What is it?

When we talk about plastering work, we mean the complexity of their implementation and the need to attract experienced craftsmen. However, the problem is that ordinary cement plaster does not solve the problems of wall insulation.

In order to create an additional insulating layer, heat-insulating plaster is used for external and internal walls. The material has a high energy efficiency, and its cost is quite acceptable.

Preparation of the mixture

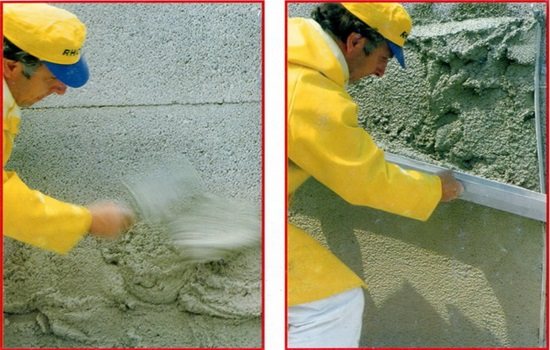

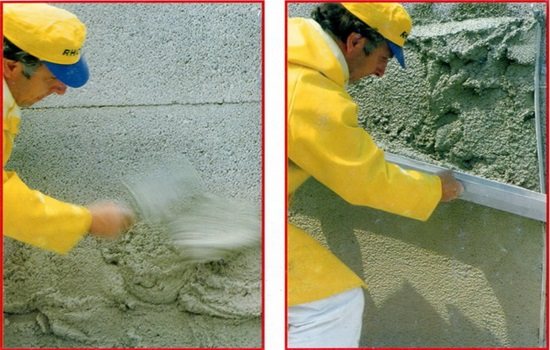

The mixture purchased from the store must be diluted with water in accordance with the instructions. It is not recommended to use the entire composition at one time, as in this case it will not be possible to obtain the correct consistency. It is necessary to mix the mass thoroughly, leave for 4 minutes. During this time, it will "mature". Experienced craftsmen prepare warm plaster in this way: they take 4 kg of vermiculite and mix it with 1 kg of cement powder. The solution should be thick. After cooking, it is kept for 15 minutes.

What does it consist of?

Typically, the plaster material is a mixture of sand and cement, which creates a coating with a density of up to 1,800 kg per cubic meter and a thermal conductivity of 1.2 W / mS.

Heat-insulating plasters are made of cement and fillers, which create air bubbles in the monolithic coating, which reduce the density and the ability to transmit heat. Various materials can be used as a filler:

- perlite. It is formed when volcanic lava solidifying on the surface of the earth comes into contact with moisture. In the process of hydration, rounded nuclei, called pearls, are formed. A distinctive feature is a high porosity, the ability to absorb water in large quantities, ten times its own weight. In the preparation of the plaster mixture, as a rule, expanded perlite is used - small granules of grayish or white shades;

- vermiculite. A representative of the group of minerals, outwardly resembling small-sized scales of a brown-golden color. Swells from heating, fills with air. In this form, it is used in various industries, including construction, in the preparation of light concrete mortars and warm plaster compositions;

- small expanded clay chips. For production, special grades of low-melting clay are used. Granules are small, do not exceed five millimeters, more often they are compared with sand. The filler is lightweight, airy, with minimal thermal conductivity;

- sawdust. Waste obtained from wood processing is also used as a filler. With their help, the plaster mortar is provided with porosity, while the structure of the mass and its homogeneity are completely preserved;

- polystyrene foam granules. They are used as insulation in the preparation of plaster mix. They are a product of the chemical industry, analogs of natural origin are inferior in resistance to fires, biological influences and the period of operation. But they do an excellent job with the assigned function - they give the plaster mass porosity and reduce its ability to transmit heat.

In addition to the main listed components, modifiers can be added to the plaster mixture that increase elasticity, increase the service life, and protect against cracking.

Manufacturers add plasticizers and water repellents to dry formulations; for self-preparation, many use microfiber, detergents and ready-made modifiers.

Insulated plaster applied to the walls is not inferior in its qualities to the analogue of sand and cement. Any kind of finishing is applied to it.

Applying warm plaster

Warm plaster is offered for sale as insulation. But construction experts do not consider this material as a possible alternative to heaters for thermal insulation of buildings. And only in some cases is it recommended for use. Why? Is it necessary to carry out insulation with a heat-insulating plaster layer? How to apply correctly?

What is the difference between warm plaster

The answer why warm plaster cannot compete with insulation in conventional insulation technologies lies on the surface. Its thermal conductivity coefficient is 0.065 - 0.12 W / mK, while for conventional heaters it is 0.033 -0.04 W / mK. Those. almost 2 times.

To achieve the effect that is obtained from the use of conventional insulation, the layer of warm plaster should be 2 times thicker. If for the facade the usual expedient layer of insulation is 10 cm of polystyrene, then only 20 cm of plaster can replace it.

But such a layer is impossible - too heavy, threatens with collapse and danger. With insulating plaster, it is simply very problematic to even achieve the values of heat transfer resistance prescribed in SNiP. This prevents this material from being reliably registered in those. documentation.

Not profitable

In addition, the cost of warm plaster is 2-3 times higher than that of insulation of the same volume. As a result, we get a 4 (!) Times loss in terms of money investments in comparison with “conventional methods” for heat saving $ / W. There is no economic feasibility of making direct thermal insulation with the material in question.

It should also be borne in mind that heat-saving plaster is not a finishing material. Its surface, as well as insulation, must also be covered with a final finishing layer.

Varieties

To decide on the choice of warm plaster, you need to take a closer look at its composition and characteristics.

Plaster becomes heat-saving due to the presence of granules, insulation particles in the composition. Most often, the same foam is used as part of a sand-cement mixture with plasticizers and bonding additives.

Another common base for warm plaster is expanded vermiculite and / or perlite.

Plasters based on these materials have similar properties in terms of thermal conductivity, but vermiculite plasters are distinguished by high water absorption, therefore they require protection from water ingress, are not used in basements, on the foundation ....

There are also mixtures based on sawdust and cellulose. They have less cost, but the thermal conductivity is much higher, and the specific gravity is higher.

To choose warm plaster, you must first determine the places where it is possible to use. Let's take a closer look. Let's consider in order the advertising statements of manufacturers about the purpose of warm plaster.

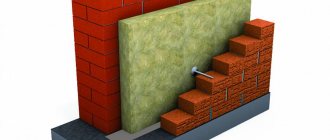

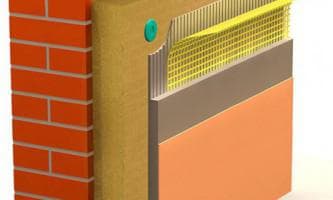

The wall remains single layer

Insulation of facades, walls, ceilings. First of all, walls are made of large-format blocks - aerated concrete or porous ceramics. The increase in the thickness of the masonry of these materials entails a significant increase in cost, and not only the walls, the requirements for the foundation are increasing. Heat-saving plaster will help to bring the resistance to heat transfer of a wall from warm blocks to the requirements of standards.

Most importantly, the wall will remain single-layer - only the bearing layer of the blocks. A single-layer wall has very significant advantages over multi-layer, with a layer of insulation, primarily in terms of durability.

Leveling of surfaces and thermal insulation of pipelines.

In fact, the same thing - both pipelines and walls need to be insulated to the maximum.Typically, pipelines are insulated with a sheath of extruded polystyrene foam with the best effect. But sometimes it is required to warm up already laid pipes, and this is usually easier to do only with warm plaster.

Warm plaster can be applied in a layer of considerable thickness, and therefore, it can be used to level very uneven surfaces.

A significant layer can be placed where it is difficult to insulate heat - in hard-to-reach places, closed cavities ...

Characteristics

Typical characteristics for warm polystyrene-based plaster: Thermal conductivity coefficient - 0.7 W / mK. Flammability group - G1. Specific gravity - 200 - 350 kg / m3 Water absorption - 70%. Cost - from $ 30 / sq. M.

Why you can use insulating plaster

Warm plaster should be applied in accordance with the manufacturer's recommendations. But this does not mean that the best solution will be obtained in terms of insulation.

A specialist should make a decision on wall insulation (additional insulation) with warm plaster, or such a decision should be in the project documentation.

Also, warm plaster can be suitable for sealing any cracks, hard-to-reach places, joints of structures, where the "adaptation" of the insulation is most problematic, and a snug fit does not work.

On the wall on both sides - weighty additional insulation

The possibility of applying warm plaster from both sides - from the outside and from the inside - may also be considered. In this case, a very significant insulating effect can be obtained, for example, on a wall made of porous ceramics. From the inside, it is recommended to use plaster without expanded polystyrene, the environmental friendliness of which is questionable.

For such a material as warm plaster, with its significant cost, there are also places of application where it will be optimal and expedient. First of all, this is an increase in the resistance to heat transfer of enclosing structures made of heavy and light materials, while maintaining a single layer. Read more about warm single-layer walls made of ceramic blocks Also, insulation with warm plaster will save heat, where it would seem that heat loss is inevitable ...

Video - application process

How warm plaster is applied can be seen in the film

Leading manufacturers

This insulating plaster has been produced recently, but manufacturers have already begun to compete. Today, the following brands are especially popular:

- mix "Umka". A renowned material, excellent for interior walls. The basis is made up of granular silicon balls. The composition is distinguished by good vapor barrier, resists moisture, protects against extraneous sounds, and retains heat perfectly. The filler does not smell, does not harm the human body. Granules add extra strength to the surface. After applying such a composition, there is no need for priming or wall reinforcement.

- "Bear" or "Warmix". Some confuse these building materials, although it produces them in an untreated state, represented by a dry mixture, immediately before use, diluted with water in the right proportions. The ready-to-use mass is characterized by high adhesion to various surfaces, which makes it possible not to cover the walls with primers. This building material creates good vapor barrier and protection from extraneous noise, it is used for outdoor finishing work.

- Knauf. A universal product approved for use on any surface. Even concrete floors are plastered and insulated with such a mixture. The composition can be applied manually or by machine mechanisms to save working time.

conclusions

Although there is some misconception associated with insulating plaster - supposedly it is an excellent sound and noise insulator, which is largely untrue, its use is a significant step forward in the "art" of insulating both the external facades of buildings and the walls inside. Be sure to keep in mind this opportunity to save heat in your home and invite real professionals to do the work.

Observing all the technologies, not forgetting about the finishing and the need to preserve or create the appearance of the wall, the result is simply brilliant. This cannot be achieved with styrofoam

Views

From a technical point of view, the plaster composition has the desired properties due to the fact that it is based on insulating materials.

According to the composition of the mixture, they are divided into three types:

- plaster mass on a vermiculite basis. The additive is produced using thermally treated rock of mountain origin. Expanded vermiculite has antiseptic properties, protects walls from fungal formations. The mineral is light, it is poured into ready-made dry compositions;

- mixture with expanded polystyrene granules. Excellent material for storing heat energy. The composition contains cement and lime, filling components and special additives. Suitable for all surfaces;

- sawdust plaster. It is not able to withstand the effects of a humid environment, therefore it is not used for outdoor decoration. When insulating the inner walls with this composition, please note that during solidification, you should constantly ventilate the room. This type of plaster is applied to wood and brickwork and hardens within two weeks.

Separately, it should be told about the Knauf Grünband heat-insulating plaster composition. This product line is known to many, represents the most popular formulations.

Fractions of the mixture do not exceed one and a half millimeters in diameter, application is possible manually and using electrical equipment.

This mixture is used for finishing facades, basements, and other rooms with a high moisture content. In addition, with the help of plaster, the facade surface is strengthened, the walls receive additional protection from mechanical damage, the formation of cracks is completely excluded. The structure of the plaster mortar is such that it can be used for decorative finishing.

Dignity

- speed of the process;

- no need to use reinforcing mesh;

- no wall alignment required;

- no need to use additional bridges;

- after finishing, no living creatures, including rodents, will be able to settle in the walls.

But, like all materials, this type of building facade decoration has its drawbacks. Someone strongly draws attention to them, while others do not.

- It is better to apply an additional decorative layer.

- The insulation layer is thick enough.

There are several types of plaster, it all depends on which surfaces you want to apply it to. So for walls made of ceramic blocks, you can use the following types of plaster:

- Traditional facade decoration with brickwork.

- Simple - perhaps the simplest and cheapest processing method.

- Ventilated facades are a fairly new method for finishing ceramic block facades.

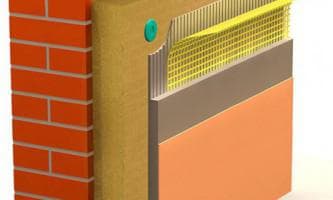

- Insulation - an insulating layer is used here, which can be attached to the wall. An additional layer of plaster is applied on top.

It will be interesting to find out from the article what kind of plaster can and should be used for pinoplex when decorating a house or room.

In the video, warm plaster for outdoor use:

What properties do these or those fill in the composition of warm plaster exhibit?

- Wood sawdust is the simplest type of filler and the cheapest. And with all this, the least effective material. Sawdust plaster can be prepared even at home.

- Expanded polystyrene - also belongs to the class of inexpensive materials, but has one rather significant drawback. This material is flammable. Such a filler is used much less frequently than all other types.

- Perlite is also produced by volcanic glass. Obsidian swells under the action of a high temperature of 110 degrees, resulting in bubbles. A significant drawback is the ability to absorb moisture. Plaster, which contains this filler, needs a protective layer.

- Foam glass is quartz sand, which is also foamed. Glass bubbles are non-flammable and waterproof. As a result, it is the perfect filler. For facade work, this type of plaster will be the best option.

When choosing one or another type of plaster, you need to pay close attention not only to the price, but also to the composition. After buying cheap plaster, you can condemn yourself to the purchase of additional accompanying materials, which will only increase the total cost of insulating the facade of the building.

Also read how to make textured plaster from ordinary plaster.

Advantages and disadvantages

The main advantages are:

- resistance to wear, no deformation changes;

- high strength indicator;

- the absence of components in the raw material that pose a danger to human health;

- resistance to negative temperature conditions;

- high adhesion qualities;

- the ability to use on any type of surface;

- reinforcement is not required in most cases.

Unfortunately, there are also negative aspects:

- the thermal insulating ability of such a composition is much lower than that of classic insulation materials. To achieve a similar indicator, it will be necessary to arrange a plaster layer, one and a half to two times in thickness exceeding the usual heat-insulating layer;

- the mixture is rarely used as a finish. After drying, it requires final processing with materials that are more suitable in their composition than others.

Warm indoor plaster mix is not ideal. Like other goods, it differs in its positive and negative properties.

Description

What are the ingredients in warm plaster?

- A filler is a substance that helps to increase the vapor permeability of the entire plaster layer.

- A plasticizer is a component that gives good elasticity to the plaster.

- Water repellent - allows the plaster to be resistant to moisture.

- White Portland cement or a mixture of lime and gypsum is used as a binder.

There is also structural plaster for interior work, more details about which can be found here from the article.

In the video, warm plaster for the facade:

What are the advantages of warm plaster? In addition to the fact that it exhibits high thermal insulation properties, it also has a number of other advantages:

- It is lightweight. Unlike conventional plaster, its specific gravity is on average 300 kg / m3 after the setting process.

- The layer remains solid. Even if there is an impact of external factors, such as wind, water, dry air, cracks will not appear, the top layer will not fall off and other similar phenomena will not occur.

- Good adhesion properties. This makes it well suited for all types of substrates. If the layer thickness exceeds 5 cm, then you need to use a primer and reinforcing fiberglass.

- Amenable to restoration. If any mechanical damage has occurred, then they can be easily repaired. In this case, you do not have to completely remove the entire layer of plaster.

- Convenient to use. For warm plaster, you do not need to purchase a lot of tools. You just need to have a spatula, grater and trowel.

- Safety.This property indicates that it is made from environmentally friendly materials. Therefore, its use is not limited when processing facades. It is also used for work inside the house.

- Finishing finish. Such plaster is used as the last layer for finishing. If you add a vapor-permeable coloring agent to the composition, then you can achieve the desired color.

Find out about decorative plaster for interior wall decoration here.

In the video - warm plaster for outdoor use:

How to make the mixture yourself

You can prepare a plaster for insulation with your own hands by purchasing all the materials necessary for this on the construction market. So, we need cement, a material with a porous structure, plasticizers.

The porosity of the components allows the plaster mixture to perform insulation functions, gives it vapor-permeable properties, giving the walls the ability to "breathe". Mold does not form on such materials, because there is no main source for this - dampness.

The use of plasticizers for the cement base gives the mixture good plasticity and ensures adhesion to supporting bases.

For this reason, thermal insulating plaster compounds differ in characteristics that allow them to be used on concrete, wood, brick and even ceramic surfaces.

Technologically, the process of preparing a plaster mixture looks like this:

- one share of M500 grade cement is taken;

- four parts of perlite grains or vermiculite are poured;

- water is poured in such a way that the mixture gets a consistency resembling sour cream;

- plasticizers are taken at the rate of 50 g for each bucket of cement.

Plasticizers are diluted in water, the cement is thoroughly mixed with the granules. Water is poured into the dry mixture, mixing is carried out until the required plasticity. The solution settles for fifteen minutes, after which it is completely ready for use.

Do-it-yourself plaster mix will cost you much less.