There can be no problems with cravings

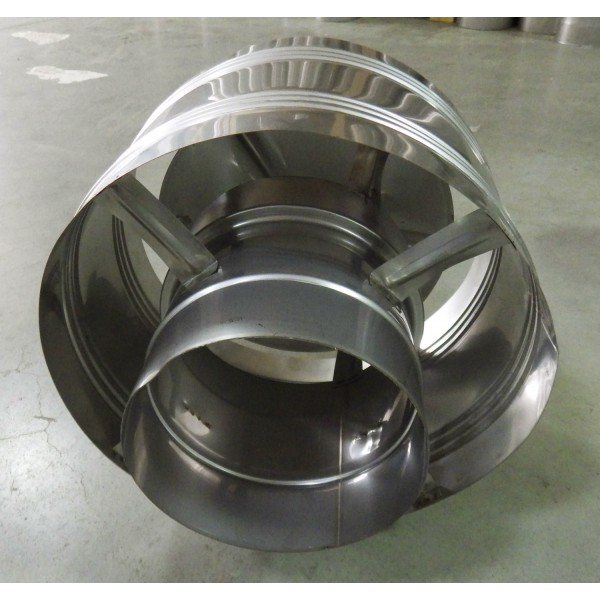

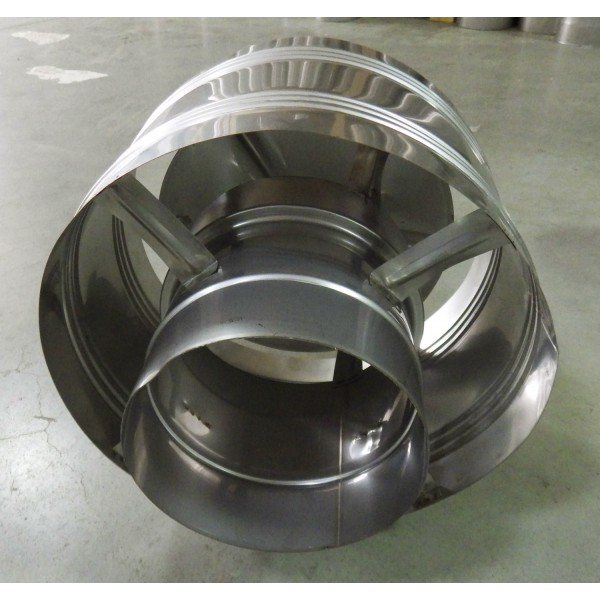

Rotary deflector ready to install

The meaning of any ventilation system is to remove polluted air, excess moisture from the premises, that is, to ensure normal air exchange. This will be the case if the ventilation duct is functioning efficiently and correctly - the draft in it is excellent. If there are problems in this regard, then they are often provoked by rain, snow, wind masses falling into the channel shaft.

Do-it-yourself tsagi deflector

| Author | Share | Rate |

| Victor Samolin |

Interesting on the topic:

The principle of operation and manufacture of ventilation deflectors

What exhaust technology to choose for your home

Three main technologies for installing a kitchen hood

Comments on this article

Sanya Kalyuzhny, Kharkiv thanks, I will make a deflector

09/18/2015 at 17:27KasparSn Thanks for the dimensions shown! The deflector for these coefficients turned out to be excellent, copes with its task without any complaints. 02/05/2016 at 15:59

Jordanbowl I made a cardboard deflector according to your plate. Everything worked out. It remains only to repeat on a stainless steel sheet. 04/13/2016 at 11:36

Arthur Now we are using a chimney without a nozzle. Is there any data on how much the efficiency of the thermal device will increase when installing the deflector? 05/10/2016 at 23:33

Gorin Hello! If you choose the right size and type of deflector, then the efficiency of the heating unit increases by about 20%. But this is not the only benefit, since the deflector still serves as protection against the ingress of precipitation and debris into the chimney. 05/11/2016 at 17:35

Ventilation deflector device

H-shaped design is effective in areas with strong gusty winds

Any type of ventilation deflectors contains standard elements: 2 cups, brackets for the lid and a branch pipe. The outer glass expands downward, and the lower one is even. The cylinders are put on top of each other, a cover is attached above the top. At the top of each cylinder are baffles in the form of rings that change the direction of air in a ventilation deflector of any size.

The rebounds are installed in such a way that the wind on the street creates a suction through the spaces between the rings and accelerates the removal of gases from the ventilation.

The device of the ventilation deflector is such that when the wind is directed from below, the mechanism works worse: being reflected from the cover, it is directed towards the gases that go out into the upper opening. Any type of ventilation deflectors has this disadvantage to a greater or lesser extent. To eliminate it, the lid is made in the form of 2 cones, fastened with bases.

When the wind is from the side, the exhaust air is discharged from the top and bottom at the same time. When the wind is from above, the outflow is from below.

Another device for the ventilation deflector is the same glasses, but the roof is in the shape of an umbrella. It is the roof that plays an important role here in redirecting the wind flow.

Varieties and design of modern deflectors

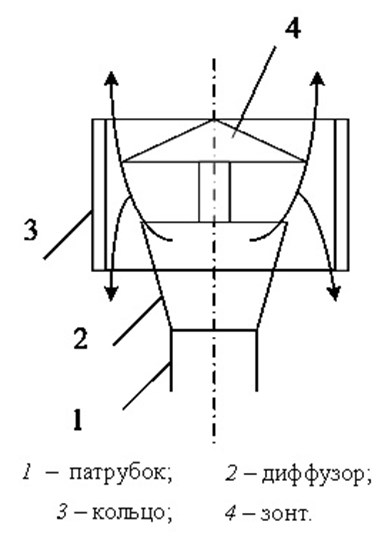

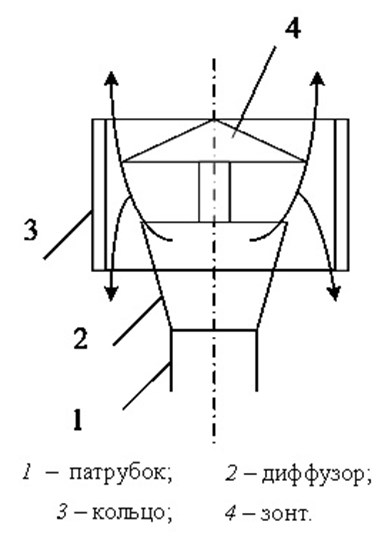

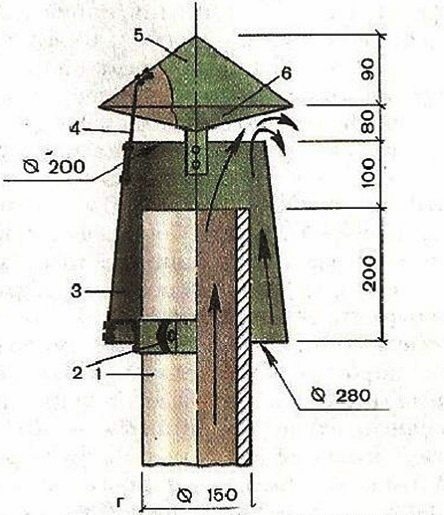

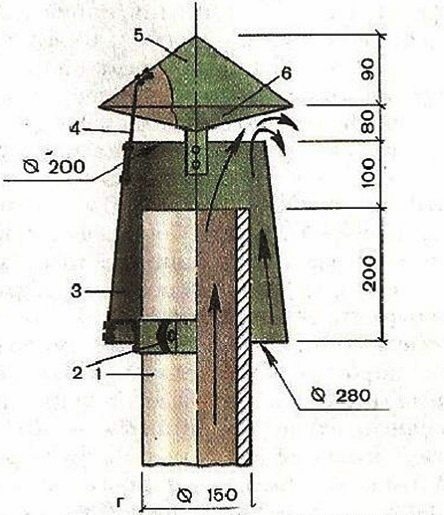

In its simplest form, a chimney reflector consists of several parts:

- inlet pipe;

- outer cylinder (diffuser);

- body;

- cap (umbrella).

In addition, the chimney is equipped with brackets that are used to connect its individual parts to each other, and some structures are also equipped with annular rebounds, which effectively protect the structure from precipitation.

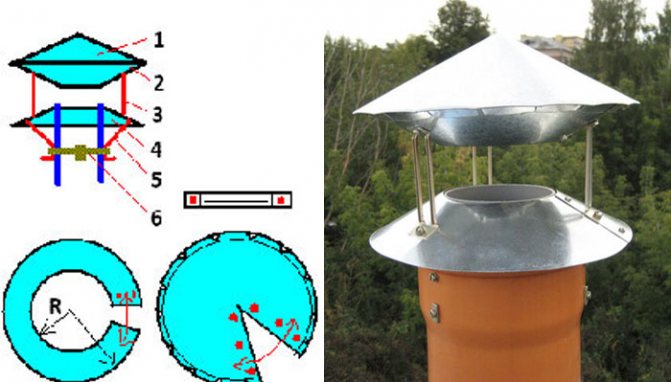

The chimney reflector has a simple design, so it is easy to make it yourself

As mentioned above, at the end of the 20th century, many reflectors were developed, which differ in both configuration and aerodynamic characteristics. Let's talk about the most popular designs in more detail.

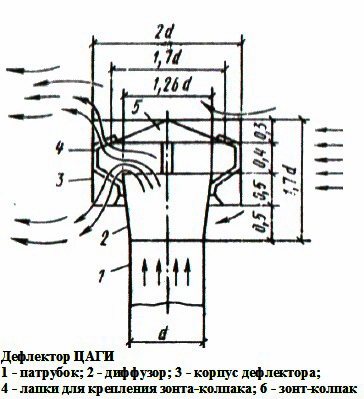

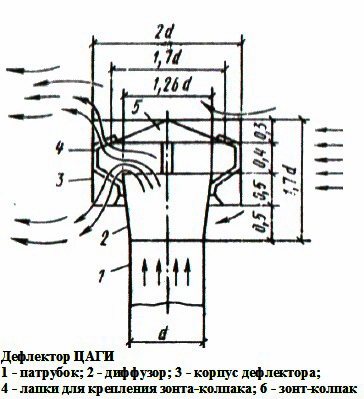

Deflector TsAGI

The reflector, developed by specialists from the Zhukovsky Central Aerodynamic Institute, is perhaps the most famous and repeated development in our country. The design has an open flow path and is distinguished by excellent protection against wind blowing into the chimney. At the same time, these advantages in winter time turn into some disadvantages. So, at low temperatures, the diffuser can be covered with a layer of ice, which will reduce the already small gap between the inner cylinder and the bell. Since the minimum flow area interferes with the natural draft of the chimney, TsAGI deflectors are best used for tall buildings and on terrain with constant air flow.

Easy to manufacture, but quite effective, the TsAGI deflector is one of the most popular designs among home craftsmen

Grigorovich-Volpert's reflective chimney

The design, which was proposed by the aircraft designer D.P. Grigorovich and the scientist A.F. Vol'pert, takes into account all the shortcomings of the TsAGI reflector. Using in their development a scheme with a narrowing channel, the engineers were able to increase the gas flow rate so much that the reflector began to work perfectly even in the complete absence of wind. Such a chimney is a real salvation for chimneys that are located in lowlands or are shaded by multi-storey buildings.

The Grigorovich reflector is an improved version of the TsAGI deflector

H-shaped reflector

The deflector, whose shape resembles the letter "H", has several significant advantages. So, the horizontal part of the structure allows you to divide the flow of combustion products into two parts, which is important for furnaces with increased productivity. In addition, the cross member protects the vertical channel from the penetration of debris and precipitation - the structure does not require an umbrella. Despite their outward simplicity, the H-shaped reflectors have two diffusers, which allows them to cope with even the most intense emissions from industrial furnaces.

Easy-to-manufacture H-shaped deflector is best suited for powerful heating units

Disc deflector

Just like the TsAGI deflector, the disc-shaped reflector has an open flow path - this, in fact, determines its effectiveness. It is no coincidence that the chimney received such a remarkable name - its design consists of several cone-shaped caps (plates), in the center of which there is a flue opening. In this design, the hoods directed towards each other form a narrowing channel, in which a vacuum occurs as soon as the wind blows from some direction. Due to their open design, disc deflectors are often wrapped in a metal mesh. Thus, the flue is additionally protected from debris, and the environment is protected from flying sparks.

The disc deflector is one of the most unpretentious designs

"Volper"

This chimney is almost a complete analogue of the device developed by TsAGI. The improvement is at the top of the device - the engineers just turned the protective cap upside down and installed it just above the diffuser. This was enough to prevent the formation of ice, which interfered with the operation of the original device during severe frosts.

Outwardly, the Volper has the maximum resemblance to the TsAGI deflector, but is devoid of its inherent drawbacks

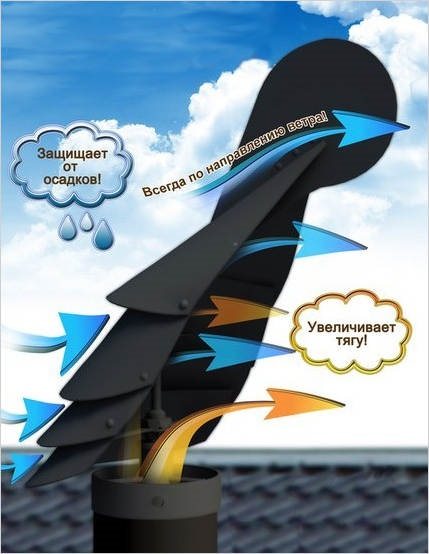

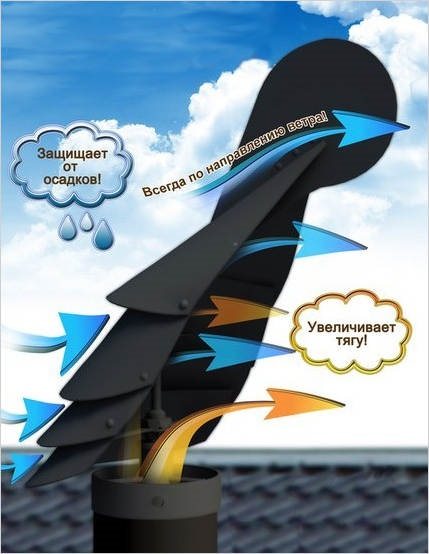

Constructions with a weather vane

Being a symbiosis of a simple chimney and a weather vane, devices of this type have a rotary cap (curtain). Turning around its axis during gusts of wind, the vane protects the chimney from blowing out and contributes to the appearance of a low pressure zone on the leeward side. Often, the curtain of a swivel chimney is decorated with various figures, which makes the design with a weather vane extremely advantageous aesthetically.

The deflector with a vane has a rotation unit, thanks to which it always occupies an optimal position relative to the incoming air flows

Spark arrester deflector

The design is based on the simplest chimney, which consists of a diffuser and a hood. In order to prevent the emission of sparks, the space between the individual parts of the reflector is covered with a metal mesh. In principle, any open-type deflector (such as a poppet) can be made safer by installing a spark arrestor. For this reason, spark arrester deflectors are more of a series of devices than a separate design.

A deflector with a metal mesh will not only increase traction, but also protect property from fire

Ventilation deflector selection

rotary deflector

The principle of operation of the exhaust ventilation deflector is very simple: the wind hits its body, is cut by the diffuser, the pressure in the cylinder decreases, which means that the draft in the exhaust pipe increases. The more air resistance the deflector body creates, the better the draft in the ventilation ducts. It is believed that deflectors work better on ventilation pipes installed slightly at an angle. The efficiency of the deflector depends on the height above the roof level, the size and shape of the body.

The ventilation deflector is frozen on the pipes in winter. On some models with a closed case, ice is not visible from the outside. But with an open zone of the duct, ice appears from the outer part of the lower glass and is immediately noticeable.

Most often, deflectors are used in natural draft exhaust ventilation, but sometimes they reinforce forced ventilation. If the building is located in areas with infrequent and weak winds, the main task of the device is to prevent a decrease or "overturning" of draft.

deflector ASTATO

Any owner wants to choose a deflector for ventilation as efficient as possible.

We suggest that you familiarize yourself with: How to decorate a relaxation room in a bath

The best models of exhaust ventilation deflectors are:

- disc-shaped TsAGI;

- DS model;

- ASTATO.

The deflector operation during calculations is determined by two parameters:

- discharge coefficient;

- coefficient of local losses.

For example, for DS, the coefficient of local losses is 1.4.

The vacuum coefficient is influenced by the wind speed.

Calculation of the deflector for ventilation type DS.

| Wind speed in km / h | 0,005 | 0,007 | 0,01 |

| Additional wind vacuum, Pa | 11 | 21,6 | 44,1 |

A method has been developed for selecting a ventilation deflector based on the total wind vacuum.

Although ventilation deflectors have been undeservedly forgotten in recent decades and have been widely replaced by umbrellas, today they are making a comeback. This is a really inexpensive and effective way to improve the performance of natural ventilation in residential and public buildings.

Please note that the hoods on the deflectors are more convex upward. This means that when bending around such an obstacle, a rarefaction is created in its lower part, and thus the formation of thrust.

What is a deflector and how does it improve traction

Probably, there is no such person who would not notice the bizarre hoods installed on the tops of chimneys and ventilation ducts. If you conduct a survey of what such devices are for, then the majority will answer that a deflector or chimney (as the stove-makers call it) is needed so that dirt and moisture do not get into the chimney.Of course, there will be more knowledgeable people who will say that a simple metal superstructure also serves to increase traction. And only a few will be able to explain how this happens.

The deflector installed on the chimney has been seen by many, but only a few know its structure and principle of operation.

At the same time, everything is simple. Most often, a decrease in thrust and a deterioration in the thermal efficiency of the furnace appears against the background of sudden changes in atmospheric pressure or with strong winds. Unfavorable weather conditions often even lead to reverse draft, causing smoke to form in the premises. And this is where the deflector comes to the rescue. Translated from English "deflector" is nothing more than a deflecting device or a reflector - these words perfectly characterize the principle of operation of a simple structure.

Installed in the path of the wind, the deflector forces the air flow around it around the periphery, contributing to the appearance of high and low pressure zones. If you remember the school physics course, you can remember Bernoulli's law - most modern traction amplifiers work according to the same principle. A thin atmosphere on the leeward side of the deflector creates an additional pressure drop between the blower and the upper cut of the chimney... As a result, the smoke is, as it were, forcibly “sucked out” from the chimney, thereby increasing the flow of air into the combustion zone.

The principle of operation of the traction amplifier is based on Bernoulli's law

The topic of chimney reflectors has recently been widely discussed in scientific circles, as a result of which many interesting designs have appeared. According to the studies carried out, some of them can increase the efficiency of a heating device by 20%. For this reason, the selection and calculation of the reflector is one of the most important stages in the design of direct combustion furnaces.

What the market offers

Turbovent

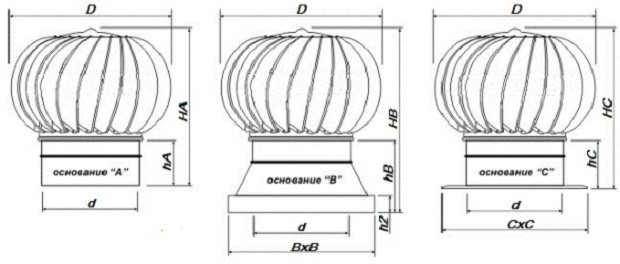

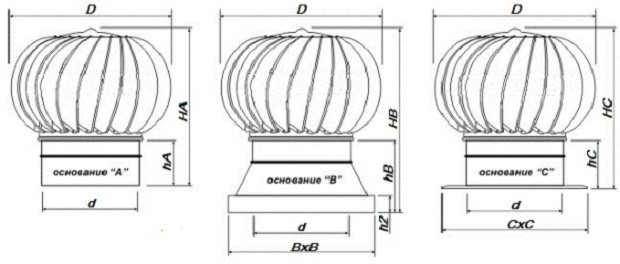

The range of rotary deflectors of this brand is represented by models of different geometric shapes, in terms of the immovable base:

- A - round pipe;

- B - square tube;

- C - square flat base.

Product marking in the assortment is presented as TA-315, TA-355, TA-500. The digital index indicates the diameter of the round or the parameters of rectangular bases. It is by them that one can judge the dimensions of the mechanism, as well as the scope of its application. For example, TA-315 and TA-355 are relevant when organizing air exchange in the under-roof space. But the TA-500 is a universal device and can be integrated into the ventilation of a residential building.

The diagrams indicate the parameters that must be taken into account when choosing a model.

The turbovent rotary deflector is produced in Russia - in the Nizhny Novgorod region, in the city of Arzamas.

Rotowent

Deflectors made of stainless steel made in Poland. Suitable for all roof configurations. Products are made of high quality stainless steel. The devices are universal - suitable for both ventilation systems and chimneys. The boundary indicator of the operating temperature is 500 C.

Turbomax

Rotary deflector manufactured by a company from the Republic of Belarus. The manufacturer positions its products as a rotating chimney hood Turbomax1. But it is also suitable for ventilation. It can be safely used in areas with II and III wind load zones. The company focuses the attention of consumers on the fact that they are ready to make a product to order according to the parameters for a specific object.

Self-production

Before you start creating a deflector, you need to stock up on the following materials and tools:

- steel sheet 0.5-1 mm (galvanized or stainless steel is suitable);

- scissors for metal;

- drill;

- riveter;

- cardboard.

Creating a drawing of a chimney deflector is a very important stage of the work.

To calculate the dimensions of the device, you need to determine the inner diameter of the chimney.This table will help you make the correct calculation:

| № | chimney inner diameter, d, mm | deflector height, H, mm | diffuser width, D, mm |

| 1 | 120 | 144 | 240 |

| 2 | 140 | 168 | 280 |

| 3 | 200 | 240 | 400 |

| 4 | 400 | 480 | 800 |

| 5 | 500 | 600 | 1000 |

If you did not find the required value in the table, then you can calculate the dimensions using the following formulas:

- D = 2d;

- umbrella width = (1.7 ... 1.9) d;

- full deflector height = 1.7d.

It is necessary to determine the diameter of the chimney and the parameters of the structural elements as accurately as possible. Calculations must also be verified. It depends on how well the deflector can be installed and how it will perform its functions. The shape of the pipe and device must match. For example, if there is a square section of the chimney, the deflector must be made the same. However, this shape can lead to less efficient operation of the device.

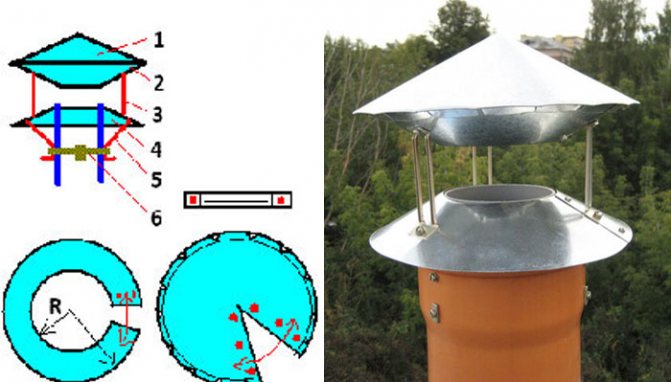

The sequence of actions is as follows:

- First, all the details are drawn on paper in full size and cut out.

- The paper elements are connected as they should be in the finished product. If everything fits correctly, you can repeat the same on metal.

- Paper elements are laid out on a steel sheet and outlined with a marker. Then the parts are cut out with scissors. In places where it is cut, the metal must be bent with pliers and tapped with a hammer.

- At the folds, the steel sheet is riveted to make it thinner.

- The diffuser is made from a piece of metal that is rolled up into a cylinder. Holes are drilled to connect the edges. The corners are riveted, bolted or welded. It is better to use not an arc, but a semi-automatic welding machine, so as not to burn through the steel sheet.

- The outer cylinder is manufactured in the same way. Next, a cap is made (a cone is rolled up from a piece of metal, the edges are connected).

- Then 3-4 strips about 20 cm long and about 6 cm wide are cut out of the steel sheet. They are bent and beaten with a hammer. Holes for bolts are drilled in the cap at a distance of 5 cm from the edge. The strips are attached to it and bent in the shape of the letter P.

- Using the brackets obtained, the umbrella is attached to the diffuser. Then the finished mechanism is inserted into the outer cylinder.

Installation features

Factory turbo deflector - one-piece design, ready for installation. It has an active movable top and a base that includes zero resistance bearings. The product is thought out in such a way that even in a strong gusty wind it will not tilt or carry it down.

Deflector with polymer protective coating

In conclusion, we would like to note that rotary deflectors in their segment are the most expensive ones. At the same time, the consumer is invited to choose a suitable structure made of stainless steel, galvanized or structural steel with a protective polymer coating, the color of which can be matched to the facade design. Of course, the type of material from which the deflector is made affects its cost.

Tags: ventilation, deflector, hand, your, drawing

«Previous post

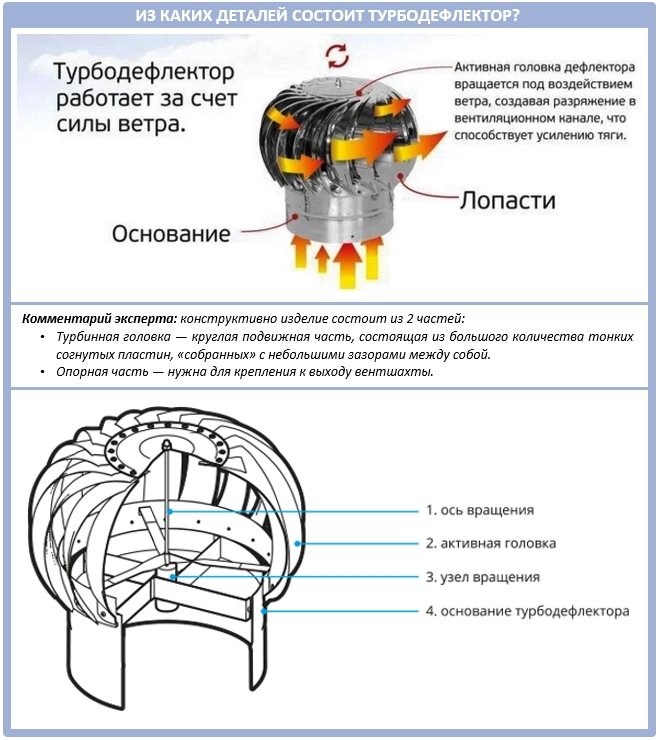

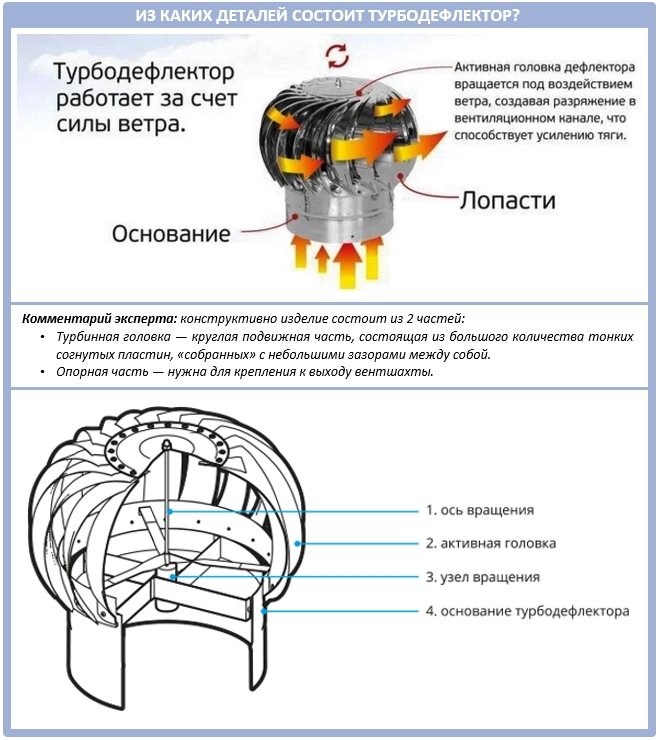

Ventilation turbo deflector design

Structurally, the device can be divided into upper and lower parts. The upper part is an active head that rotates under the influence of the wind. The vacuum that is created in this case in the ventilation duct leads to an increase in draft. The main structural part of the head is the blades, which, in addition to rotation, also protect the ventilation duct from snow, rain, dust, dirt, debris, etc.

- The head is held in place by bearings to ensure smooth rotation of the blades. The design provides uniform rotation of the blades in one direction in any wind, including intermittent. The power of the turbo deflector is proportional to the strength of the wind. The blades are made of light and thin material (thickness 0.5 - 1.0 mm). A wind speed of 0.5 m / s is sufficient to rotate the head part.

- The lower part of the deflector is used for attaching to the ventilation duct.It can be round, square or rectangular depending on the shape of the ventilation hood.

- The turbocharged design is stable, unlike a conventional deflector, which tilts over time from the wind and often falls off the head.

- The material for the manufacture of a turbo deflector can be sheet aluminum, stainless steel sheet, galvanized sheet or painted black sheet metal. Bearings are used to fix the elements and rotate the turbo deflector.

Such deflectors are installed at the highest point of the roof. They are placed along the ridge with a step of 4-6 m. For ventilation of the attic only, the TA-315 turbine is used, which provides an exhaust space of 50 - 80 m2. Fewer turbines are installed on steep roofs than for shallow ones.

How to assemble a turbo deflector by yourself?

The turbo deflectors themselves are relatively inexpensive today when compared with other roofing elements. And in the process of operation, they do not need any additional costs.

But, if you still want to customize and make such a product with your own hands, we will tell you in detail and show you in practice how to do it.

Step 1. Design and drawing

If we are talking about an ordinary country house, then a turbo deflector with a standard diameter of 315 mm is quite suitable for you. Such is able to serve a house with an area of 80 square meters.

But you'd better be guided by these numbers:

- for ventilation of such small rooms as a basement, garage or room, a turbine with a base diameter of 110-116 mm will be enough;

- if the room has an area of more than 40 square meters, then make the base with dimensions from 200 to 600 mm. The same applies to a room in which up to four people are constantly present;

- if you need to provide fresh air to a warehouse or even a whole farm, then you need a turbo deflector with a base from 400 to 680 mm;

- but for ventilation of the under-roof space, a 315 mm turbo deflector is ideal, because it is designed to ventilate 50-80 square meters of the roof. Just keep in mind: the smaller the angle, the larger the turbo deflector will have to be installed;

- in rooms where air pollution is increased, the turbo deflector cannot be used as the only means (although it is effective).

In total, the outer dimensions of the deflector itself will be equal to the pipe diameter plus from 80 to 120 mm. And in order to make your own product, it is better to take a drawing from an industrial turbo deflector as a basis:

But it is also important to understand exactly how the durability of such a device is ensured. So, in the industrial model, special bearings are used that can withstand significant temperature drops from -50 to +50. Whether it will be possible to install them at home is another question, of course.

Step 2. Selection of materials of manufacture

For each element of the turbo deflector, manufacturers carefully select the material according to certain technical requirements, which are calculated depending on the loads.

For example, for all external elements, an aluminum alloy of special grades is used, necessarily electropolished, or at least galvanized or laminated sheet metal, or stainless steel. Stainless steel, of course, is better in that it has a certain property of self-healing, in which a special film of chromium oxide helps it:

The main requirement for the materials themselves is to provide the deflector with strength, wear resistance and durability. After all, remember that such roofing elements always work in conditions of high humidity, under the pressure of wind and rain.

That is why all the working parts of the turbo deflector are made of either specially painted metal, or galvanized or stainless steel. But, if galvanized metal is used, it is important to carefully check all products for scratches that will not turn into rust in the future.

It is imperative that the internal components do not rust over time. Therefore, usually, when a turbo deflector is independently manufactured, its central axis is made of durable stainless steel, but the vertical supports and radial elements for the sake of a significant reduction in the weight of the structure are already aluminum.

Remember also that sophisticated assembly jigs and even laser cutting are used to produce industrial models. The entire production line takes up a lot of space in the workshop, so try to make a high-quality deflector, but do not demand much from it in the end, especially in terms of durability.

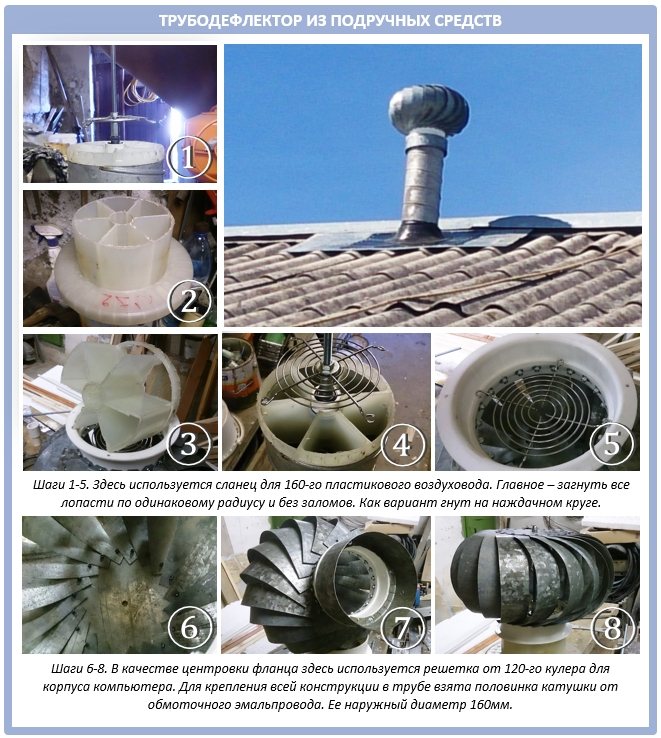

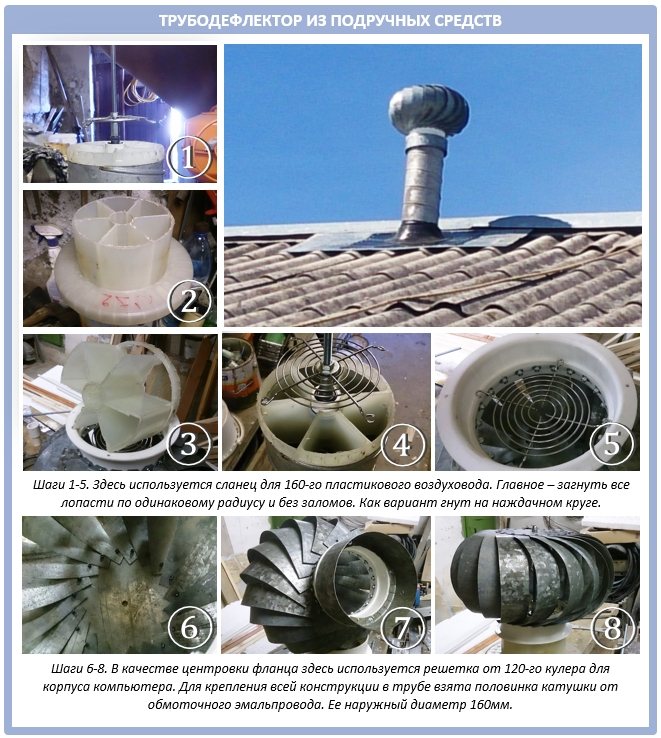

But for this homemade deflector, the most unusual materials were used:

Indeed, quite often when making a turbo deflector on your own, plastic is used as a cheaper material.

The only thing is that in severe frosts, ice can form on the inner walls of the cylinder, which impedes its movement. But since you are already doing everything with your own hands, you can play with the shape of the deflector. Indeed, even on sale, they are found not only in a spherical shape, but also in a conical and cylindrical one.

Step 3. Manufacturing of individual parts

Next, you will need to cut out all the elements of the future structure from a metal sheet using metal scissors, a jigsaw or a chisel. Treat them with an electric grinder or a file.

Here are some meticulous measurements of a standard industrial turbo deflector that you can use as a guide:

The next step is to use a lathe to roll the upper fairing on it using the same technology as used for making table bowls. At the same time, make sure that where the passage of air is not desirable, there are minimal clearances.

Important note: make sure to make the upper disc a little larger than that of the pipe.