Types of drywall and its application

Drywall can be used to insulate walls inside a building. Use either moisture resistant or wall.

Moisture resistant can be used in summer cottages or for rooms with a high degree of humidity: bathrooms and kitchens.

Important! Moisture-resistant drywall, the best solution for rooms where heating is not provided.

This material is not threatened by cyclical jumps in temperature. It is only necessary after mounting the sheets to apply a waterproof primer or protective paint to the front part. You should also do the treatment of drywall with an antiseptic, which allows you to kill harmful microbes and bacteria.

Wall types are suitable for living rooms where the humidity is no more than 70%. Sheets are marked in blue on a gray surface.

As for the size of the sheets, it is best to purchase products 2.5-3 meters long and 1.2 wide. In terms of thickness, 12.5 mm canvases are perfect (9.5 mm is the ceiling view).

- normal;

- moisture resistant;

- moisture and windproof;

- reinforced strength;

- fire resistant.

Frame method of insulation

There are 3 methods of insulation:

- Glue method. Sheets are attached directly to the wall using gypsum or polymer-cement glue. With this finish, the area of the room does not become smaller. The only drawback of this method is that it is impossible to make a laying of thermal insulation, and the walls must be strong.

- Frame method with a thermal insulator.

- Frame method without insulation.

The last two methods of installing drywall are used most often. In order not only to insulate the room, but also to achieve good sound insulation performance, you will need to use a profile. The only drawback is that the room is significantly reduced in size.

Why drywall?

Insulation of walls with plasterboard from the inside allows not only to insulate the room, but also to level the surface of the walls. This issue can be solved immediately by using only one material - drywall, because it is excellent for both insulation and sound insulation.

Plasterboard sheets leave space between the wall itself and the gypsum board, which makes it possible to enhance the effect with the help of insulation.

This method of warming is considered optimal, because all the work can be done independently, efficiently and quickly. At the same time, special glue can be used for fastening the gypsum board (optimally with slight irregularities in the walls), it is also recommended to use a metal frame during repairs, this will allow the heat to stay indoors longer.

It is possible to list the characteristics of drywall for a long time, we will write out those of them that relate to insulation:

- GKL sheets have a thermal conductivity coefficient of 0.15 - this is a fairly low indicator, which indicates a good ability to heat insulation (the lower it is, the better the material retains heat);

- gypsum plasterboard is able to improve the microclimate in the house, which will ensure the preservation of heat in winter and will not let the heat in summer.

Insulation types

Warming the surface under the drywall is best done with mineral wool or foam. You can also use Isolone or Penoplex. These insulators differ in installation methods, cost, strength.

Studies have shown that styrofoam and polystyrene are unhealthy. In residential premises, it is rarely used. Another disadvantage is that some types of foam are eaten by rodents. But it has a low cost, and is also available in many densities and sizes.

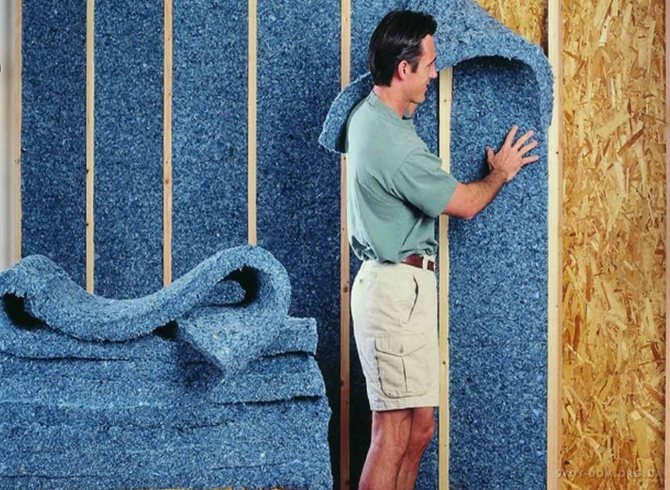

An example of insulation with plasterboard and mineral wool

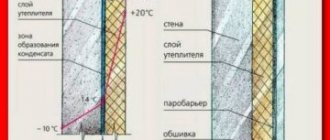

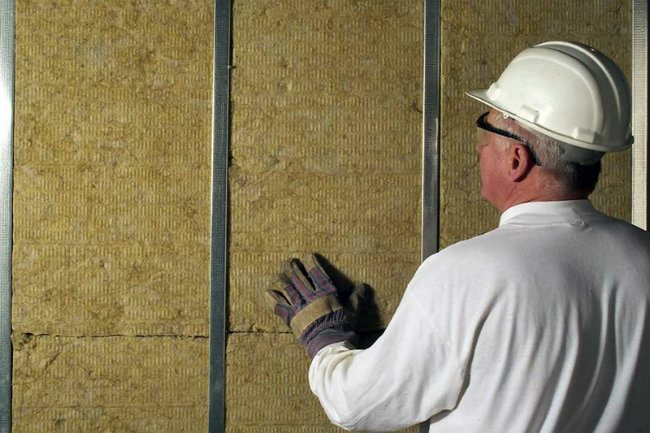

As for mineral wool, the advantages include low weight (especially important for insulating old buildings), as well as low thermal conductivity. There is only one significant minus of mineral wool - hygroscopicity. Therefore, when insulating partitions and walls, it is necessary to prevent the accumulation of condensation. For this, steam insulation should be used.

There are several types of mineral wool. All of them differ between the method of production, composition and technical indicators. Among the types of wool on the market, the most popular is fiberglass-based basalt wool. Like other types of insulation, they have both advantages and disadvantages.

The main negative sides of glass wool:

- The indicator of thermal conductivity is higher than that of stone, respectively, heat disappears faster.

- At elevated temperatures, it forms a solid glass mass.

- It is inconvenient when working (glass wool fibers can cause itching, requires the use of protective glasses, gloves, a respirator, wearing a tight suit).

Important! For greater efficiency, it is necessary to lay mineral wool in 2-3 layers.

Despite the external similarity, basalt and glass wool differ significantly. Glass wool is made from very thin fiberglass, while basalt wool is made from volcanic rock. They also differ by an indicator of thermal conductivity, which is less in basalt, and, therefore, it retains heat better.

The cost of materials for insulation:

- The cheapest way would be to insulate the walls of the house with polystyrene, the price of which ranges from 70-90 rubles. for 1 sq. m.

- As for mineral wool, it costs a little more - 90-150 rubles. The price of the material depends on its density, thickness and manufacturer.

- Penoplex, which is extruded foam, but with increased strength and density, costs 1 sq. meter about 200 rubles.

Isolon (foamed polyethylene) can also serve as an insulator. Its cost will be 280-300 rubles per 1 square meter.

Insulation for partitions

Can I apply as insulation for partitions in a wooden house Styrofoam? Yes, but with some degree of convention. Despite the inclusion of non-flammable components in its composition, the non-flammability of the material leaves much to be desired.

And outwardly, the foam is normal and the one that passed the combustion test is no different. When buying, you will have to believe the documents accompanying the consignment of goods, or use it inside not wooden, but concrete structures, where the likelihood of a fire is lower. Partitions from gypsum boards have gained demand due to the ease of installation and low costs of purchasing the necessary building materials. Drywall sheets themselves are considered a good insulation and sound absorber, the air gap between them enhances the effect. Sometimes insulation for partitions from hl do not insert inside - it all depends on the requirements for the building.

However, this approach is more the exception than the rule. No one asks why to insulate the outer walls of the house, ceilings, floor, roof, but about insulation for partitions you can hear conflicting opinions. Some say that it is not needed, because the heating system is uniform, and it makes no sense to isolate one heated room from another. There is a reason in such reasoning, but there are many who want to insulate, for example, a nursery or a bedroom, at the same time adding several additional sections to the battery. It is more rational to insulate partitions with basalt or fiberglass sheet mineral wool with a density of 35 kg / m³ and a thickness of 50 mm - TECHNONICOL, ROCKWOOL, ISOVER, etc.

For example: TECHNONICOL Rocklight, TECHNONICOL Technolight optima, TECHNONICOL Technolight extra, ROCKWOOL Superrock, ROCKWOOL Rokmin, ISOVER KL 37. For partitions, it is recommended to take a profile of 50 x 50 mm, 3 m long, along the perimeter - a profile of 50 x 40 mm. Lay a layer of vapor barrier on both sides of the mineral wool insulation in the frame partition.

And yet, foam is an excellent budget solution for sound and thermal insulation of partitions. To increase fire safety (by the way, the foam does not burn, but melts), you can glue the facade mesh onto the foam sheets and coat it with a tile adhesive solution on top. Styrofoam - popular insulation for partitions in a frame house (due to the cheapness), but here another trouble awaits: if mice get into the foam core, it will be difficult to drive them out.

Stages of thermal insulation of a wall

In order for the work process to proceed quickly and properly, the necessary tools should be prepared. This will significantly speed up the work on protecting the walls with insulation.

The following materials will be required:

- drywall sheets;

- self-adhesive tape;

- insulation;

- membrane to ensure the maximum degree of vapor barrier;

- screws, nails;

- hammer, screwdriver, hacksaw;

- yardstick;

- metal profiles or wooden slats for the construction of the frame;

- fastening materials.

1 sheet requires about 30 pieces of self-tapping screws. It is best to buy screws with a length of 20 mm.

As for the manufacture of the frame, the profile must be taken in 2 types: with the CD and UD markings. The length is chosen based on the size of the room.

Frame design

It consists in tracing the perimeter and thinking over how the frame will be located on the wall. A simple pencil and a building level are enough.

Advice! For the best insulating effect, the structure must be positioned 3-10 cm from the wall.

- surface cleaning;

- even out all irregularities and putty chips and grooves;

- drying with a heater or stroyfen;

- getting rid of mold and mildew.

Sometimes it is necessary to treat the walls with a special waterproofing putty to prevent dampness. First, the layer is applied vertically, then horizontally.

Frame construction

According to the pre-made marks, you need to mount the frame. To avoid contact of the metal structure with the wall, a tape prepared in advance is glued to the profile sole. Fastening of frame parts to the wall is carried out using self-tapping screws and dowels.

Before laying the insulator, the surface is prepared in advance. Remove or restore fragile plaster areas. To exclude the possibility of mold and mildew formation, it is necessary to do the treatment with a primer with an antiseptic.

Plasterboard sheets are installed on a frame made of metal profiles or wood. A metal frame will serve significantly longer than a bar.

In the area where the batteries are located, where the installation of thermal insulation is difficult, penofol can be used.

For drywall, you can make a frame from bars

Assembling the frame begins with the installation of the guides created from the UD profile. The slats are attached to the ceiling and floor with an indent from the walls of 50-60 mm. The section of the rack profile is inserted into the guides. The ends are fixed with small self-tapping screws ("flea beetles"). The edges of the suspensions are bent from the sides and connected to the slats. The step between the profiles must be observed so that there are 3-4 slats per sheet.

Important! When the frame is constructed, the insulator begins to be laid.

To improve the rigidity of the structure, it is necessary to make transverse jumpers from the CD profile. The profile is cut in such a way that its length overlaps the adjacent strips by half. Shears are cut off the shelves with metal scissors. Then the workpieces are fixed with “flea beetles” on the frame.

Balcony wall insulation

As for the insulation of balconies and loggias, such structures require compliance with certain rules.

The material for thermal insulation should be:

- waterproof (since there is a high probability of water appearing on the balcony);

- drywall you need to buy only moisture resistant;

- walls should be treated with an antiseptic.

For the insulation of balconies, a frameless method is often used. This is due to the fact that such a space has a small area. The insulator creates a higher degree of structural reliability despite different influences: tension, moisture and other loads.

Initially, the walls are prepared for fastening the sheets. All fragile areas are restored, and the surface is treated with an antiseptic agent.

As soon as the walls are prepared, they begin to install the sheets. Initially, they need to be cut into the required pieces. It is not recommended to cut the sheets right away, it is better to do this in the process of work.

Once the material is prepared, you can start fixing it. This should be done using an adhesive. This is the easiest way to attach hl. When carrying out such work, you need to ensure that the layer of the mixture is the same everywhere.

Thermal insulation allows you to protect the house from dampness, drafts and provide a favorable and comfortable microclimate. After all, a heater, like a shield, can be fenced off from the harmful effects of the environment.

Posted on 03.07.2016 in category Building materials // 0 comments // Posted by Admin

- 5

- 4

- 3

- 2

- 1

(1 vote, average: 5 out of 5)

Plasterboard is a modern building material for interior decoration. For several years, he gained immense popularity among both builders and ordinary people.

Advantages of drywall

Drywall, unlike brick or foam block, does not limit the imagination of designers in anything, and anyone who knows how to hold the simplest tools in their hands can handle the installation of a drywall partition. Plasterboard partitions are lightweight, so they do not create a tangible load on the floors and the building structure itself.

Drywall sheets themselves have excellent sound and heat insulation properties, and the empty space between them further enhances this effect. Therefore, if you revet the walls facing the street with plasterboard, this will make it possible not only to prevent the cold from getting into the room in winter, but also prevent the heat from penetrating inside from the walls heated by the scorching sun. In this case, it is advisable to mount the sheets on a metal frame, not immediately on the wall. The space between the drywall and the wall provides additional thermal insulation.

Insulation materials

Installation of insulation

Isolation stages

First you need to clean the wall. At the same time, do not heed only the advice: cleaning-drying-washing. This, of course, is hassle-free, but, unfortunately, not everything. The more carefully the work surface is prepared, the better the result will be.

Make sure that no moisture gets on the wall. It is this factor that will allow you not to worry about the condition of the base under the insulation for a fairly decent time.

After cleaning, saturate the walls with antiseptics or fire retardants - special impregnating solutions. (With wood, such work must be done!)

The wall must be leveled if it has significant bumps, and also pay attention so that there are no cracks or cracks. Because all this will allow heat to pass through, preventing the insulation from performing its task.

Frame construction

A variety of thermal insulation materials can be glued in place. However, do not forget that you still need to mount the outer sheets. Therefore, for this you need to make a supporting frame, on the rails of which you can then fix the drywall itself.

Traditionally, the frame is mounted from wood, however, in my opinion, there are two significant drawbacks here:

- The weight of the designed frame can be quite decent. Provided that the walls are made of aerated concrete, there may be serious difficulties with fastening.

- The frame is made taking into account the technical indicators of the selected insulation. The design is again extremely heavy and only adds to the problem.

Therefore, experts advise buying profiles specifically for laying under drywall, this will save time and effort. The best option is galvanized. Profiles from this material can even be cut with scissors.

When attaching profiles, you need to look at the dimensions of the drywall sheets. The profiles themselves can be mounted both horizontally and vertically. Before laying the profiles, you need to stick a special tape on the frame. This will have a good effect on the sealing of the joints, reduce heat transfer and can help to avoid deformation of the battens.

You need to control the alignment vertically and horizontally, this will guarantee a flat surface.

Insulation laying

When you already have a frame, then you can lay the material in the resulting "cells". The styling details depend on the type of insulation you have chosen. If you are working with foam, then do not forget about fixing with dowels.

Important! All joints must be sealed! The joints of the slabs are glued with construction tape, and between the slabs and the ceiling, they should be treated with construction sealant.

At this stage, I would advise you to watch a video that will bring specifics specifically for your material.

Laying vapor barrier material

Vapor barrier material protects against moisture accumulation in unnecessary places. Usually a vapor barrier is a film on which foil pollination is applied. The shiny side should face the inner wall of the apartment. The vapor barrier sheets must be overlapped. For a greater guarantee, glue the joints with metallized tape.

Plasterboard sheathing

After the stage of laying the vapor barrier is completed, you can proceed to the plasterboard cladding. It is made with self-tapping screws. The joints of the sheets must be puttied, after which they must be sanded and covered with some kind of paint and varnish composition, or a tape must be glued. This will help avoid cracking of the putty.

A few recommendations so that you have an idea of some of the nuances.

- When choosing insulation for drywall, be sure to pay attention to their dimensions, so as not to waste time, once again cutting and adjusting something.

- There should be as few joints as possible. This will keep the apartment warm.

- Provided that the communication lines pass along the wall, please note that the insulation must be under them.

- In order not to disrupt the natural air circulation in the room, leave a small gap between the frame slats and the insulation.

In conclusion, I will say that wall insulation with plasterboard has many advantages. This is not only keeping your home warm, but also good sound insulation, which is important if you live near a railway, noisy street or tram line. Anyone can make such insulation on their own, it is important to be patient and attentive.

Wall insulation with plasterboard

Installation of drywall sheets is one of the most popular ways to install thermal insulation material. In some situations, 1 layer without additional insulation is sufficient to increase the heat level in the room.

Insulation for GKL partitions does not require special conditions or properties. Drywall has tremendous advantages over other interior decoration methods. It is easy to cut and install, and the thermal insulation is aesthetic and inexpensive.

Material characteristic

Moisture resistant gypsum plasterboard painted green

GKL are produced with a thickness of 12.5 mm for walls and partitions and 9.5 mm for ceiling sheathing. Standard sheet sizes are 2.5 * 1.2 m.According to additional characteristics, the material is divided into:

- regular or standard;

- moisture resistant;

- increased strength;

- fire resistant.

It is still recommended to lay a layer of thermal insulation between the wall and the gypsum board

GKL has a low level of thermal conductivity ten times lower than that of concrete. The value of the indicator ranges from 0.14 to 0.15. It is thanks to this value that the sheets perfectly cope with the task of retaining heat inside the room without the use of an additional layer of insulation.

Nevertheless, thermal insulation is usually laid under the gypsum board with a thermal conductivity value of 0.03. A decrease in thermal conductivity is possible when installing gypsum boards on the frame guides. This design significantly increases the thermal insulation properties of walls and floors.

Wall insulation with plasterboard from the inside is used both in office or utility rooms, and in living rooms. Such insulation is most relevant where it is difficult to arrange the outer layers of thermal insulation, especially in corner rooms.

GKL is often mounted on a metal frame

Experts consider the device of a thermal insulation system from drywall sheets to be one of the simplest and fastest methods. Any technology has its own specifics, wall insulation from the inside with plasterboard is no exception.

Depending on the area of the room and the required level of thermal insulation, you should choose one of the installation methods.

Methods for fixing the installation of gypsum board:

The sheet is glued directly to the wall using gypsum or cement-polymer mortar. With this method, the gypsum board itself is used as a heater. This installation method does not reduce the area of the room. The disadvantage is the inability to lay the thermal insulation material. The wall covering must be absolutely strong without delamination.

GKL sheets are attached to metal guides or a wooden frame beam. The service life of a metal base is much longer than a wooden one. In addition, the tree is prone to deformation, especially in the regime of temperature changes. The air chamber between the wall and the sheet, even without laying the insulation material, provides a good level of thermal insulation

Frame with insulation

With this method of installation, a thermal insulation material is laid in the chamber between the wall and the gypsum board sheets. The height of the guides in this case is equal to the thickness of the insulation material.

Using the frame method with the use of insulation material, the movement of convection air currents is prevented and the level of thermal insulation is increased.

Penoplex insulation under drywall without frame

The step-by-step instructions will be as follows:

- At the first stage, the base surface is prepared: the old coating is removed, cracks and potholes are repaired, protrusions are knocked off. The wall should be as flat as possible.

- The surface is treated with a deep penetration primer.

- According to the manufacturer's recommendations, a special composition is being prepared. If not, you can apply tile adhesive.

- The inner part of the insulation plate is rolled with a needle roller. Another option is to brush it with a metal brush. This will ensure good adhesion to the adhesive solution.

The adhesive is applied to the surface of the sheet with a notched trowel. It is not necessary to cover the entire slab with the composition: it is enough to smear the perimeter and center, the options are shown in the photo.

- A piece of insulation is applied to the wall and held for a minute. Be sure to control the correct installation at the building level.

- They start from the bottom. It is recommended to shift the rows relative to each other so that the slabs are staggered.

For reliability, the penoplex is fixed with disc dowels: 4 are placed at the edges and one in the center.

- Seams between the boards are filled with silicone sealant, wide gaps can be filled with polyurethane foam.

- Drywall is attached to the insulation with. The scheme for applying the composition is the same as for foam plates.It is recommended to place a vapor barrier between them.

- After the glue dries, which takes 24 hours, the drywall is finished. The seams are sealed with putty and serpyanka mesh, rubbed, after which the entire surface is covered with a double layer of primer.

- Vertical elements are mounted. They are screwed to the guides with self-tapping screws for metal. The deflection is adjusted using straight hangers, placed every 50-60 cm. The position of the racks is checked with a building level.

- Penoplex is glued to the wall in the same way as with the frameless method. Insulation plates are rolled with a roller with needles, an adhesive solution is applied. Then they are tightly inserted between the uprights and pressed for 40-60 seconds.

Advice. Pieces of insulation are placed in a metal profile to prevent heat transfer through the racks. Another option is to fill them with foam.

- Drywall sheets, if necessary, are cut into the desired fragments. GKL docking takes place strictly on the racks. The fixation is carried out with self-tapping screws with a pitch of 25-30 cm. In order not to damage the surface of the drywall during installation, a special bit is put on the screwdriver, which limits the screw-in depth of the self-tapping screw. You can find it in hardware stores.

- It is made with reinforcing tape and putty. After grouting, the entire wall is covered with two layers of a special primer on drywall. The second layer is applied after the first has dried.

Thus, it is quite possible to insulate the walls of the apartment from the inside using penoplex and drywall with your own hands. If you do everything correctly and carefully, then the desired effect will certainly be achieved. The process can be seen in detail in the following video. And if you have any questions in the course of work, ask them in the comments.

With the help of room insulation, you can protect your home from dampness, drafts and create a pleasant microclimate. After all, a heater, like a shield, manages to isolate itself from the adverse effects of the external environment.

One of the best ways to save heat is to insulate the walls from the inside with drywall.

Drywall is a material that has indisputable advantages over other finishing methods. It is very easy to use, and the thermal insulation is inexpensive and beautiful.

What is the coefficient of thermal conductivity of drywall? Thermal conductivity is usually understood as the ability of a substance to transfer heat to the coldest areas from the hottest ones. Materials with lower values retain more heat. For drywall, the thermal conductivity value is 0.14 - 0.15. For example, reinforced concrete (the most common partitions in houses) has a high value - at least 1.5. And for various types of insulation, this indicator is five to six times lower than that of drywall.

Wall insulation for drywall is often used both in large office premises and in ordinary apartments, especially corner ones, when external insulation is problematic or expensive.

Insulation material

When installing mineral wool, use a vapor barrier

Internal insulation of drywall partitions is made with various materials. The most common heat insulators for laying under drywall are:

- Mineral wool. The material has a very low weight, so that the load on the load-bearing walls of the building does not increase. This property is especially important when insulating old buildings. The main disadvantage is that it easily absorbs moisture, therefore, vapor barrier films should be used during installation.

- Glass wool. It is possible to work with the material only in protective clothing, goggles and a respirator. As the temperature rises, it becomes a single glass mass. Has a budget price tag, but fits in 2-3 layers.

- Styrofoam. According to some reports, it is not safe for health, therefore, it is not recommended for use in living rooms.Small rodents "love" it very much, which eventually causes a persistent specific smell. Available on the market in various thicknesses and densities.

Foamed polyethylene film coated with aluminum foil is ideal as a vapor barrier gasket that prevents condensation from forming inside the partition. For information on how to insulate walls with drywall, see this video:

The use of the film will save 95% of heat. At the same time, sound insulation in the room will significantly improve.

Working with mineral wool

Mineral wool It is not a self-sufficient coating, its surface is not pleasant to the touch, and the ingress of fibers into the respiratory system causes irritation, therefore the material requires additional finishing. But the unpleasant aspects can be avoided if you follow safety and operating procedures. A variety of protective equipment should be used when handling this material.

Mandatory remedies include

- Construction spraying device,

- Gloves, better latex,

- Protective glasses,

- Long sleeved clothes.

Do not work with this material near open food or drinking water. After installing it and applying a decorative and protective layer of mineral wool, it becomes absolutely safe for the environment.

Mineral wool is easy to install, does not change its technical parameters during operation, is fireproof and has unique thermal insulation qualities. Thanks to these advantages, the material has won a solid position in the construction market.

© Gipsokart.ru.

Advantages and disadvantages

When installing the gypsum board on the frame, the area of the room will slightly decrease

The main advantage of using drywall sheets as insulation is the high efficiency of the material.

At the same time, the surface of the sheets does not require additional leveling and is ready for laying the finishing decorative layer of the design.

- installation by means of the frame “eats up” the area of the room;

- the material is very fragile, not suitable for hanging heavy objects;

- GKL does not differ in mechanical strength, it breaks easily upon impact;

- untreated sheets give off dust that is harmful to health.

How to putty drywall for painting

Which is better: gypsum plasterboard and drywall on the walls

Correct wall insulation in a foam concrete house

Wall insulation with foam or mineral wool

Insulation of external walls with sawdust

How to properly insulate aerated concrete walls from the outside

Video “Drywall. Installation sequence "

Video about wall insulation with plasterboard. The video explains all the main stages of this work.

We recommend that you familiarize yourself

Insulation of walls from the inside with foam - all pros and cons

Insulation of walls from the inside with mineral wool - technology and useful tips

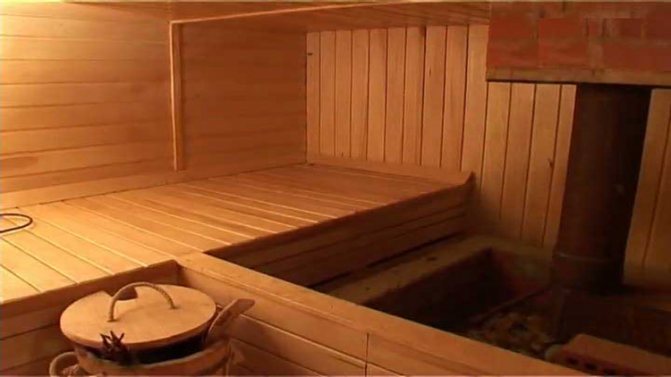

Correct insulation of the walls of the bath from the inside with your own hands

Warming of drywall partitions. Material selection

Today, the choice of heaters for drywall structures is simply huge. In this article, we will consider the most common of them.

The following materials are distinguished:

- mineral wool;

- coco cork wood and combination board;

- expanded polystyrene;

- Styrofoam;

- rockwool.

- reflector.

To achieve maximum sound insulation in gypsum partitions, builders most often use mineral wool. It is important to remember that this soundproofing material comes in different shapes, sizes and thicknesses.

The most common type of mineral wool can be called roll "mats". They have the following widths: 40, 60 and 120 cm. This is exactly the width of the horizontal step of the plasterboard frame. Rolled "mats" are of the following thickness: 50, 75, 100 mm. This is the thickness of the metal profile for the installation of plasterboard walls.

It is important to remember that when laying mineral wool in the profile of a drywall structure, at least a minimum air space must remain.

In addition, mineral wool can be in the form of slabs.Dimensions: 60x100 cm. The thickness is the same as that of roll-up mats.

How to properly install mineral wool

Before laying the mineral wool, you need to have a respirator, construction gloves, and a hat.

When the frame is fully assembled, the mineral wool is cut into strips of certain sizes using a drywall knife. The cut strips are laid tightly along the frame racks. If you are joining the ends, it is better to lay an overlap of 10 to 15 cm.

Coco-cork wood and combination board

If it is important to achieve maximum soundproofing of the plasterboard partition, balsa and coir slabs can be used. You can combine these soundproofing materials. Then the maximum permissible soundproofing effect can be achieved.

Expanded polystyrene plates are perhaps one of the best thermal insulation materials used in the insulation of gypsum plasterboard partitions. Expanded polystyrene boards have different sizes, as well as density. Usually it is 120x60 and 100x50 cm with a thickness of 2 to 5 cm. In terms of density, they differ into soft, semi-rigid and hard. They are connected using grooves.

They also speak well of polystyrene as an insulation material. High heat transfer, a wide range of sizes and shapes, allows you to insulate any wall made of plasterboard construction.

If it is decided to carry out insulation exclusively with the help of mineral wool, then Rockwool will be an indispensable insulation. After all, it is no worse than the same foam. As an advantage, it is worth emphasizing the fact that Rockwool can have a heat reflector. It should be remembered that ROCKWOOL mineral wool comes in both slabs and rolls. If it is a roll, then it can have a thickness of 30, 40, 50 cm; length 5, 8, 10 m, standard width 1 m. If it is a plate, then dimensions: 100x60 cm with a thickness of 5 to 20 cm. This insulation is able to withstand a large temperature difference, has good water-repellent and fire-resistant characteristics.

Polymer heat reflectors are used to keep the temperature in a particular room. They are usually sold in rolls with dimensions: 2-5 mm thick. width - 1 m. long - 30 m. The thickness of the heat-reflector foil itself can also be different.

Decorative partitions

With the help of plasterboard partitions, an unusual interior is often created. If you wish, you can make them in different shapes, make niches and openings. Installation of such structures will cost you a little more. Our specialists are real professionals with solid experience. We can easily implement any ideas. The design of the room will become what you want.

We will first draw up a plan or make a layout. Then the details are agreed with the clients. You can use the services of our professional designer, who will certainly take into account the nuances of a particular interior. In the end, you will get an excellent result. A decorative plasterboard partition is the best solution for those who want to create an unusual interior at no special cost.

Insulation of drywall partitions with mineral wool

It is not difficult to carry out competent insulation and sound insulation of drywall partitions. By itself, drywall has good soundproofing characteristics. It is possible to increase the heat and sound insulation in the room thanks to the stitching in two layers.

Mineral wool is considered one of the most used insulation materials. Important: before installing the metal frame on the profile guides, self-adhesive insulating tape must be glued to the floor, ceiling and walls.

The self-adhesive tape is made of polystyrene components and has a thickness of 3-4 mm. It is glued to effectively absorb sound from the ceiling, walls, floor, and even from the frame itself from the profiles.

The insulating tape is also glued to the U-shaped brackets.It (insulating tape - ed.) Is nailed to the wall, after which the rack profiles are aligned and screwed to the brackets. Then the distance from the indent from the wall to the metal frame is measured. Rolled mineral wool is cut into strips 10-15 cm larger than the size we need. It is recommended to overlap the mineral wool from above by 10-15 cm, as this will allow the insulation to be fixed more rigidly between the frame and the wall.

Having secured the first layer, you can proceed with the installation of the second. It is worth remembering that the second layer should be overlapped (10-15 cm). Remember, the denser the mineral wool is, the better the sound insulation will be. However, do not forget about the minimum gap (2-3 mm).

After the mineral wool lies well in the metal frame, everything is sewn up from both sides with plasterboard sheets.

What insulation is better for drywall

To create comfortable living conditions, it is important to choose the right not heating system, but insulation for the walls. This allows you not only to keep warm, but also to save on utility bills. It should be noted that the use of drywall for this process is best suited. It allows you to create a pleasant microclimate, while perfectly leveling the walls, creates an almost finished surface for finishing. Consider the thermal insulation qualities of drywall, which filler to choose for it in order to create warmth and comfort in the house.

Thermal insulation properties of gypsum board

The use of gypsum plasterboards allows you to create high thermal and sound insulation not only due to the pores that form inside it, but the air gap behind the slab. Therefore, for a relatively warm climate, you can not use additional insulation. As for the gypsum board itself, the level of thermal insulation is determined by the coefficient of thermal conductivity. For example, drywall has a thermal conductivity coefficient of only 0.15, which is significantly lower than reinforced concrete. This allows not only to create warmth in the winter, but also in the summer there will be coolness.

It is worth noting that the method of installing drywall affects the level of thermal insulation. To achieve a greater effect, it is recommended to use a frame version rather than glue. The resulting layer under the frame creates additional wall insulation. But, one way or another, insulation will be needed to create a warm atmosphere.

Wall insulation from the inside

The first thing to decide with is where the insulation will take place. For private houses, it is better to choose outside insulation, this is a more effective option. If the process is carried out in an apartment, then you will have to carry out internal insulation. For it, the following materials are used for drywall:

- Styrofoam. It is suitable for plasterboard construction, but its use is rare. There are several important drawbacks that will cause the rejection of foam: exposed to rodents, they can create a hole and create "tunnels" for living, it is also not fully proven how harmful foam is for home improvement;

- Polystyrene. Has the same disadvantages as the previous version;

- Glass wool. Also used as insulation for plasterboard walls. Main advantages: low price, good protection from cold. But there is also such a drawback as the complexity of the work. The process itself is easy, but glass fibers during processing, getting on the human skin, cause irritation, inflame the mucous membrane;

- Izolon. This insulation has no particular drawbacks. It has a low price, a low level of thermal conductivity, and it is easy to work with. This is ideal for insulating small buildings, since isolon is a thin material that does not take up space;

- Basalt wool. In terms of its main qualities, it resembles glass wool, only work with it takes place without harm to human health.Due to the fact that it is made from rocks of magmatic origin, it has a high level of fire resistance. More expensive than glass wool.

So, in order to choose the right insulation for drywall, you need to decide what is the price for insulation, where exactly the building will be insulated (inside or outside). Isolon and basalt wool are best suited for internal insulation. The latter option is more common, it is easier to purchase it at different prices, while it is completely safe during operation.

Varieties of material

Today on the market you can find a huge number of insulation products that differ in their quality characteristics.

Heaters include the following materials:

- Styrofoam;

- expanded polystyrene;

- mineral wool;

- reflector (isolon);

- coconut and cork plates.

Each of them has a specific structure and parameters.

To choose the right insulation, you must initially know the characteristics of each of them.

Features of foam and polystyrene foam in insulation

These funds have been used in finishing work for a long time. They have earned recognition for their optimal cost and excellent quality characteristics.

- Low weight, which avoids additional loads on the metal-profile frame.

- Moisture resistance - products do not absorb moisture, and under its influence they are not able to deform.

- High thermal resistance - heated air masses will not be able to pass through their structure.

- Safety - materials can be used without additional hand protection.

- Durability - the service life of polystyrene and polystyrene is the same and is more than 25 years.

- Practicality - the products are easy to cut and also easy to assemble.

Styrofoam or polystyrene helps to make the process of building insulation faster and of better quality. Despite the large number of advantages, the materials also have disadvantages. These include the following characteristics:

- Low strength during physical exertion.

- Immunity to fire - Styrofoam does not burn, but can melt.

- Toxicity - the manufacturing process of materials involves the use of synthetic raw materials.

In addition, polystyrene and expanded polystyrene act as vapor barriers. This negatively affects the insulation of rooms with high air humidity and high temperature conditions.

Mineral wool and its characteristics

There are several types of this material. These include the following products:

- glass wool;

- basalt wool;

- stone wool;

- slag wool.

Each of them has certain advantages and disadvantages.

The most popular insulation is glass wool. It is made from natural raw materials - sand, borax, soda and limestone.

The advantages include the following characteristics:

- Non-toxic - the material does not emit harmful substances.

- Good thermal conductivity.

- Resistant to aggressive environments.

- Fire resistance.