arrangement of equipment;

- the ability to replace worn out units;

- selection of models of different capacities and performance;

- the technological process does not require special knowledge and skills;

- you can equip the workshop in a small room.

When deciding to start production, it is worth considering important factors:

- type of raw material, its availability;

- the approximate volume of processing for a certain period of time;

- required areas;

- the scheme for the sale of finished products.

For large-scale production, it is recommended to purchase automatic and semi-automatic equipment. The units are distinguished by high efficiency and wear resistance of working units.

The production of fillers for animal trays can be put on stream using granulators. The diameter of the product just meets the standards, and a high density is not required.

What is more profitable - firewood or briquettes?

Since the price is one of the most exciting characteristics for the end consumer, the review should start with it. 1 m3 of fuel in briquettes costs about 2 times more than firewood. However, the cost can vary even more depending on the quality of the pressed sawdust and the type of wood in the logs. Throughout the analysis, the average values for both types of solid fuel will be compared.

Eurowood burns 2 times longer, respectively, their mass consumption is much lower. So far, it turns out that economically there is no difference - they cost 2 times more and serve 2 times more.

Fuel briquettes give a uniform calm flame throughout the entire period of time, with firewood everything is different, at first they flare up with a large beautiful fire, emitting a large amount of heat, then it goes out, and a person sees coals with rare tongues of flame. From this we can conclude that pressed fuel is better suited for heating, it gives constant stable heat. The advantages of firewood are faster heating and a visually more pleasant fire, especially at the beginning of use.

At the end of the furnace, a lot of coal and ash remain from the wood in the stove, and the euro wood burns out almost completely. Convenience of maintenance of heating equipment for fuel briquettes is much higher.

Among the compressed sawdust sold on the market, a significant share does not meet high quality standards, has a density lower than expected and is too easy to crumble. But even for firewood, everything strongly depends on the supplier, often they are shipped to the buyer raw, with a moisture content of up to 50%, and from another type of wood. One - one, low-quality goods can be bought here and there with approximately equal probability.

The comfort when using briquettes is definitely higher.No need to chop, dry wood. When storing eurowood, they take up much less space and can bring in more fuel at a time.

With all that said, fuel briquettes really turn out to be a little more profitable than their natural counterparts. This is especially evident in heating systems with heat carriers and automatic fuel supply to the combustion chamber.

Blitz Tips

- When making a homemade screw extruder only high quality steel should be used.

- It will not be possible to reproduce the process of producing briquettes with the release of lignin on home-made equipment, therefore, it is recommended to add clay, cheap wallpaper glue or corrugated cardboard to the crushed raw materials. These components will be used as a binder.

- The simplest and most affordable are considered to be hand-made devices equipped with a manual screw drive. The perforated form is filled with prepared sawdust mixed with a binder. Forming is carried out by tightening the screw. Such a press has one significant drawback - low productivity.

- Some craftsmen use a hydraulic jack to assemble a home press. It should be noted that such a device is not capable of creating a pressure of even 300 bar. A small amount of water and a binder added to the crushed raw material will help to improve the quality of the briquettes.

- Crushed sawdust is used for the press, so the equipment should be supplemented with a rotary machine, where you can prepare raw materials for pressing. You can also make a shredder with your own hands from an old washing machine. To do this, it is enough to install knives instead of the activator.

Making briquettes with your own hands

In the production of sawdust briquettes on an industrial scale, the natural adhesive material lignin is released from them, which acts as a glue and makes the product a monolith. At home, it is impossible to achieve such a density with improvised means with improvised devices, and therefore additional components must be added during pressing. These popular binders include:

- wallpaper glue;

- manure;

- clay.

The moisture content of the original wood should be below 12%, and the amount of damaged and unusable sawdust should be 5%.

Selection of raw materials and its preparation

To create such a compressed fuel with your own hands, you should choose a quality material. The basic ones are:

- sawdust;

- shavings after processing crops;

- waste paper;

- straw;

- secondary raw materials from coal and peat.

The total share of wood chips when choosing a combined composition of raw materials should not be less than 60%. In this case, high quality of briquette combustion is ensured.

Homemade pressing machines

Handcrafted sawdust machines can be roughly divided into the following types:

- manual;

- based on jacks;

- hydraulic.

In order to achieve the production of lignin, devices based on a lifting mechanism (hydraulic or screw type) can be used. Their main disadvantage is low productivity.

In addition to the jack, which performs the function of a press, a die and a punch are used in the machine. They give the finished wood a certain shape. A do-it-yourself screw extruder simplifies the task of producing pressed fuel, but it is also much more difficult to make it.

Stationary press to create fuel

You can make a briquette press if you have the following spare parts in stock:

- motor;

- bearings;

- reducer;

- shaft;

- screw;

- heating heating elements;

- relay for temperature control.

If the voltage consists of three phases, then a 9 kW motor is used, and if work is to be done from a standard 220 V network, then an engine with a power of 2.5 kW is needed. It, together with a gearbox and other units, is fixed on a welded frame.

In this installation, the auger is a special design of two components, one of which acts as a punch, and the other delivers sawdust to a specialized container for loading. The matrix is replaced by a profile tube.

Before starting a home-made machine, the pipe should be heated to 260 ° C, and the heating process of the heating elements is controlled using a relay. The disadvantage of this design is the large coefficient of heat loss to the air.

Briquettes manufacturing technology

The procedure for making briquettes with your own hands is divided into several sequential processes:

- Preparatory processes for raw materials and their purification.

- Grinding sawdust to a caliber of less than 0.6 cm.

- Pressing.

- Drying.

- Warehousing.

After the shavings have passed all the preparatory processes, they are mixed with clay powder in a 10: 1 ratio. Then the mass is stirred by adding a small amount of water. The mixture should be medium-thick to keep its shape.

It is discharged into a hopper for further briquetting. After all, it remains only to dry the finished firewood.

It is possible to artificially increase the combustibility of the pressed fuel by adding a little cardboard soaked in liquid to the clay.