Dry insulation is a guarantee of 100% protection against heat leakage. Due to natural diffusion, moisture vapors move from the walls of the house, which normally evaporate from the surface. And if the house is insulated and the thermal insulation is closed with dense materials, the movement of flows is disrupted. As a result, the thermal insulation can get wet and lose its insulating properties. How to make the evaporated moisture leave the insulation freely, let's figure it out together!

What are the types of external insulation with a ventilated gap?

Thermal insulation materials are always covered with decorative trim or external cladding of panels and slabs. The finishing layer performs not only a decorative function, but also protects the insulation from getting wet, weathering and damage. Most often, there are two systems of external thermal insulation, for which an air gap is structurally necessary:

- Ventilated facade systems;

- Brick cladding.

Both systems are different from each other in the way of the device, the composition of the structure and the external finish, therefore the approach to the ventilation device is different. For the installation of a hinged ventilated facade, our experts recommend:

| Rockwool LIGHT BATTS SCANDIC | Basvul VentFacade | Rockwool Venti BATTS |

How to insulate a brick house from the outside?

When installing inter-wall thermal insulation, there must be a ventilation gap between the insulation and the brickwork.

If we are talking about insulation outside, then it can be done in three ways. You can make "wet" insulation, insulation between walls or make a ventilated facade.

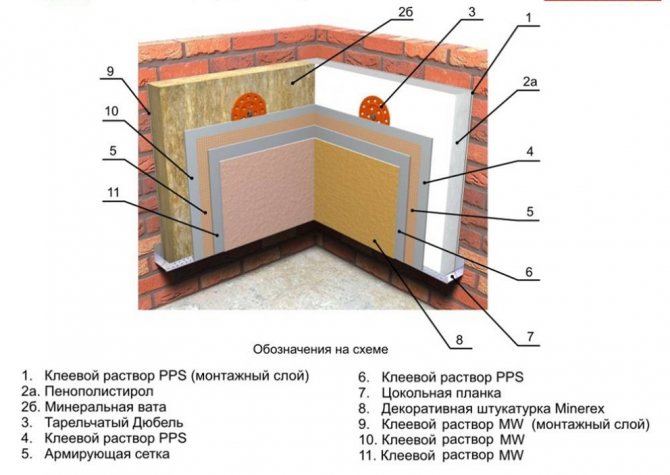

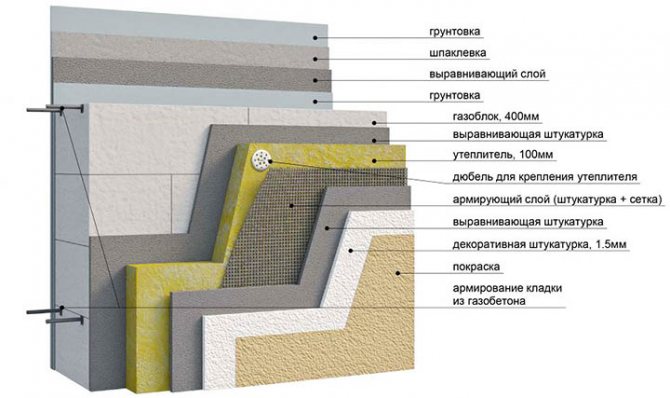

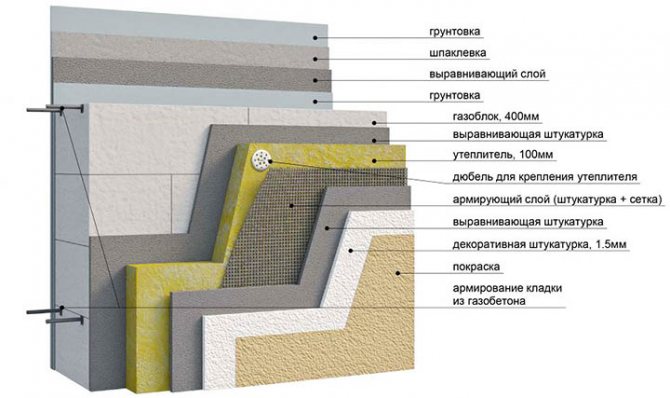

If "wet" insulation is chosen, then the walls of the room must be covered with plaster, which is made of cement and lime. Then the brick wall surface is covered with a primer and an adhesive, on which the heat insulator is installed, then the heat insulator is additionally reinforced with dowels. Then you need to proceed to the reinforcement, which consists of the next application of a layer of adhesive solution and the subsequent installation of a special mesh. An initial layer of plaster should be laid on such a surface. Upon completion of the work, all this needs to be given a decorative look, this is done by means of plaster, but of a different type.

If we are talking about small brick buildings, then you can choose an inter-wall thermal protection, while the configuration of the wall structure should not differ in complexity. The outer wall is the outer sheathing structure, and the inner wall must be plastered. In this case, mineral wool is best suited as a heat-insulating material. With this procedure, it is imperative to provide a ventilation gap and make additional brickwork with a width of about 12 cm. The outer and inner walls must be connected with mortgage anchors.

When choosing a ventilated facade, the layers of the "cake" should be positioned as follows: interior plaster, outer wall surface, steam insulation, insulation, building membrane, wooden frame, ventilation gap, outer skin. If done correctly, the house will be warm and cozy.

Canadian technology is one of the most popular methods for building a frame house. In our review, we highlighted the most key points, including the rules for constructing a frame system, on the characteristics of which the effectiveness of insulation and the ease of finishing the facade depend.

How to provide ventilation in the space under the cladding?

When facing a wall made of foam or aerated concrete blocks with a facing brick, a wall is formed on the outside that allows water vapor to pass through much worse than blocks of aerated concrete. In these cases, a ventilated air gap is arranged in the walls, located closer to the outer part of the wall between the cladding or protective wall and the cold surface of the insulation.

- Ventilation of the air gap is carried out through special vents made in the lower and upper parts of the wall, through which vaporous moisture is removed to the outside. Recommended area of ventilation openings is 75 cm2 per 20 m2 of wall surface.

- The upper ventilation ducts are located at the cornices, the lower ones at the plinths. In this case, the lower holes are intended not only for ventilation, but also for water drainage.

- For ventilation of the layer in the lower part of the wall, a slotted brick is installed, placed on the edge, or in the lower part of the wall, brick or blocks are laid not close to each other, and not at some distance from each other, and the resulting gap is not filled with masonry mortar.

How to properly insulate a brick house?

The choice of heat-insulating material for house insulation should be based on the climatic zone of construction.

To insulate the house, you can use the services of a professional team, but you can do everything yourself, which will significantly save money. And you need to know that the efficiency of work is in direct proportion to how the established technologies are observed. Of course, it will be better if you have at least initial professional skills when you insulate a brick house yourself.

There are two insulation methods - external and internal, both of these methods imply that the wall surface acquires the properties of thermal conductivity of a structure with a thickness of 2 meters. Many experts do not advise isolating the structure from the inside, but if there is no other possibility, then this option is acceptable.

There are many materials for thermal protection, and each of them has its own advantages and disadvantages. So, some masters prefer foam, which really has excellent qualities for insulation, others choose mineral wool. It is necessary to choose the kind of material that is best suited for solving current problems, while taking into account the following. Insulation material must be selected based on its thermal conductivity and density, which is best suited for the climatic conditions where the house is being built. When choosing an insulation material, it is necessary to take into account such factors as financial capabilities and the planned time for carrying out all construction work. The fact is that not all insulating materials can quickly create the required system, which is not always justified.

After the insulation material is selected, everything should be done correctly. There are many methods for insulating a brick house, the most common are four. Everything can be compared with a multi-layer cake, at least the cooking method is very similar - the first layer is put first, then the second, then the third is laid, and so on according to a similar principle. This principle also applies to thermal insulation.

Table: Comparison of the properties of popular heaters for a ventilated facade

| Parameter | VENTY BATTS | VENTY BATTS D | Value |

| Density | 90 kg / m3 | Top layer 90 kg / m3 Bottom layer 45 kg / m3 | 37 kg / m3 |

| Thermal conductivity | λ10 = 0.034 W / (m K) λ25 = 0.036 W / (m K) λA = 0.042 W / (m K) λB = 0.045 W / (m K) | λ10 = 0.035 W / (m K) λ25 = 0.037 W / (m K) λA = 0.038 W / (m K) λB = 0.040 W / (m K) | λ10 = 0.036 W / (m K) λ25 = 0.037 W / (m K) λA = 0.039 W / (m K) λB = 0.041 W / (m K) |

| Flammability group valve butts | NG | NG | NG |

| Tensile strength for separation of layers, not less | 4 kPa | 4 kPa | 6 kPa |

| Water absorption at full immersion, no more | 1.5% by volume | 1.0% by volume | 1.0 kg / m2 |

| Water vapor permeability, not less | μ = 0.30 mg / (m h Pa) | KM0 | KM0 |

Frame wall with OSB board

OSB sheets are used to make the erected structure more rigid and stable. Installed as a base for further finishing, as well as an additional sound insulator and insulation.

In the event that a frame structure is planned for technical purposes, the insulation material between the base pillars may not be laid

The device of the pie in this case is no different from the previous options. The only thing is that the insulation itself can be chosen differently, for example, polyurethane foam or foam.

Finnish frame wall construction

Assembling the frame wall using Finnish technology

What is Finnish technology and how does it differ from other frame construction methods? When erecting frame houses, there are two main technologies - Canadian and Finnish (Scandinavian). The main difference between them is that the first option implies the preparation of structural elements directly at the installation site, and in the second case, most of the structural elements are manufactured in the factory and arrive at the construction site already ready-made.

The final stage is external and internal decorative finishing.

The order of work when assembling walls in the Scandinavian way:

- A timber frame is mounted on the strip foundation and the lower overlap is assembled.

- The panels are assembled from factory blanks.

- The assembled panels are installed on a prepared base and connected to each other with metal brackets.

- Any selected insulation, OSB and vapor barrier are mounted.

- The subfloor is laid on the floor.

- Beams of interfloor floors are installed.

- On the ceilings, panels of the walls of the attic or second floor are assembled and installed.

- The roof frame is being mounted.

- The roof is insulated and the roof is installed.

How to equip a ventilated layer in facade insulation?

If the outer cladding is made of dense vapor-tight sheets, then a ventilated air gap is arranged in the wall. The thickness of the ventilation gap is 60 mm, this is the distance between the outer skin and the insulation boards. Vapor-permeable mineral wool must be covered with a windproof vapor-release membrane.

One of the options for decorating the walls of low-rise buildings is to install a siding protective screen. These thin profiled "boards" are made from metal (metal siding) or PVC (vinyl siding, plastic paneling).

Decorative siding panels can imitate wood planks, masonry, etc. A ventilated air gap is provided between the decorative siding screen.

- When installing siding, vertical guides with a step of 600 mm are attached to the existing frame or wall: from wooden slats 4x6 cm, 5x5 cm, special profiled strips made of PVC or galvanized steel.

- The guides are installed strictly vertically. If the walls are uneven, they are leveled with wood, plywood spacers or the size of the slats is reduced.

- The space between the rails is filled with rockwool LITE BATTS® or Venti Butts thermal insulation boards. If the required thickness of the insulation layer is greater than the thickness of the slats, then they are installed in 2 rows - horizontally and vertically.

- The slats and insulation should be installed so that an air gap remains between the surfaces of the insulation and siding.

To ventilate the air gap and remove diffusion moisture, there are special ventilation holes in the lower edges of the siding panels through which vaporous moisture is removed to the outside.

Note! From the outside, light butts stone wool insulation should be protected with a windproof vapor-permeable material. Siding panels are installed taking into account possible temperature deformations. Therefore, when installing the siding, strengthening the panels to the chamfers and edges, they leave a gap in the winter - 10 mm, in the summer - 6 mm.

Materials used

Consider what the walls of frame houses are made of. The material is chosen not only for aesthetic indicators, but also for its ability to withstand certain loads imposed on it.

An example of a frame house with an exterior finish in the form of decorative plaster

Basic set:

- Square beam made of pine needles, maple or other hardwoods with a moisture level of 11-12%. The optimum material thickness is 150x200 or 200x200 mm.

- Planks of larch or other coniferous trees with a section of 150x50 mm.

- I-beam made of two beams with a lintel made of OSB slabs. It is necessary to adjust the shelves depending on the chosen insulation and the size of the base. The use of an I-beam significantly increases the thermal insulation properties of the walls and reduces the risk of deformation of the battens when the house shrinks.

- Wall decoration for outdoor and indoor use. The materials in this category include both composite panels based on plywood or OSB, and standard boards or boards. Glass magnesite is also used. Materials for in-wall decoration must be thoroughly dried, treated with antiseptics and have no defects.

- Heat insulator of soft or hard type. Most often, when erecting frame walls, basalt or mineral wool, polystyrene or extruded polystyrene foam, sprayed insulation are used.

- Wind-, moisture-proof and vapor-proof multifunctional membranes that help remove moisture from the inside of the walls and do not let it back through. An additional function of the film is to protect the building from moisture and blowing.

- Materials for decorative finishing. For exterior design, metal or vinyl siding, edged board with imitation of a bar, block house, artificial stone, acrylic or decorative plaster can be used.

Frame wall made of metal profiles in combination with foam concrete blocks

In some cases, for the construction of walls of a frame structure, a galvanized or aluminum profile is used in combination with foam concrete or its foamed analogue. This approach allows you to build a more reliable structure in the shortest possible time.

Waterproof and vapor barrier membranes, as well as materials for wind protection, are films that differ from traditional polyethylene with an internal porous structure. The structure of such a film allows moisture to seep in only one direction, blocking all return paths. Foil material can be used to protect against moisture. Such a film is vapor-tight and can withstand high temperatures. It is advisable to use it in places where heating and heating devices are installed.

Video - Overview of heaters for a frame house

What are the heaters

To begin with, consider the positions that can be used to insulate the ceiling in a private house with your own hands.

Mineral wool blocks and mats

The materials are mixtures of natural mineral fibers and resins. Sold in hard slabs and soft roll mats. They have a low coefficient of thermal conductivity due to multiple air gaps in the material array. Samples of this category are the most popular and deserve the attention of those who first thought of making ceiling insulation in a private house with their own hands.

Other advantages include

- low specific gravity (lightness),

- fire resistance,

- vapor permeability,

- materials do not rot,

- insects do not start in them.

In a stationary state, the mineral wool is safe, but during operation it forms dust, therefore it requires personal protective equipment (overalls, gloves, glasses, respirator).

Slag made from a by-product of metallurgical production - modified blast furnace slag. The representative of the wadded family is especially popular with newcomers to the repair business because of the low price.

If you are doing ceiling insulation in a private house with your own hands for the first time, attention!

The material has a significant drawback - it actively absorbs moisture. Slag wool is effective only with absolute observance of the rules of laying and hydro-vapor barrier, otherwise it gets wet and becomes a useless element with negligible insulating properties.

Basalt (stone) wool consists of molten lava fibers. As a native of nature, ecologically safe, as a product of volcanic activity, resistant to high temperatures, as a heat insulator, recommended for use in the Far North.

Plus to everything

- does not get wet due to oil impregnation,

- does not lose thermal insulation properties when compressed,

- durable.

Foil samples, due to the reflective metal surface, have improved heat-saving properties.

Polymer heaters

Eextruded penopolystyrene (a modern type of foam) will reliably protect the roof from the cold for a hundred years. The sintered polymer granules form a strong honeycomb-like structure. The boards do not shrink, do not get wet, are easily attached with glue, their grooved joints do not need to be sealed.

Insulation is not recommended for internal insulation of wooden ceilings, since it does not allow air to pass through at all.

The flammability of the material is low, it slowly melts, but it emits poisonous smoke and this is its second drawback.

Granular foam - the best solution for heated rooms. Five centimeters (required thickness) - sensitive, but not critical for low ceilings. Plates are easily attached on PVA to any filing material (plasterboard, plywood).

The disadvantages are

- flammability,

- fragility

- combustion toxicity,

- can become a breeding ground for rodents.

From sudden temperature changes, the foam turns into crumbs, therefore it is not suitable for external insulation.

Sprayed heat insulators

The main advantage of the sprayed samples is the absence of seams (they let the cold pass). The material lays down with a light monolithic absorbent blanket, completely covering the insulation zone.

Ecowool - cellulose insulation, waste paper processing product.

With a comparable thermal conductivity with mineral wool, it is one third more expensive than the latter.

Dry ecowool is suitable for insulating open horizontal ceilings (attic floor), moistened with water with the addition of glue, firmly adheres to vertical and inclined surfaces (roof).

You can apply liquid material on your own using a blowing machine (rent or buy), you cannot do without it when processing hard-to-reach areas.

There are restrictions: when applying wet, the working area must be warm (above + 23 °) and dry (humidity no more than 70%) - after processing, the material must dry.

Question: what is the best way to insulate the ceiling of a private house? will sound rhetorical if you do not specify from which side you will have to do this.

Properties and characteristics of foam

Polyfoam consists of 98% air, the rest is thin-walled balls of expanded polystyrene. The list of positive properties of polystyrene is extensive, analogs to the material in terms of the sum of positive properties are extremely difficult to choose:

- Easy to handle by hand with a knife or saw;

- Fastened in any available way;

- Adheres to any material;

- Resistant to aggressive solutions;

- Inert to building materials of mineral origin;

- The use in insulation allows you to exclude the device of a vapor barrier;

- Does not add loads to the foundation of the frame structure;

- Possesses excellent soundproofing performance;

- Significantly reduces the cost of insulation in comparison with other insulation materials;

- Allows to reduce the total amount of consumed energy resources and reduce the amount of equipment for heating the house;

- Allows a reduction in wall thickness.

Insulation of aerated concrete house. Basic principles

The main feature of aerated concrete block is high moisture permeability. If you do not provide it with proper protection from water and moisture, then this will invariably affect the parameters of its thermal insulation. And it doesn't matter what kind of insulation was used. Therefore, the first thing to think about when building a house from aerated concrete is its protection from the environment.

For this purpose, it is recommended to treat aerated concrete walls with moisture-proof impregnations - this is the so-called process of hydrophobization of concrete walls.

Due to the high moisture permeability of aerated concrete, many developers prefer to insulate such houses externally, placing insulation on the facade of the building and covering it with facade panels, plaster, stone or other facade materials. Although, as practice shows, effective insulation of a cottage from aerated concrete can be equipped both on the facade of knowledge and inside the premises.

As a rule, aerated concrete insulation scheme is as follows:

As you can see, this is a whole "pie" of various materials.

Heaters must also be protected from moisture. To do this, you need to use a vapor-proof material that will help to avoid the formation of condensation on the walls. For this reason, many experienced developers prefer to cover the walls with a vapor-permeable film.

An effective insulating layer will not only help keep warm, but also increase the soundproofing qualities of the walls and give the house a well-groomed and cozy look. Due to the fact that aerated concrete is a porous material, well-carried out insulation will help keep warm inside the room even in very cold winters.

How is the insulation of aerated concrete with plaster done?

Another way to insulate aerated concrete walls is to plaster them. For this purpose, you can use special facade plasters, it is enough to apply a layer of 3 cm.

In addition, to insulate an aerated concrete cottage, you can use simpler plaster, prepared on slag sand. However, the last layer must necessarily be moisture-resistant and heat-resistant plaster. This will make the surface of the walls more protected and smooth, and due to the presence of polymers in the composition, such a facade will be highly resistant to any temperature extremes.

Given the large area of work, it is best to plaster aerated concrete by machine:

For the insulation of walls made of aerated concrete, extremely light plaster mixtures are used. Before starting the wall insulation, it is necessary to thoroughly clean and work out the interblock seams with a metal spatula so that grooves form in them. Thanks to this, the adhesion of the plaster to the wall will be more reliable.