The middle of the 90s of the last century was a turning point for the building materials market. Practical and inexpensive types of thermal insulation began to appear, for example, mineral wool, glass wool, cellulose-based insulation. These materials attract the attention of buyers with an affordable price and relatively good characteristics.

However, there are also significant disadvantages. In particular, these are rather bulky materials, and the thickness of the insulation slab "hides" the interior space of the premises. In addition, such thermal insulation can dry out and paint, which invariably leads to heat loss. Of course, mineral wool is still considered one of the most popular thermal insulation materials today.

However, this is not due to high efficiency, but to a democratic price. If there is a need for really high-quality thermal insulation of premises, penoizol is used during construction. This is a liquid insulation that is rapidly gaining popularity in our country.

What is this thermal insulation material?

Let's start with the definitions. The name "Penoizol" is a trademark of a heater based on urea resins. The material is in high demand, therefore it has become a household name, combining the following names:

- "Teploizol"

- "Mipora"

- "Unipor"

- "Mettemplast"

However, among professional builders, insulation is better known as liquid or jellied foam.

In appearance, the thermal insulation resembles a marshmallow, which, after hardening, turns into an elastic mass that is guaranteed to fill all the voids.

The composition of the insulation includes the following components:

- Urea resin

- Orthophosphoric acid

- Foaming additives

The ingredients are mixed in certain proportions and pumped into special cylinders, where the mixture is under pressure.

Why is penoizol so popular?

In search of quality insulation materials, many builders are looking for something that would be not only reliable, but also economical in terms of cost. As a rule, the use of penoizol is explained by the fact that it is good for them to insulate buildings with a wall thickness of about 10-20 mm, since this will reduce the cost of heating the house several times. And the cost of the work carried out on the insulation will pay off already during the first operation of the residential facility. Using urea foam to decorate interior wall openings or insulate the facade of a house, you can effectively protect it even in severe frosts. An important role is played by the cellular structure, which perfectly protects the interior from the penetration of noise.

Technical characteristics of urea formaldehyde foam (UF)

It is believed that in terms of the declared performance properties, penoizol surpasses any insulation available on the domestic market. The main characteristics of thermal insulation are as follows:

- Heat efficiency... The thermal conductivity of the insulation varies within 0.031-0.041 W / m on the Kelvin scale. It is enough to pour a layer of liquid foam into 10 cmto provide reliable insulation for the interior.

- Soundproofing... Penoizol absorbs up to 65% street noise, which is considered a very good indicator.

- Fire safety... The material is non-flammable and does not support combustion. However, when exposed to high temperatures, the insulation will simply evaporate without releasing toxic substances into the air.

- Dependence on chemical and biological factors... The insulation is neutral to any aggressive environment.In addition, the insulation is of no interest to rodents, it is resistant to pathogenic microflora: fungus, mold.

- Moisture resistance... The material absorbs moisture well, but subsequently evaporates it without losing its original properties. Considering this feature, it is recommended to equip ventilation gaps in order to prevent the formation of mold on the walls.

- Strength... The indicators of the linear compression of the insulation are 0.07-0.5 kg / cm2... Accordingly, the material holds its shape well, quickly restores the structure.

Manufacturers assure that thermal insulation can serve 30-50 years old without loss of quality. However, the insulation appeared on the market relatively recently, so there is no evidence of such an impressive service life yet.

Penoizol: what are the features?

As a rule, ecowool, polystyrene are most often used as insulation, but today penoizol is also becoming quite popular. It has many advantages, each of which plays a role in forming such a good opinion of the material. Firstly, penoizol is completely uninteresting to rodents and microorganisms, so you don't have to worry that the walls will gradually be eaten from the inside. It is noteworthy that if this material is mechanically affected, it will turn into dust. The second important point is that penoizol receives positive reviews due to its breathable structure and good thermal insulation properties. Due to the presence of capillary moisture transfer in the material, it can be safely used in wooden construction, while the appearance of mold is excluded. All excess moisture will be eliminated by the capillaries of the insulation. The third positive point is that compared to ecowool and glass wool, the material we describe is hermetic, it literally fills all the pores and details in its path.

Advantages and disadvantages of cured thermofoam

The popularity of penoizol did not arise out of nowhere. Among the indisputable advantages of insulation, the following features can be distinguished:

- High technical properties - even a layer of insulation in 45 mm, is able to prevent heat loss.

- Resistance to dynamic loads - the elastic structure allows you to recover to its original state even after prolonged compression.

- Neutrality to any external influences - sharp temperature changes do not affect the quality of the insulation.

- Excellent adhesion - due to the liquid structure, thermal insulation adheres well to any surfaces, fills all voids.

- Multifunctionality - insulation is suitable for any design, regardless of geometric shapes.

- Vapor permeability - when using penoisol, condensation does not form on the walls, which is very useful for wooden structures.

In addition, liquid foam does not form cold bridges.

Of course, there were some drawbacks. The weaknesses of the insulation are:

- Shrinkage - after pouring, the volume of the material may decrease by 0.1-5%.

- Moisture absorption - if we are talking about warming the foundation, this parameter can be regarded as a disadvantage.

- Dependence on temperature conditions - work with penoizol is possible only at an air temperature above +5 degrees.

- Low tensile strength - despite the elastic structure, the insulation is easily torn and pierced, which violates the thermal insulation performance.

The disadvantages include the high cost. Curiously, the price of insulation does not exceed the cost of mineral wool and other heat-insulating materials. However, pouring liquid foam requires special equipment that private developers do not have.

Therefore, the equipment has to be rented, or a team of builders must be hired, which makes the total cost of the work “heavier”.

The porous structure is the key to reliability

The studies carried out allowed us to bring together all the features that Penoizol has.Its characteristics are as follows:

- The resistance coefficient is 40% higher compared to mineral wool and cellulose insulation, which means that the level of heat loss will be minimal.

- Penoizol is not afraid of moisture, which can destroy the wood and lead to defects in the walls or roof. The material has a porous structure, so all the accumulated moisture dries out instantly, which means there is no reason for worry.

- Average insulation sags for 10-12 years, respectively, there may be cracks in the walls or floor. If insulation with penoizol is chosen, then this can be avoided, because it fills all the pores, and its service life can reach 70-80 years.

Independent reviews from construction forums

To understand the real effectiveness of the insulation, you should not unconditionally trust the words of sellers and manufacturers. It will be much more effective to refer to the reviews of real people who have already used the subject of our conversation for insulation. Immediately, we note that opinions on the properties of liquid thermal insulation are divided.

Not bad, but there is a small nuance. Alexander (www.forumhouse.ru)

Penoizol is an excellent alternative to any type of modern insulation. The price is quite acceptable, the mice will not be taken apart, the declared characteristics are at a high level. However, in practical use, a small drawback came to light: when the wooden walls were insulated, there were unfilled areas.

Friends advised. The house has a comfortable microclimate. Ildar (mastergrad.com)

We decided to insulate the walls with penoizol about 5 years back: outer wall made of block and bricks. Between the masonry left 6-7 centimeters free space. Glass wool, mineral wool did not give the expected result: the wall began to grow moldy, the rooms were pretty cool.

Friends advised penoizol. When the team worked, it was audible and visible how the insulation fills the space between the walls, appearing from the cracks. Now the house maintains a comfortable microclimate at any time of the year.

There are no complaints, but there were problems during the filling process. Mikhail (forumnov.com)

It is clear that seamless insulation has undeniable advantages. There are no complaints about the quality of insulation, however, for the equipment to work, a network connection is required 380 V... I did not have such an opportunity, which caused some difficulties in the filling process.

I really don't like the toxic smell. Konstantin (forum.vashdom.ru)

After pouring, penoizol noticeably decreased in volume, which already reduces the quality of thermal insulation. In addition, the material has an unpleasant and obviously toxic odor. They said that the composition includes formaldehyde, the use of which has long been abandoned in European countries. The house was recently insulated, so I can't say anything about the properties of the material, however, doubts about the correctness of the choice are already tormenting.

The price of the work bites. Edward (www.forumhouse.ru)

Personally, I am satisfied that penoizol will not be gnawed by mice, the insulation precisely fills any cracks, provides reliable heat and sound insulation. I did not like the fragility of the material, its susceptibility to deformation. And the total cost of the work bites a little.

How to insulate a house?

Let's start by answering the last question. In any house or apartment, especially in those that were built in Soviet times, heat losses are too great - they can reach 40%. In the end, you have to spend a lot of money on heating your home, since heat leaves our homes through the outer walls, floors, windows, doors, and also the roof. Modern methods of insulation, for example, insulation with penoizol, allow solving a number of important issues:

- The optimum room temperature will be maintained throughout the year.

- The walls will be protected from moisture, condensation accumulation, which means they will be reliably protected from mold and mildew.

- The acoustic properties of the building will improve.

- The level of noise insulation in the room will be higher.

- The hygienic condition of the room will be much better.

- Lower energy costs.

- The erected house will be more durable and economical to operate.

Of course, even insulating houses with penoizol will not completely protect the premises from heat losses, but at least they will be minimized. In addition, it is important that the installation of the insulation material is carried out competently and professionally in compliance with the technology.

Rules for pouring liquid foam

In order for penoizol to fully justify the hopes placed on it, it is necessary to strictly observe the pouring technology. If this is the first time you come across liquid thermal insulation, it is better to immediately contact specialists who can do the job with high quality.

Wall insulation is carried out according to the following scheme:

- Holes are drilled in the wall structures, where penoizol is pumped through the filling sleeves.

- Install a protective facade from a metal profile, leaving a gap between the wall and the metal 5-10 cm.

- Fill the free space with insulation.

- Are waiting 4 hoursso that the material grabs, cut off the excess insulation, proceed to the finishing.

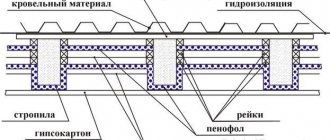

Roof insulation:

- The surface intended for insulation is covered with a film that should go onto the walls of the attic on 10-15 cm.

- Fix the membrane with staples.

- On top of the film, slats are stuffed.

- The space between the slats is filled with insulation.

- Are waiting 15-20 minutesto make the insulation viscous, the surface is leveled.

- Through 4 hours you can proceed to further work.

Floor insulation:

- Installation of wooden lathing is in progress.

- All sections are filled with insulation.

- When the material hardens, a plastic wrap is laid on top.

- The finishing is carried out: boards are laid or concrete is poured.

In principle, working with penoizol practically does not differ from the installation of other types of insulation.

Where is Penoizol used?

The modern homeowner is always faced with the choice of quality and reliable materials, especially when it comes to thermal insulation. Penoizol received positive reviews precisely due to the fact that it is a unique combination of price and quality. In addition, this material can be used to insulate both the floor and the roof both in new buildings and in existing buildings. Penoizol is a urea foam with a cellular structure. Due to its excellent physical and chemical characteristics, the scope of the material is wide enough. The material is released in the form of liquid foam, so it can easily fill all cavities in which it quickly solidifies. For wall insulation, you can also choose sheet foam.

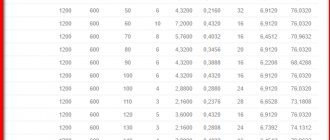

Consumption rates of insulating material per 1m2

When planning a budget for construction, you need to accurately determine the amount of material. To determine the amount of liquid insulation that will be required to insulate the entire building, it is necessary to know the consumption rates of penoizol per square meter.

According to the assurances of manufacturers, the consumption of liquid foam for 1m2 varies within 1-1.3 l.

To calculate the required amount of material, you need to multiply the length and width of the wall by the consumption rates declared by the manufacturer. For example: 7 * 3.2 * 1.3 = 29.12 liters. In this case, the final amount of thermal insulation must be taken with a small margin, counting on unforeseen situations.

Producers of urea foam in the Russian Federation

Penoizol is produced by many companies in Russia and Europe. However, in order to buy quality material, you need to take a responsible approach to the choice of the manufacturer. Therefore, we advise you to pay attention to the products of such companies:

- "New building technologies"... The company was founded in 1990, specializes in the production of thermal and waterproofing, fiberglass, fiber-reinforced concrete.Today, it is one of the main suppliers of penoizol in the Russian market. By the way, the rights to use this trademark belong to this company.

- Varmal LTD. This is a British company engaged in the production of liquid insulation flotofaum - the name of penoizol.

- LLC "Yuveis". Russian company located in the city of Orenburg. The manufacturer has been working on the market for a long time, so it carefully monitors the quality of the products.

In addition, customers give positive feedback on the products. LLC "ProTeplo", LLC "Penoizol-Omsk", CJSC "Murmansk Universal Plant".

Equipment features

Equipment for the production of penoizol is a number of units that are inexpensive. Firstly, it includes a gas-liquid plant, which directly produces foam insulation. It consists of GZhU, a supply hose, a set of valves for connecting tanks, as well as various application documents. Due to its compactness, the unit can be easily transported Secondly, you need a compressor that produces compressed air. Thirdly, for the production of penoizol, containers will be required - ideally, there should be three of them. In this capacity, ordinary polyethylene or iron barrels with a volume of 30-200 liters can be used. For the convenience of transporting the unit around the construction site, it is advisable to purchase a trolley with GZhU. Thus, to create such a material as penoizol, the installation must be completely assembled.