The principle of operation of electrode boilers

The principle by which the coolant spreads through the heating system depends on the type of equipment:

- If the system is of a closed type, the installation of a circulation pump is required, otherwise the movement of the coolant will not occur.

- With an open system, the coolant flows naturally.

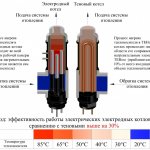

The job is to comply with the laws of physics. The liquid heats up because the water molecules break down into differently charged ions.

The coolant heats up due to the movement of ions between two opposite electrodes. Chaotic movement of positively, negatively charged particles is created, thermal energy is released. Energy is used to heat water, antifreeze.

Principle of operation

Electrodes - manufacturers of electric field with variable action.

The heating method eliminates the formation of scale on the walls of the heating equipment, prolongs the service life.

Coolant requirements

The electrode boiler is very sensitive to the composition of the coolant. Plain tap water will not work. It is necessary to purchase distilled water, add a little table salt. Proportion: 100 grams of salt per 100 liters of liquid.

Ready heat transfer fluids

For normal operation, the liquid must be brought to the desired density and conductivity. Salt varies in composition and results may vary.

When completing the preparation of the solution, be guided by the value of the current in the electronic boiler. In the instructions for the device, you can find a detailed table of the required values. They are taken depending on the power, the volume of the filled coolant. Gradually adding salt, distilled water, you need to achieve the required performance.

Before filling the system with electrolysis solution, carry out mandatory cleaning from scale and salt deposits. If not, the problem can change the thermal conductivity of the liquid.

Pros, cons of equipment

Customer reviews of electrode boilers are very different. Benefits:

- The device is compact. The device can be transported without problems.

- The device is easy to connect.

Installed device

- Due to the small size of the device, it can be used as an additional, backup heat generator.

- To install the device, you do not need to draw up a project, contact the service for approval.

- If a coolant leak occurs, the device will function as before. After fixing the problem, you can restart the device in operation.

- Electrolysis boilers are comfortable with voltage drops.

- They do not emit harmful substances, do not create powerful electromagnetic fields.

Disadvantages:

- The use of steel, cast iron radiators in the heating system is unacceptable. For efficient work, you need devices made of bimetal, aluminum. The nuance makes the system more expensive.

- The use of tap water is not permitted. It is necessary to use distilled water mixed with table salt when making electrolysis liquid.

Ban on tap water

- The boiler can be installed in a closed circuit. Requires the purchase of a sealed expansion tank, an emergency pressure relief valve, an air vent.

- The heat carrier should not be heated above 85оС.

After analyzing the minuses of the apparatus, one can understand what are associated with the quality of the coolant, chemical properties.

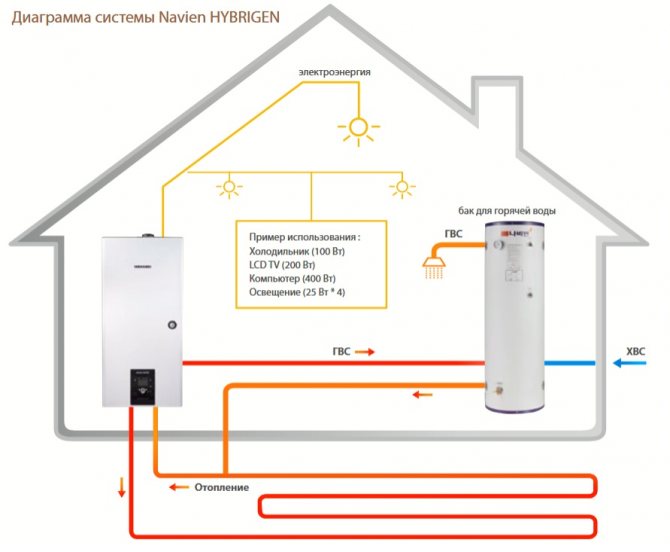

Gas boilers for the home are converted into gas generators to generate electricity

Far from all the powerful energy in gas boilers for heating and obtaining hot water in millions of individual residential buildings is used rationally. And now, it seems, the issue has been resolved when gas boilers for a home are converted into gas generators to generate electricity, which is just great. Although the technology of generating electricity using gas generators is no longer new in industry.

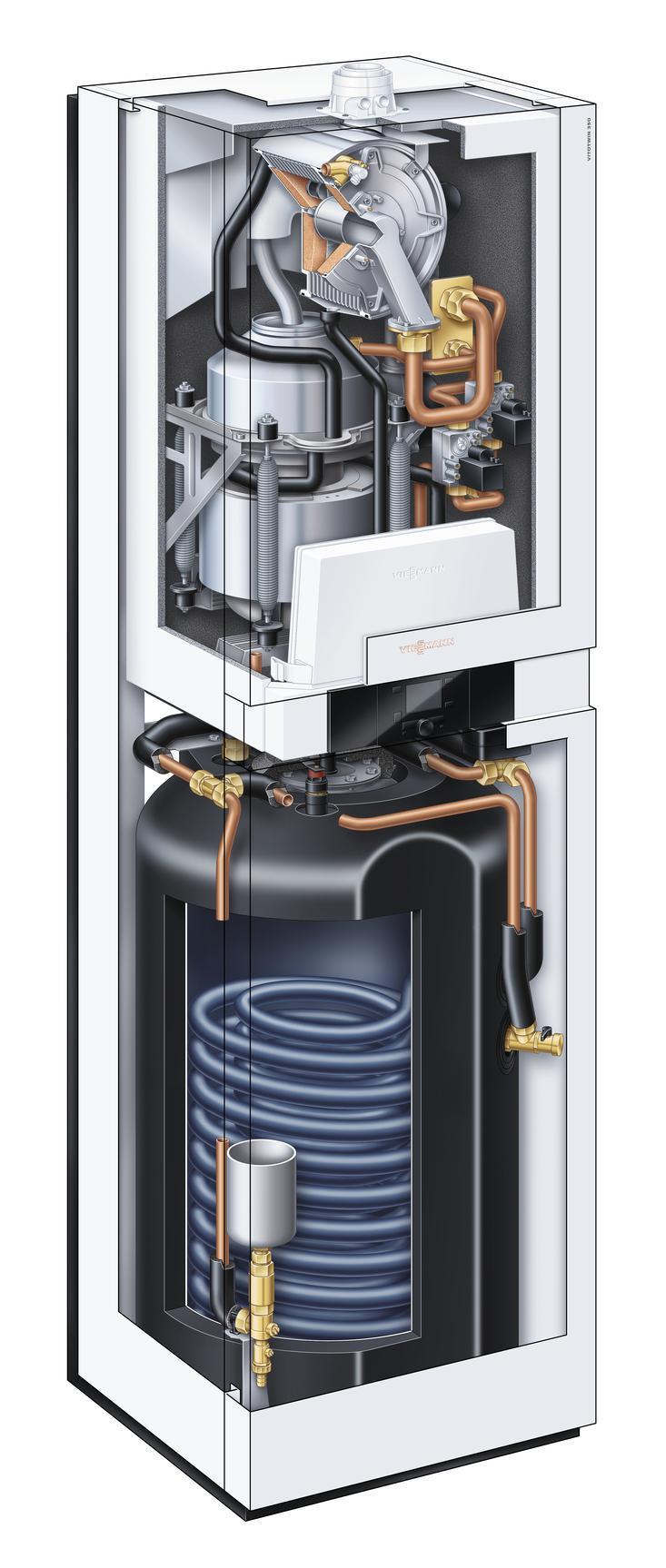

Developed by a British firm, the new boiler can reduce energy costs for families by converting their homes into mini power plants.

Such a boiler provides heating and hot water supply, as well as the generation of a built-in generator of electricity to power household appliances.

The boiler manufacturer argues that the reduction in the cost of electricity through the use of a multi-functional boiler may ultimately allow conventional power plants to be abandoned and shut down.

The first of the boilers will be installed in early 2020. Savings for the consumer after the costs incurred for the purchase and installation of the boiler are seen in five years. Initially, for the interest of the consumer, the company will make an additional payment to him associated with an increase in the cost of the boiler due to the complication of its design. According to the company's calculations, the boiler with a gas generator will allow not only satisfying its own needs for electricity, but also shipping its surplus to the power grid and selling it to other consumers. Here, of course, some legislative acts will need to be revised. At the very least, it is estimated that households could end up with £ 500 less per year by generating electricity from gas-fired boilers and selling surplus energy as well.

If homeowners agree to share these benefits with the company, they will receive an extended generator warranty after a five-year contract.

As you know, in a conventional boiler, gas is burned to heat water, which is then passed through pipes and radiators to homes. In contrast, in a new boiler, the flow from the combustion of gas heats another liquid - a refrigerant similar to that used in refrigerators - until it evaporates. The steam then passes through a device called a scroller - an expander, which spins around, acting like a mini-generator of electricity. The heat from the steam is then transferred to the water in the boiler, which goes to the hot water taps and heating radiators in the house.

Such a boiler has a slightly higher gas consumption, which increases the cost of paying bills by about £ 50. However, comparing with the win, we will see that the win is many times more significant.

So far, a gas boiler with a gas generator is free for the consumer, but customers have to pay for its installation.

The boiler generates a lot of electricity to its maximum during the heating season, however, during the summer, electricity generation is very small or absent, since the gas is burned only for the purpose of heating water. But, at the same time, a boiler with a gas generator can generate about 1800 kW / h of electricity per year, which is about half of what is used in a house for typical household needs. In general, the technology is also more efficient due to the proximity of the source of electricity to the place of use, which eliminates the need for electrical networks. The company claims that by installing 20 million boilers across the UK, consumers will save more than £ 4bn a year on their bills.

But this also has great environmental benefits. Installing gas boilers with gas generators to generate electricity will reduce carbon emissions from the closure of 30 coal-fired power plants.

Gas generators are widely used in industry in everyday life.But they all run on the original solid fuel, including waste. This boiler uses gas, which is universally used for completely different purposes - heating rooms and heating water. And this burnt gas, in addition to achieving the main goals, will simultaneously generate electricity, which the homeowner can ship to other consumers.

Is this article helpful? Then let others know about it by clicking on the social media buttons (Twitter, Facebook, etc.) below. Most likely, the following entries will be interesting and useful to you: Warm house - heating on wood, gas, electricity, diesel fuel, tariffs and how much it costs, as well as a subscription to new interesting site materials through the orange button at the top or in the side column on the right.

Consequences of electrolysis, direct current action

During the operation of the hydrolysis solution, water decomposes into hydrogen, oxygen, and leads to the formation of air pockets. Prevents fluid from circulating normally within the system.

Some users have found signs of corrosion on aluminum radiators - a consequence of electrochemical exposure.

If cast iron radiators are installed in the heating system, the quality of the coolant will change for the worse. Distilled water removes impurities from the pores of cast iron. The electrode boiler requires the installation of bimetallic structures.

The fluid in the system is under constant current, and grounding is required. The process is complex, not possible on all types of heating systems.

A clamp can be installed on a steel pipe, if the system consists of cast-iron radiators and plastic pipes - the process is almost impossible to solve.

Organization of a home heating system without gas and electricity

To select alternative heating options for a non-gasified electrified house, with a low power consumption limit of up to 5 kW, several effective heating sources can be offered. To heat a house, you will need to choose one of the heat supply schemes using the following modern technologies:

- Long burning boiler, with two heating circuits for heating and hot water supply and a tank for indirect hot water heating. As a fuel for such a structure, you can use an affordable and cheap solid fuel: firewood and its waste, coal or anthracite and any other fuel products in the form of briquettes / pellets.

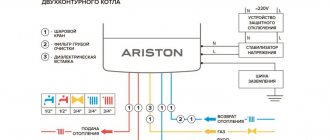

- The boiler is double-circuit, operating from liquefied gas obtained from a cylinder or gas-holder installation.

- LPG gas convectors.

- Double-circuit boiler for liquid fuel: heating oil, diesel fuel or oil refining.

- Renewable natural sources: wind power plants, solar collectors and various heat pumps.

After the heating source has been selected, the home owner will need to perform organizational measures in order for the scheme to become operational.

The stages of organizing a heating system in a simplified form can be represented as follows:

- Before heating a house without gas, they carry out a heating project and develop schemes for in-house heating systems.

- Obtaining approval from the regulatory authorities for the start of operation of boiler equipment. In this case, these are approvals from the gas service for connecting to a gas tank or installing cylinders of liquefied gas, a distribution zone and a water utility.

- Inviting a specialized organization for the installation and commissioning of the boiler and other boiler equipment.

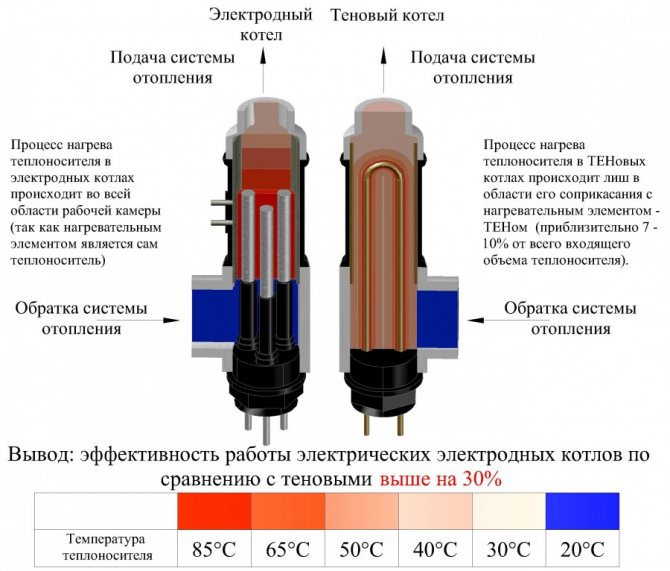

Outstanding efficiency myths

The advertising materials claim that the boiler equipment on the electrodes extracts thermal energy from the void. Indicators - 120-150% of the applied electrical power. But they completely do not pay attention to the laws of physics, heat engineering.

Myth - the conversion of electrical energy by an electrode boiler many times over.We focused on the promotion of heat technology, which operated from a heat pump with a positive COP coefficient.

Do not believe the statement that electrical energy is 100% converted into heat. Losses are inevitable.

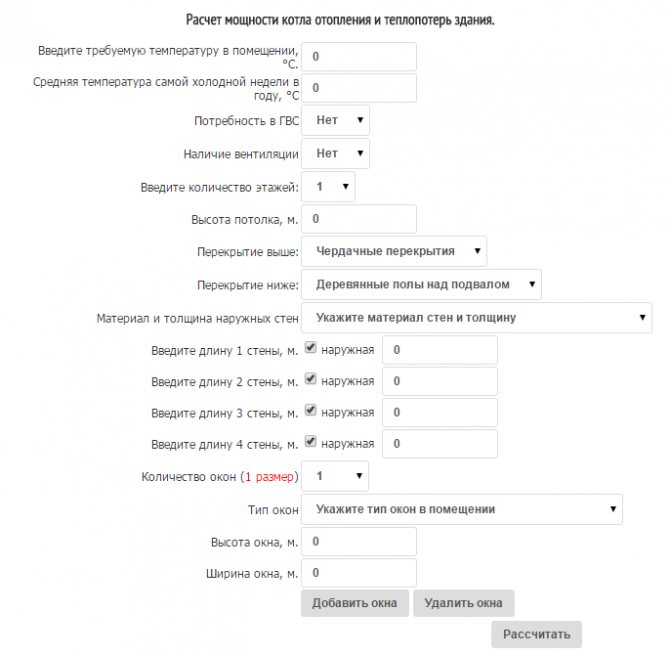

How to calculate the capacity of a power plant

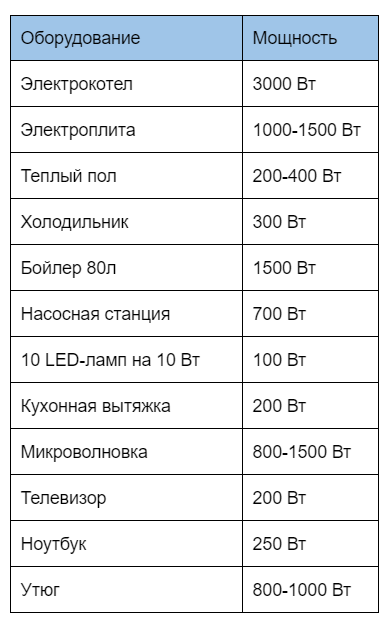

The denomination is selected according to the number and total power of electrical equipment in the house. Suppose that the newly built house is not yet supplied with gas, therefore it is heated with electricity, and there is an electric stove in the kitchen. An electrical engineering kit will look something like this:

Provided that everything works at the same time, the load on the network will be about 10 kW. But, it is important to understand that such a situation is unlikely.

For example, a pumping station will operate only to fill the tank with water, and the boiler will consume the rated power only during heating. An electric stove, iron, extractor hood, microwave oven will create a temporary load, they will not be turned on all the time. Thus, when you are at home, the average load on the network will be 6-8 kW with a possible jump up to 9 kW.

And now we will calculate the power of the network in your absence. In this case, only the refrigerator and electric heating, including underfloor heating, will work. The network will have a stable load of 3.5 - 3.7 kW.

Based on the calculations, you will need a backup source that supports the load in the range of 3.5 - 8 kW, with a possible peak up to 9 kW. For such a network, it is necessary to take a backup source of 10 kW.

The fact is that the optimal load on the generator is considered to be 40-80% of the nominal value. With prolonged operation at maximum load, wear of parts will increase and it may fail.

On the other hand, it may seem that 10 kW is too much, because in summer, for example, electric heating will not work. But, in hot weather, you turn on the air conditioner, and this is still somewhere around 1.5-2 kW, so this rating will be enough.

Moreover, working at too low power is not as destructive as at maximum. If the generator works like this for about an hour, nothing will happen. Always it is better to take the face value 15-20% higher

maximum network power. Also, keep in mind that the network can expand, for example, if you decide to buy another refrigerator or multicooker.

Knowing the average load on the network, it is easy to calculate how much it will cost to operate the backup source.

Feasibility of use

Used for heating small rooms. Electrode-type equipment has a slight inertia, heating occurs almost instantly, in a short time you can heat a small room.

With its compact size, it can be placed in any part of the heating system.

Electrode boilers are designed for closed-type systems where displacement is minimized. The device can be used for heating floor heating, radiators at the same time. The process requires careful preparation of the coolant, complex electronic thermal control circuits.

Heating system maintenance on electrode equipment

Electrode boilers are a technical development for heating a summer cottage with a small area. A feature that distinguishes it from a device operating on a heating element is the impossibility of breakdown from a voltage drop.

During the operation of the device, operating at the limit, a high temperature and pressure are formed inside the case, a circulation of low-quality coolant occurs, the device wears out very quickly. In such conditions, electrodes, insulators wear out, the tightness of the joints will become unusable.

In case of poor-quality heating of the coolant, leakage, urgent equipment repair is required. Before starting work, the device must be de-energized.

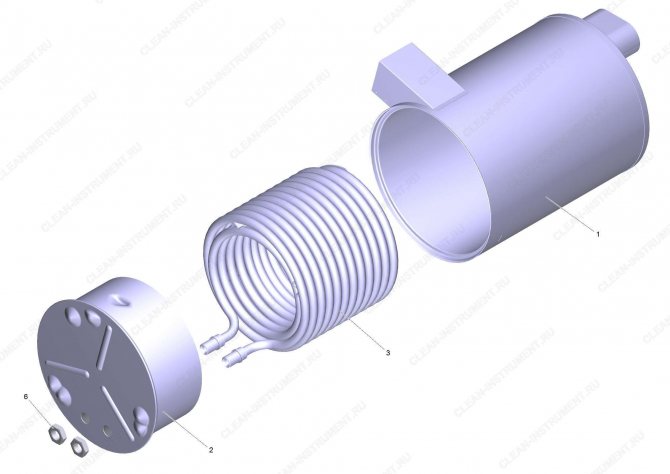

Cleaning the appliance

- To carry out maintenance, you need to dismantle the device. Unscrew the screw connection on the flange, pull out the electrode.

- Assess how worn out the electrodes are. Make sure insulators are intact. There are no cracks on the case.If the electrodes are worn out by more than 40%, equipment replacement is required.

- Clean the surface of the electrodes, holders.

- Clean the inside of the case.

- You can assemble the device in the reverse order.

- Degrease surfaces, apply sealant. You will need a high temperature substance.

Repair kit

Testimonials

“I retired, took up the dacha chores, it is cool in the spring and autumn periods. I wondered how to heat the dacha. I recently purchased an electrode boiler. My house is insulated, protected from wind blowing, I arranged the option. The boiler does not work all the time, everything is in order. "

Nadezhda, Stary Oskol.

“My wife and I bought a device specifically for our summer cottage. Guys, the boiler is working well. I have not tried it in large rooms. Can be installed in a room without bothering to allocate a separate room for a boiler room. I advise. "

Vladimir, Krasnodar.

Differences between gas boilers depending on the type of removal of combustion products

The process of removing combustion products can occur in two ways:

- If there is no stationary chimney in the room, then a forced draft gas boiler will do. The combustion products will be removed through a coaxial chimney. For its device, you need to make a hole in the wall. In another way, such a chimney can be called "a pipe in a pipe". Air enters through the outer pipe, and combustion products are removed through the inner pipe.

- Natural draft gas boilers. The combustion products are removed by means of a draft in the chimney. For the installation of such equipment, the installation of a chimney is required.

Forced draft gas boilers do not burn oxygen in the room, and there is no need for air flow from the street.