Device and principle of operation

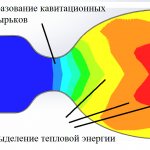

The principle of operation of a cavitation heat generator consists in the heating effect due to the conversion of mechanical energy into heat. Now let's take a closer look at the cavitation phenomenon itself. When excessive pressure is created in the liquid, vortices arise, due to the fact that the pressure of the liquid is greater than that of the gas contained in it, the gas molecules are released into separate inclusions - the collapse of bubbles. Due to the pressure difference, the water tends to compress the gas bubble, which accumulates a large amount of energy on its surface, and the temperature inside reaches about 1000 - 1200 ° C.

When the cavitation cavities pass into the zone of normal pressure, the bubbles are destroyed, and the energy from their destruction is released into the surrounding space. Due to this, thermal energy is released, and the liquid is heated from the vortex flow. The operation of heat generators is based on this principle, then consider the principle of operation of the simplest version of a cavitation heater.

The simplest model

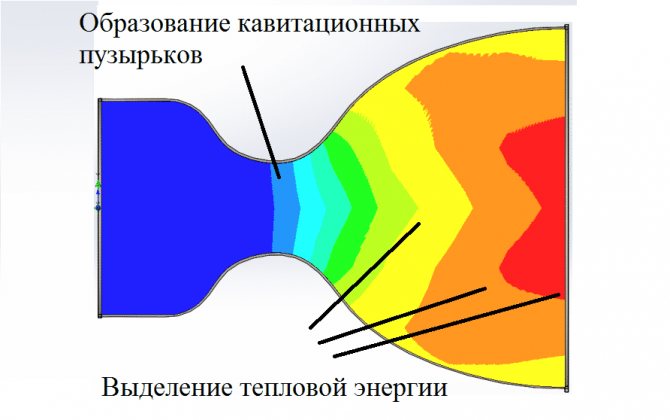

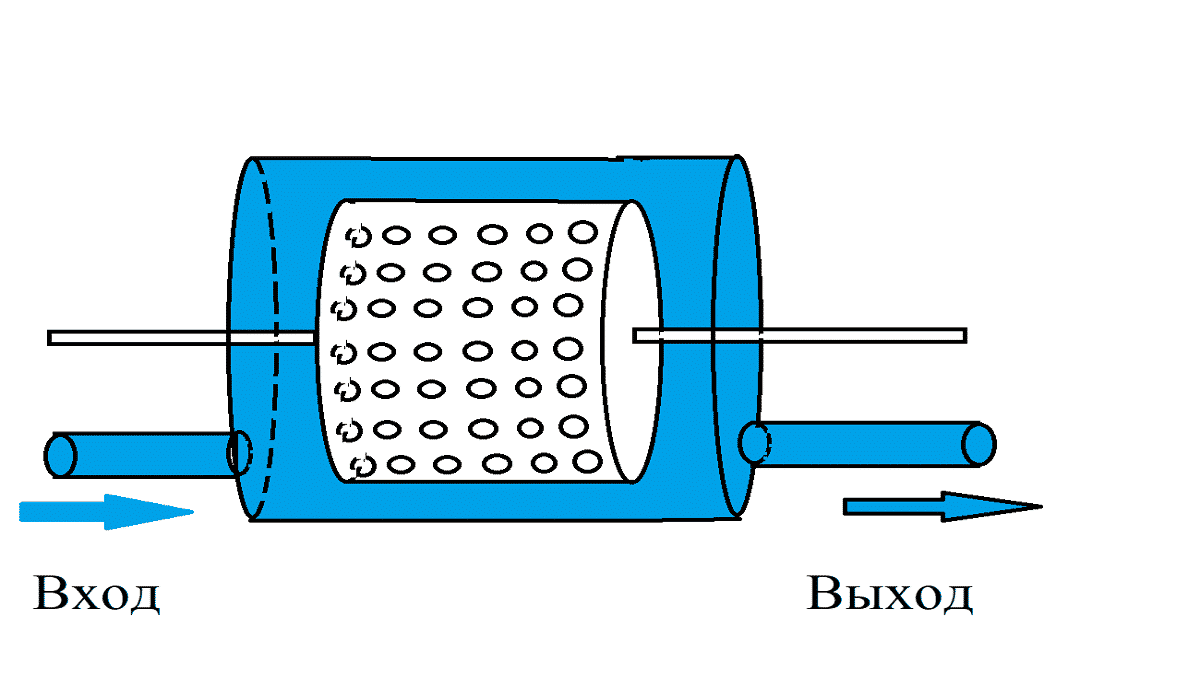

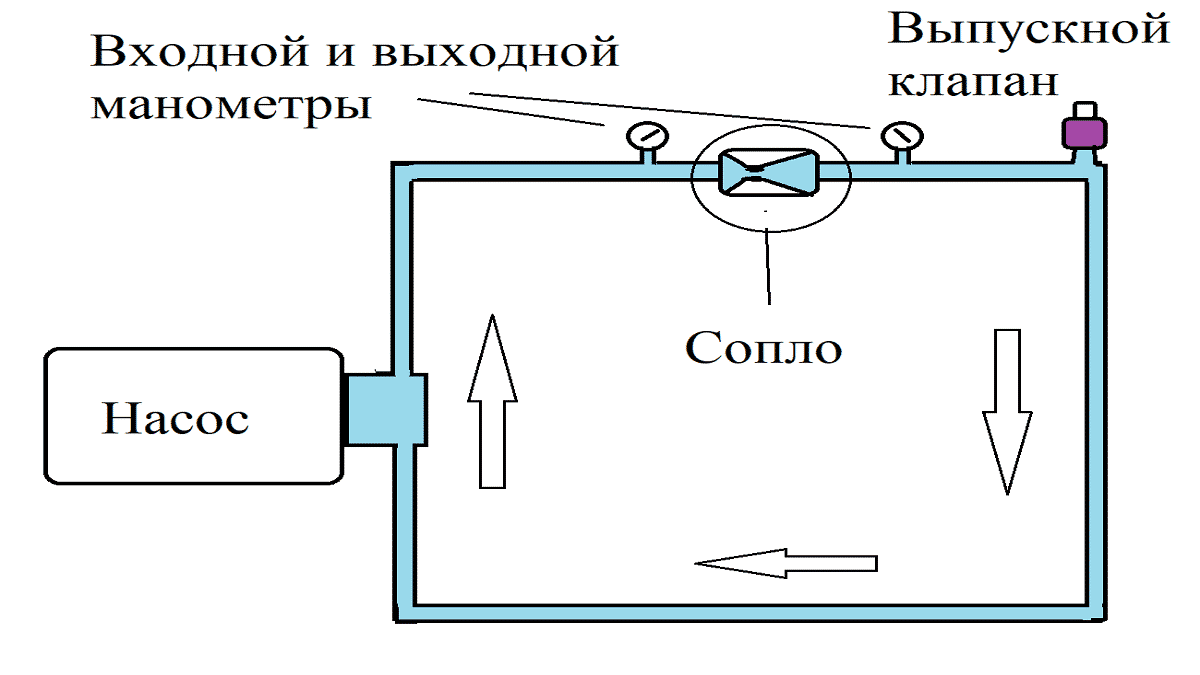

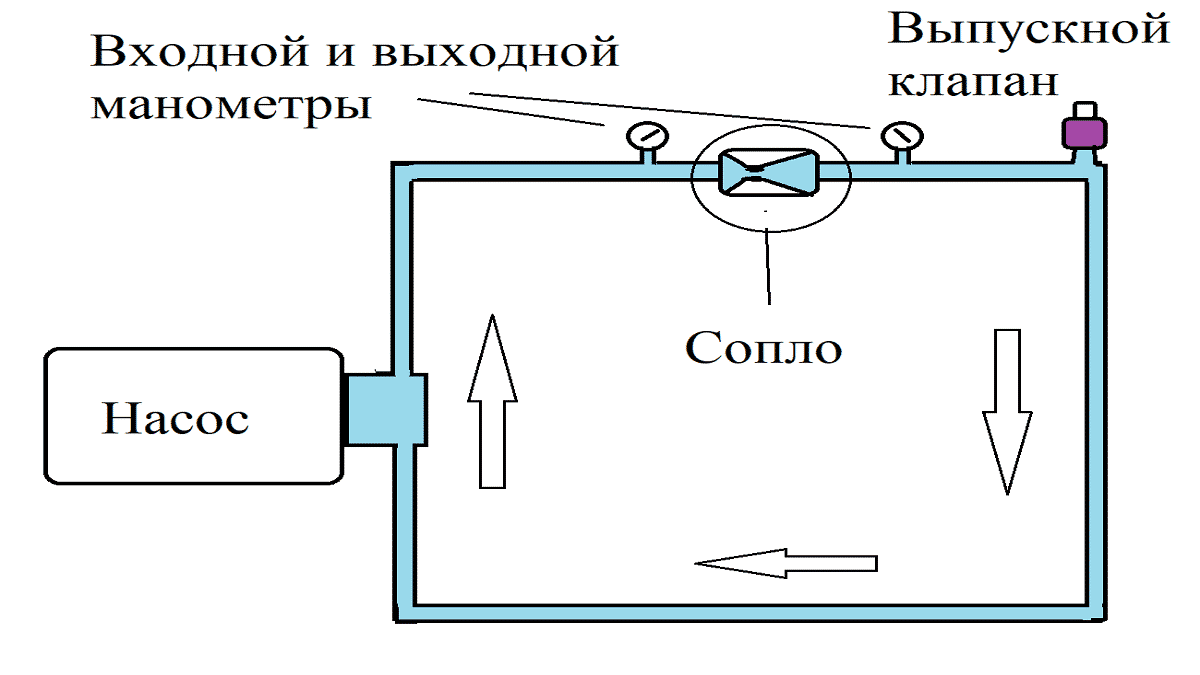

Fig. 1: Functional principle of the cavitation heat generator

Look at Figure 1, here the device of the simplest cavitation heat generator is presented, which consists in pumping water by a pump to the point of the pipeline narrowing. When the water flow reaches the nozzle, the pressure of the liquid increases significantly and the formation of cavitation bubbles begins. When leaving the nozzle, the bubbles release thermal power, and the pressure after passing through the nozzle is significantly reduced. In practice, multiple nozzles or tubes can be installed to increase efficiency.

Potapov's ideal heat generator

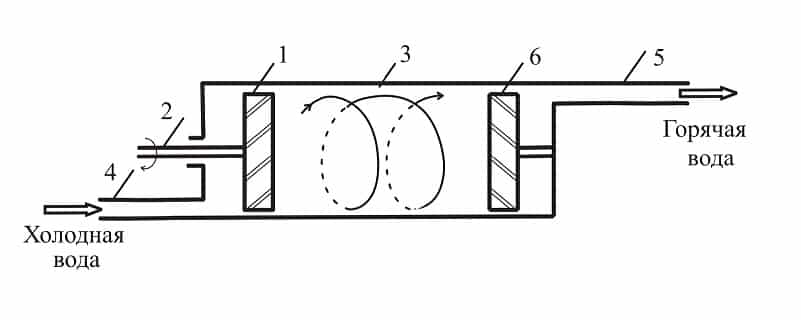

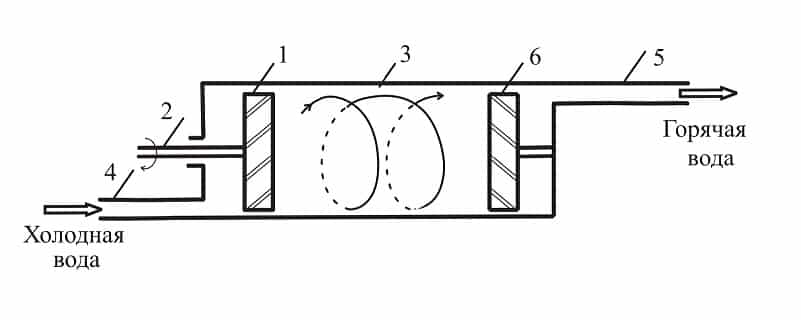

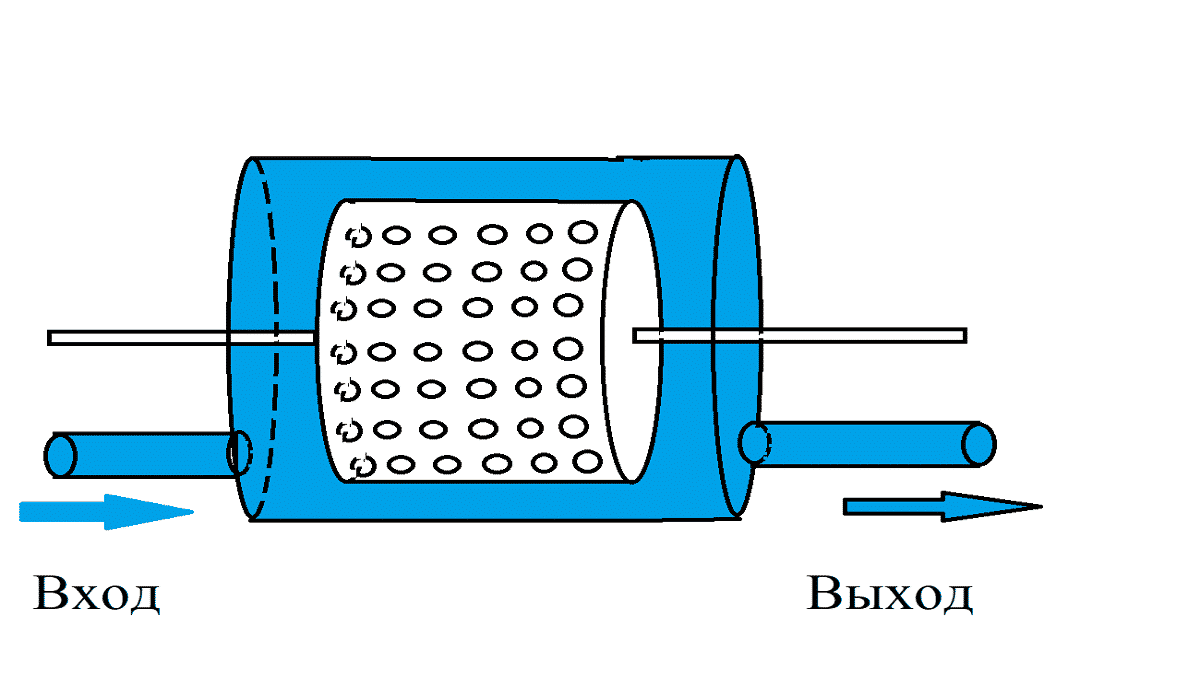

The Potapov heat generator, which has a rotating disk (1) installed opposite the stationary one (6), is considered an ideal installation option. Cold water is supplied from the pipe located at the bottom (4) of the cavitation chamber (3), and the outlet is already heated from the upper point (5) of the same chamber. An example of such a device is shown in Figure 2 below:

Fig. 2: Potapov's cavitation heat generator

But the device did not receive wide distribution due to the lack of a practical justification for its operation.

What lies at the heart of the work

Cavitation denotes the formation process vaporous bubbles in the water columnThis is facilitated by a slow decrease in water pressure at high flow rates. The formation of cavities or cavities filled with vapor can also be caused by the passage of an acoustic wave or the emission of a laser pulse. Closed areas of air, or cavitation voids, are moved by water to a high-pressure area, where they collapse with the emission of a shock wave. The phenomenon of cavitation cannot occur in the absence of the specified conditions.

The physical process of the cavitation phenomenon is akin to the boiling of a liquid, but during boiling, the pressure of water and vapor in the bubbles is average in value and the same. During cavitation, the pressure in the liquid is above average and above the vapor pressure. Lowering the same pressure is local in nature.

When the necessary conditions are created, gas molecules, which are always present in the water column, begin to escape into the formed bubbles. This phenomenon is intense, since the temperature of the gas inside the cavity reaches up to 1200 ° C due to the constant expansion and contraction of the bubbles.Gas in cavitation cavities contains a greater number of oxygen molecules and, when interacting with inert materials of the body and other parts of the heat generator, leads to their rapid corrosion and destruction.

Studies show that even materials inert to this gas - gold and silver - are subject to the destructive action of aggressive oxygen. In addition, the phenomenon of the collapse of the air pockets causes a sufficient amount of noise, which is an undesirable problem.

Many enthusiasts have made the cavitation process useful for creating heating heat generators for a private house. The essence of the system is enclosed in a closed casing in which a water jet moves through a cavitation device; an ordinary pump is used to obtain pressure. In Russia, for the first invention of the heating installation, granted a patent in 2013... Bubble rupture is formed under the action of an alternating electric field. In this case, the vapor cavities are small in size and do not interact with the electrodes. They move into the thickness of the liquid, and there is an opening with the release of additional energy in the body of the water flow.

Views

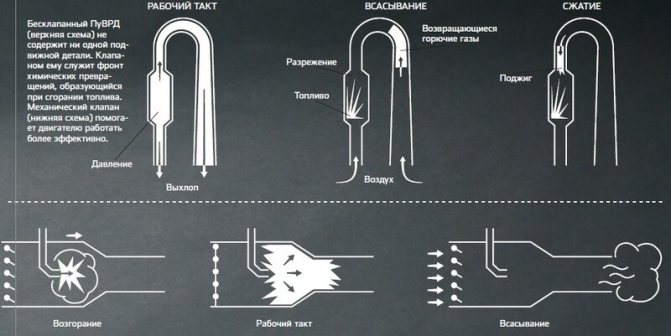

The main task of a cavitation heat generator is the formation of gas inclusions, and the quality of heating will depend on their quantity and intensity. In modern industry, there are several types of such heat generators, which differ in the principle of generating bubbles in a liquid. The most common are three types:

- Rotary heat generators - the working element rotates due to the electric drive and generates fluid swirls;

- Tubular - change the pressure due to the system of pipes through which the water moves;

- Ultrasonic - the inhomogeneity of the liquid in such heat generators is created due to sound vibrations of low frequency.

In addition to the above types, there is laser cavitation, but this method has not yet found industrial implementation. Now let's consider each of the types in more detail.

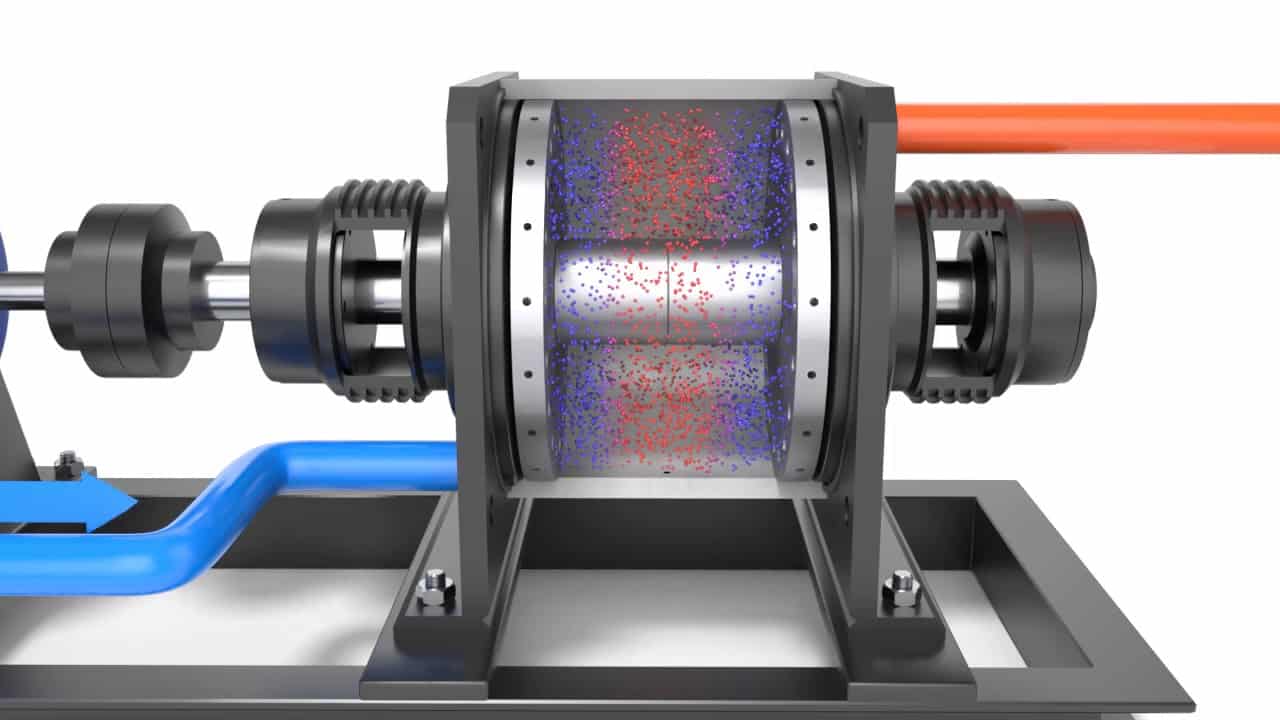

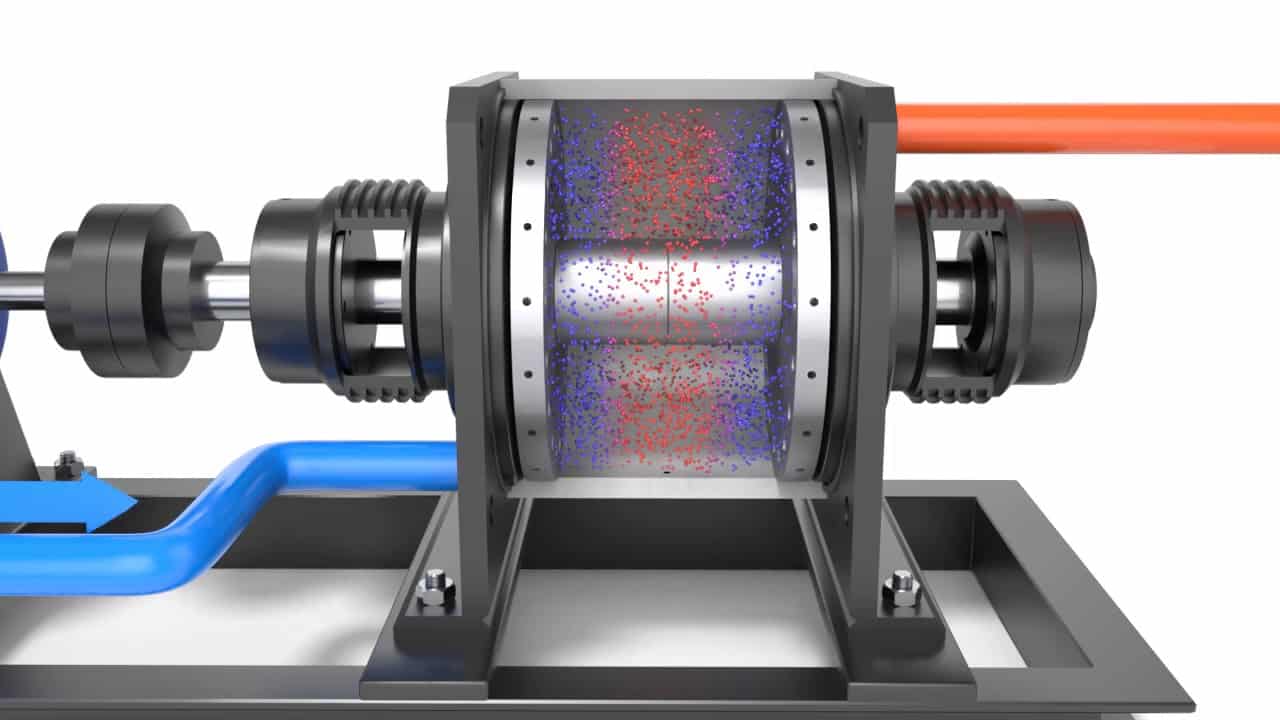

Rotary heat generator

It consists of an electric motor, the shaft of which is connected to a rotary mechanism designed to create turbulence in the liquid. A feature of the rotor design is a sealed stator, in which heating takes place. The stator itself has a cylindrical cavity inside - a vortex chamber in which the rotor rotates. The rotor of a cavitation heat generator is a cylinder with a set of grooves on the surface; when the cylinder rotates inside the stator, these grooves create inhomogeneity in the water and cause cavitation processes.

Fig. 3: design of the rotary type generator

The number of depressions and their geometric parameters are determined depending on the model of the vortex heat generator. For optimal heating parameters, the distance between the rotor and the stator is about 1.5 mm. This design is not the only one of its kind; for a long history of modernizations and improvements, the working element of the rotary type has undergone a lot of transformations.

One of the first effective models of cavitation transducers was the Griggs generator, which used a disc rotor with blind holes on the surface. One of the modern analogues of disk cavitation heat generators is shown in Figure 4 below:

Fig. 4: disc heat generator

Despite the simplicity of the design, rotary-type units are quite difficult to use, since they require accurate calibration, reliable seals and compliance with geometric parameters during operation, which makes them difficult to operate. Such cavitation heat generators are characterized by a rather low service life - 2 - 4 years due to cavitation erosion of the body and parts. In addition, they create a fairly large noise load during the operation of the rotating element.The advantages of this model include high productivity - 25% higher than that of classic heaters.

Tubular

The static heat generator has no rotating elements. The heating process in them occurs due to the movement of water through pipes tapering along the length or due to the installation of Laval nozzles. The supply of water to the working body is carried out by a hydrodynamic pump, which creates a mechanical force of the liquid in a narrowing space, and when it passes into a wider cavity, cavitation vortices arise.

Unlike the previous model, tubular heating equipment does not make much noise and does not wear out so quickly. During installation and operation, you do not need to worry about accurate balancing, and if the heating elements are destroyed, their replacement and repair will be much cheaper than with rotary models. The disadvantages of tubular heat generators include significantly lower performance and bulky dimensions.

Ultrasonic

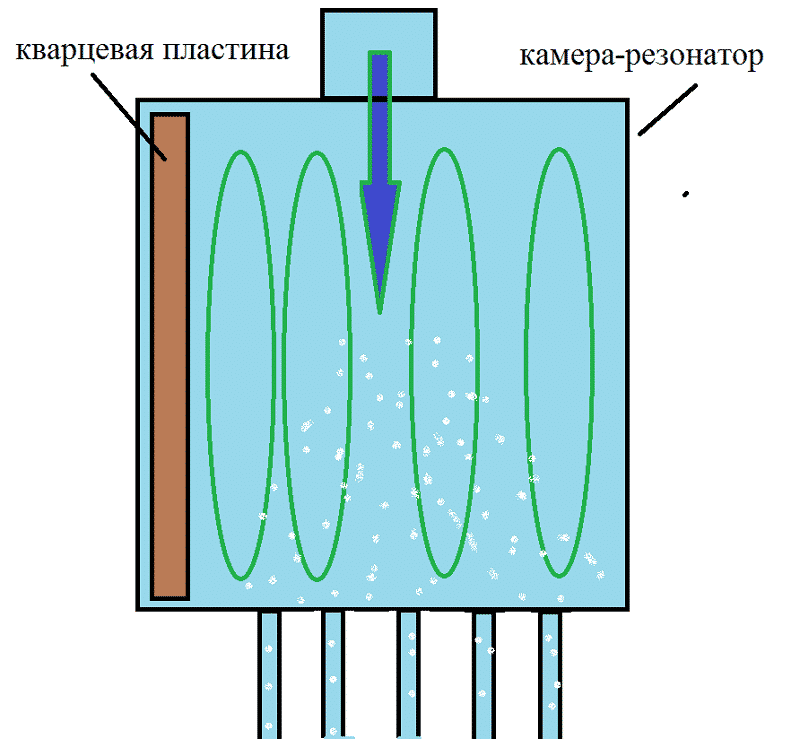

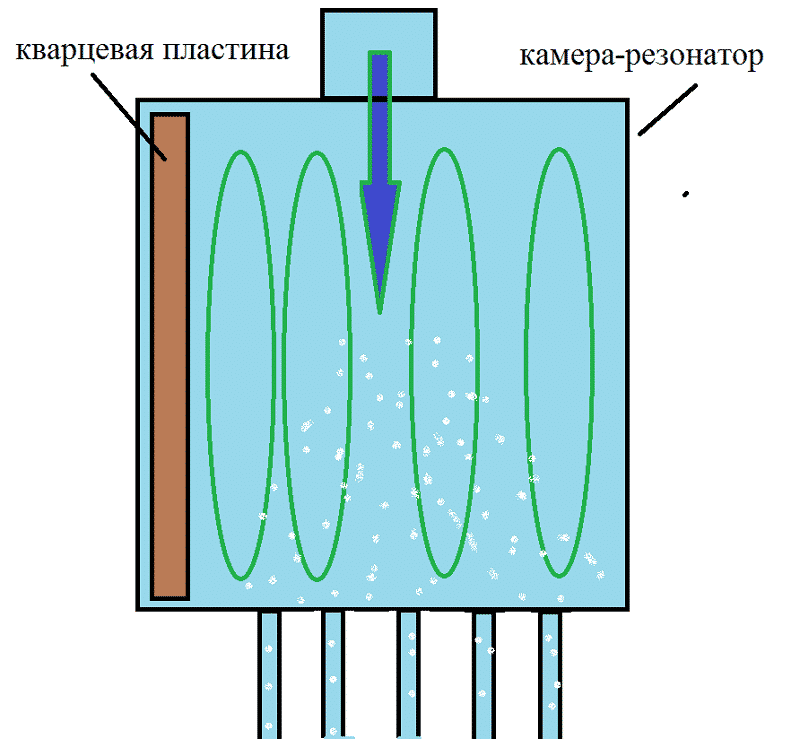

This type of device has a resonator chamber tuned to a specific frequency of sound vibrations. A quartz plate is installed at its input, which vibrates when electrical signals are applied. The vibration of the plate creates a ripple effect inside the liquid, which reaches the walls of the resonator chamber and is reflected. During the return motion, the waves meet with forward vibrations and create hydrodynamic cavitation.

Fig. 5: working principle of the ultrasonic heat generator

Further, the bubbles are carried away by the water flow along the narrow inlet pipes of the thermal installation. When passing into a wide area, the bubbles collapse, releasing thermal energy. Ultrasonic cavitation generators also have good performance as they do not have rotating elements.

Generator insulation

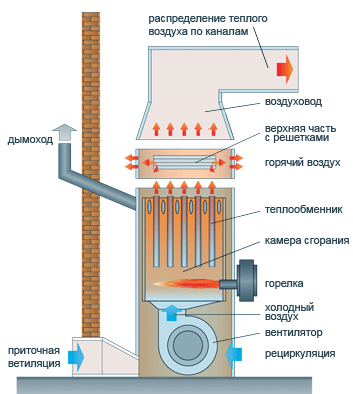

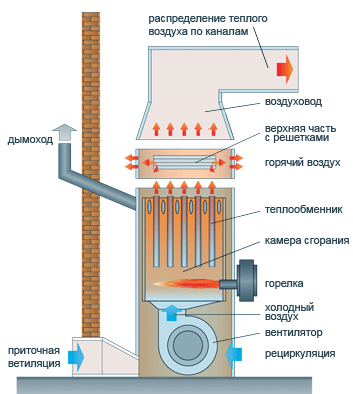

Connection diagram of the heat generator to the heating system.

First you need to make a casing of insulation. Take a sheet of galvanized sheet or thin aluminum for this. Cut two rectangles out of it if you will be making a casing of two halves. Or one rectangle, but with the expectation that after manufacturing, Potapov's vortex heat generator, which was assembled by hand, will completely fit in it.

It is best to bend the sheet on a large diameter pipe or use a cross member. Place the cut sheet on it and press the wooden block on top with your hand. With the other hand, press on the sheet of tin so that a small bend is formed along the entire length. Move the workpiece slightly and repeat the operation again. Do this until you have a cylinder.

- Connect it with the lock used by the downpipe tinsmiths.

- Make covers for the casing with holes for connecting the generator.

- Wrap insulating material around the device. Fix the insulation with wire or thin strips of sheet metal.

- Place the device in the casing, close the covers.

There is another way to increase heat production: for this you need to figure out how the Potapov vortex generator works, the efficiency of which can approach 100% and higher (there is no consensus why this happens).

During the passage of water through the nozzle or jet, a powerful stream is created at the outlet, which hits the opposite end of the device. It twists, and heating occurs due to the friction of the molecules. This means that by placing an additional obstacle inside this stream, it is possible to increase the mixing of the liquid in the device.

Once you know how it works, you can start designing additional enhancements. It will be a vortex damper made of longitudinal plates located inside two rings in the form of an aircraft bomb stabilizer.

Stationary heat generator diagram.

Tools: welding machine, angle grinder.

Materials: sheet metal or flat iron, thick-walled pipe.

Make two rings 4-5 cm wide from a pipe with a smaller diameter than the Potapov vortex heat generator. Cut identical strips from strip metal. Their length should be equal to a quarter of the length of the body of the heat generator itself. Choose the width so that after assembly there is a free hole inside.

- Secure the plate in a vise. Hang it on one side and the other of the ring. Weld the plate to them.

- Remove the workpiece from the clamp and flip it 180 degrees. Place the plate inside the rings and secure in the clamp so that the plates are opposite each other. Fix 6 plates in this way at an equal distance.

- Assemble the vortex heat generator by inserting the described device opposite the nozzle.

Probably, this product can be further improved. For example, instead of parallel plates, use steel wire by winding it into an air ball. Or make holes of different diameters on the plates. Nothing is said about this improvement, but this does not mean that it should not be done.

Diagram of the device of the heat gun.

- Be sure to protect Potapov's vortex heat generator by painting all surfaces.

- Its internal parts during operation will be in a very aggressive environment caused by cavitation processes. Therefore, try to make the body and everything in it from thick material. Don't skimp on hardware.

- Make several different caps with different inlets. Then it will be easier to select their diameter in order to obtain high performance.

- The same applies to the vibration damper. It can also be modified.

Build a small laboratory bench where you will run in all the characteristics. To do this, do not connect consumers, but loop the pipeline to the generator. This will simplify its testing and selection of the required parameters. Since it is hardly possible to find sophisticated devices for determining the coefficient of efficiency at home, the following test is proposed.

Turn on the vortex heat generator and note the time when it warms up the water to a certain temperature. It is better to have an electronic thermometer, it is more accurate. Then modify the design and run the experiment again, observing the rise in temperature. The more the water heats up at the same time, the more preference will have to be given to the final version of the established improvement in the design.

Have you noticed that the price of heating and hot water supply has increased and do not know what to do about it? The solution to the problem of expensive energy resources is a vortex heat generator. I will talk about how a vortex heat generator is arranged and what is the principle of its operation. You will also find out if it is possible to assemble such a device with your own hands and how to do it in a home workshop.

Application

In industry and in everyday life, cavitation heat generators have found implementation in a wide variety of areas of activity. Depending on the tasks set, they are used for:

- Heating - inside the installations, mechanical energy is converted into thermal energy, due to which the heated liquid moves through the heating system. It should be noted that cavitation heat generators can heat not only industrial facilities, but also entire villages.

- Heating running water - the cavitation unit is capable of quickly heating a liquid, due to which it can easily replace a gas or electric column.

- Mixing liquid substances - due to the rarefaction in the layers with the formation of small cavities, such aggregates allow achieving the proper quality of mixing of liquids that do not naturally combine due to different densities.

Buy or craft?

As you can see, the prices for heat generators are cosmic. Not everyone can afford such an alternative power source, so economists are trying to make it with their own hands. Buying or making on your own directly depends not only on the well-being of the family, but also on the skills and abilities of the person. If there are none, it is better not to risk and not waste time, because the design of the device has a rather complex structure.

Thus, the cavitation heat generator is an excellent alternative source of heating for the home. However, its high cost makes it inaccessible to the majority of the world's population.

You can assemble it with your own hands, but this step is justified only if you have a special skill.

Pros and cons

In comparison with other heat generators, cavitation units have a number of advantages and disadvantages.

The advantages of such devices include:

- Much more efficient mechanism for obtaining thermal energy;

- Consumes significantly less resources than fuel generators;

- It can be used for heating both low-power and large consumers;

- Completely environmentally friendly - does not emit harmful substances into the environment during operation.

The disadvantages of cavitation heat generators include:

- Relatively large dimensions - electric and fuel models are much smaller, which is important when installed in an already operated room;

- High noise due to the operation of the water pump and the cavitation element itself, which makes it difficult to install it in household premises;

- Ineffective ratio of power and performance for rooms with a small square area (up to 60m2 it is more profitable to use a unit running on gas, liquid fuel or equivalent electric power with a heating element). \

Advantages and disadvantages

Like any other device, a cavitation-type heat generator has its positive and negative sides.

Among the advantages the following indicators can be distinguished:

- availability;

- huge savings;

- does not overheat;

- Efficiency tending to 100% (it is extremely difficult for other types of generators to achieve such indicators);

- availability of equipment, which makes it possible to assemble the device no worse than the factory one.

The weaknesses of the Potapov generator are considered:

- volumetric dimensions that occupy a large area of the living area;

- high level of engine noise, which makes it extremely difficult to sleep and rest.

The generator used in industry differs from the home version only in size. However, sometimes the power of a home unit is so high that it makes no sense to install it in a one-room apartment, otherwise the minimum temperature during operation of the cavitator will be at least 35 ° C.

The video shows an interesting version of a vortex heat generator for solid fuel

[su_youtube url = "https://www.youtube.com/embed/0tKOVk6eWuQ?feature=oembed"]

DIY CTG

The simplest option for implementation at home is a tubular-type cavitation generator with one or more nozzles for heating water. Therefore, we will analyze an example of making just such a device, for this you will need:

- Pump - for heating, be sure to choose a heat pump that is not afraid of constant exposure to high temperatures. It must provide a working pressure at the outlet of 4 - 12 atm.

- 2 pressure gauges and sleeves for their installation - located on both sides of the nozzle to measure the pressure at the inlet and outlet of the cavitation element.

- Thermometer for measuring the amount of heating of the coolant in the system.

- Valve for removing excess air from the cavitation heat generator.Installed at the highest point of the system.

- Nozzle - must have a bore diameter from 9 to 16 mm, it is not recommended to do less, since cavitation can occur already in the pump, which will significantly reduce its service life. The shape of the nozzle can be cylindrical, conical or oval, from a practical point of view, any will suit you.

- Pipes and connecting elements (heating radiators in their absence) are selected in accordance with the task at hand, but the simplest option is plastic pipes for soldering.

- Automation of turning on / off the cavitation heat generator - as a rule, it is tied to the temperature regime, set to turn off at about 80 ° C and to turn on when it drops below 60 ° C. But you can choose the operating mode of the cavitation heat generator yourself.

Fig. 6: diagram of a cavitation heat generator

Before connecting all the elements, it is advisable to draw a diagram of their location on paper, walls or on the floor. Locations must be located away from flammable elements or the latter must be removed at a safe distance from the heating system.

Collect all the elements as you depicted in the diagram, and check the tightness without turning on the generator. Then test the cavitation heat generator in the operating mode, a normal rise in the temperature of the liquid is 3 - 5 ° C in one minute.

Operating principle

The generator works on the principle of cavitation, when water is poured into a special turbine compartment (cavitator), and the pump starts to spin the cavitator. In this case, the formed water bubbles begin to collapse, generating additional heat, which heats the coolant.

In theory, Potapov defended a number of scientific works, where he described the process of generating renewable energy. In practice, it is difficult to prove this, however, a cavitation heat generator takes place among other alternative methods of generating heat.

Heater types

The cavitation heating boiler belongs to one of the common types of heaters. The most demanded ones:

- Rotary installations, among which the Griggs device deserves special attention. The essence of its action is based on a rotary centrifugal pump. The design described outwardly resembles a disc with several holes. Each such niche is called a Griggs cell, their number and functional parameters are interdependent with the speed of the drive, the type of generator set used. The working fluid is heated in the space between the rotor and stator due to its rapid movement along the disc surface.

- Static heaters. The boilers are devoid of any moving parts; cavitation in them is ensured by special Laval elements. A pump installed in the heating system sets the required water pressure, which begins to move quickly and heat up. Due to the narrow holes in the nozzles, the liquid moves at an accelerated rate. Due to its rapid expansion, the cavitation necessary for heating is achieved.

The choice of this or that heater depends on the needs of the person. It should be borne in mind that the rotary cavitator is more efficient, moreover, it is smaller in size.

The peculiarity of the static unit is the absence of rotating parts, which is what determines its long operational life. Duration of operation without maintenance is up to 5 years. If the nozzle breaks, it can be easily replaced, which is much cheaper compared to purchasing a new working element for a rotary installation.

Manufacturing and development of a cavitator

Stationary heat generator device diagram.

There are many designs of static cavitators, but in almost all cases they are made in the form of a nozzle. The nozzle is most often taken as a basis and modified by the designer. The classic design is shown in the figure (IMAGE 1).

The first thing you need to pay attention to is the section of the channel between the confuser and the diffuser. Its cross-section should not be greatly narrowed, thereby trying to ensure the maximum pressure drop. The amount of water that is pumped through the nozzle will be too small. When mixed with cold water, it will transfer insufficient heat to it. This means that the total volume of water will not be able to heat up quickly. In addition, the small cross-section of the channel will contribute to the airing of water that enters the inlet pipe of the working pump. As a result, this pump will operate noisily, and cavitation may occur in the device itself.

The best performance can be achieved with a duct diameter of 10-15 mm.

Harmful consequences

Cavitation damage (pump part)

Propeller cavitation damage

The chemical aggressiveness of gases in bubbles, which also have a high temperature, causes erosion of materials with which the liquid comes into contact, in which cavitation develops. This erosion is one of the factors of the harmful effects of cavitation. The second factor is due to large overshoots of pressure arising from the collapse of bubbles and affecting the surfaces of these materials.

Cavitation erosion of metals causes destruction of ship propellers, working bodies of pumps, hydraulic turbines, etc., cavitation is also the cause of noise, vibration and a decrease in the efficiency of hydraulic units.

The collapse of cavitation bubbles leads to the fact that the energy of the surrounding liquid is concentrated in very small volumes. Thus, hot spots are formed and shock waves are generated, which are sources of noise and lead to erosion of the metal. Cavitation noise is a particular problem on submarines, as it reduces stealth. Experiments have shown that even substances chemically inert to oxygen (gold, glass, etc.) are exposed to the harmful, destructive effects of cavitation, albeit much slower. This proves that in addition to the factor of chemical aggressiveness of gases in bubbles, the factor of pressure overshoots arising from the collapse of bubbles is also important. Cavitation leads to high wear on the working parts and can significantly shorten the life of the screw and pump. In metrology, when using ultrasonic flow meters, cavitation bubbles modulate waves in a wide spectrum, including at frequencies emitted by the flow meter, which leads to distortion of its readings.

Design features

Despite the simplicity of the device, there are features that must be taken into account when assembling:

- the inlet pipe is connected to the pump by means of a flange.

The pump for increasing the water pressure in the apartment will be responsible for supplying liquid with the required pressure; - the required speed and pressure are achieved through pipes of a certain diameter.

Water begins to move rapidly to the center of the working container, where the streams are mixed; - speed control is carried out using special devices that are installed on both nozzles of the chamber;

- water, through the safety valve moves to the outlet, through which it returns to the starting point.

Constant movement creates heating of water, heat is converted into mechanical energy.

Heat calculations are done according to the following formulas:

Epot = - 2 * Ekin, where

Ekin = mV2 / 2 - variable kinetic value.

Assembling a cavitation generator with your own hands will save not only on fuel, but also on the purchase of serial models.

The production of such heat generators has been established in Russia and abroad.

The devices have many advantages, but the main drawback - the cost - negates them. The average price for a household model is about 50-55 thousand rubles.

Having assembled a cavitation heat generator on our own, we get a device with high efficiency.

For the correct operation of the device, it is necessary to protect the metal parts by painting. It is better to make parts in contact with liquid thick-walled, which will increase the service life.

In the proposed video, see a clear example of the work of a home-made cavitation heat generator.

Subscribe to updates by E-Mail:

Static Cavitation Heat Generator

This type of heat generator is only conventionally called static. This is due to the absence of rotating parts in the cavitator vortex structure. In order to create cavitation processes, various types of nozzles are used.

For cavitation to occur, it is necessary to provide a high speed of movement in the liquid cavitator. For this, an ordinary centrifugal pump should be used. The pump will build up fluid pressure in front of the nozzle. It will rush into the nozzle opening, which has a much smaller cross-section than the supply pipeline. This provides a high velocity at the exit from the nozzle. With the help of a sharp expansion of the liquid, cavitation occurs. This will also be facilitated by the friction of the liquid against the channel surface and water turbulence, which occur in the case of a sharp alignment of the jet from the nozzle. Water heats up for the same reasons as in a rotary vortex design, but with a slightly lower efficiency.

Scheme of the principle of operation of a stationary heat generator.

The device of a static heat generator does not need high precision in the manufacture of parts. In the manufacture of these parts, machining is minimized compared to a rotary design. Due to the absence of rotating parts, the issue of sealing parts and mating assemblies can be easily resolved. Balancing is not needed here either. The service life of the cavitator is much longer. Even in the case of the exhaustion of the resource of the nozzle, its manufacture and replacement will require much lower material costs. In this case, the rotary cavitation heat generator will need to be manufactured anew.

The disadvantage of a static device is the cost of the pump. However, the cost of making a heat generator of this device practically does not differ from a rotary vortex structure. If we recall the resource of both installations, this disadvantage will turn into an advantage, because in case of replacing the cavitator, it is not necessary to change the pump.

Therefore, it makes sense to think about how to make a static vortex heat generator.

Manufacturing of vortex heat generator Potapov

Many other devices have been developed that operate on completely different principles. For example, Potapov's vortex heat generators, made by hand. They are called static conventionally. This is due to the fact that the hydraulic device has no rotating parts in the structure. As a rule, vortex heat generators receive heat using a pump and an electric motor.

The most important step in the process of making such a heat source with your own hands will be the choice of the engine. It should be selected depending on the voltage. There are numerous drawings and diagrams of a do-it-yourself vortex heat generator, which demonstrate methods for connecting an electric motor with a voltage of 380 volts to a 220-volt network.

Frame assembly and engine installation

Do-it-yourself installation of a Potapov heat source begins with the installation of an electric motor. Attach it to the bed first. Then use an angle grinder to make the corners. Cut them from a suitable square.After making 2-3 squares, fasten them to the crossbar. Then use a welding machine to assemble a rectangular structure.

If you do not have a welding machine at hand, you do not need to cut the squares. Just cut out the triangles in the places of the intended fold. Then bend the squares using a vise. Use bolts, rivets and nuts to secure.

After assembly, you can paint the frame and drill holes in the frame to mount the engine.

Installing the pump

The next important element of our vortex hydroconstruction will be the pump. Nowadays, in specialized stores, you can easily purchase a unit of any power. When choosing it, pay close attention to 2 things:

- It must be centrifugal.

- Choose a unit that will work optimally with your electric motor.

After you have purchased the pump, attach it to the frame. If there are not enough crossbars, make 2-3 more corners. In addition, it will be necessary to find a coupling. It can be turned on a lathe or purchased from any hardware store.

Vortex cavitation heat generator Potapov on wood, made by hand, consists of a body, which is made in the form of a cylinder. It is worth noting that through holes and nozzles must be present at its ends, otherwise you will not be able to correctly attach the hydro structure to the heating system.

Insert the jet just behind the inlet. He is selected individually. However, remember that its hole should be 8-10 times smaller than the pipe diameter. If the hole is too small, the pump will overheat and will not be able to circulate the water properly.

In addition, due to vaporization, Potapov's vortex cavitation heat generator on wood will be highly susceptible to hydroabrasive wear.

How to make a pipe

The process of making this element of Potapov's heat source on wood will take place in several stages:

- First, use a grinder to cut a piece of pipe with a diameter of 100 mm. The length of the workpiece must be at least 600-650 mm.

- Then make an external groove in the workpiece and cut the thread.

- Then make two rings 60 mm long. the caliber of the rings must correspond to the diameter of the pipe.

- Then cut the threads for the half rings.

- The next stage is the manufacture of lids. They must be welded from the side of the rings where there is no thread.

- Next, drill a central hole in the covers.

- Then use a large drill bit to chamfer the inside of the cover.

After the operations done, the wood-fired cavitation heat generator should be connected to the system. Insert a branch pipe with a nozzle into the pump hole where the water is supplied from. Connect the other fitting to the heating system. Connect the outlet from the hydraulic system to the pump.

If you want to regulate the temperature of the liquid, install a ball mechanism right behind the nozzle.

With its help, Potapov's heat generator on wood will run water throughout the device much longer.

Is it possible to increase the performance of the Potapov heat source

In this device, as in any hydraulic system, heat loss occurs. Therefore, it is desirable to surround the pump with a water jacket. To do this, make a heat-insulating housing. Make the outer gauge of such a protective device larger than the diameter of your pump.

A ready-made 120 mm pipe can be used as a blank for thermal insulation. If you do not have such an opportunity, you can make a parallelepiped with your own hands using sheet steel. The size of the figure should be such that the entire structure of the generator can easily fit into it.

The workpiece must be made only of quality materials in order to withstand the high pressure in the system without problems.

In order to further reduce heat loss around the case, make thermal insulation, which can later be sheathed with a sheet metal casing.

Any material that can withstand the boiling point of water can be used as an insulator.

The manufacture of a heat insulator will take place in several stages:

- First, assemble the device, which will consist of a pump, a connecting pipe, a heat generator.

- After that, select the optimal dimensions of the thermal insulation device and find a pipe of a suitable caliber.

- Then make the covers on both sides.

- After that, securely fasten the internal mechanisms of the hydraulic system.

- At the end, make an inlet and fix (weld or screw) a pipe into it.

After the operations done, weld the flange on the end of the hydraulic pipe. If you have difficulties with mounting internal mechanisms, you can make a frame.

Be sure to check the tightness of the heat generator assemblies and your hydraulic system for leaks. Finally, remember to adjust the temperature with a ball.

Frost protection

First of all, make an insulation casing. To do this, take a galvanized sheet or a thin sheet of aluminum. Cut out two rectangles. Remember that it is necessary to bend the sheet on a mandrel with a larger diameter. You can also bend the material on the crossbar.

First, lay the sheet you cut out and press down on top of it with a piece of wood. With the other hand, press on the sheet so that a slight bend forms along the entire length. Then move your workpiece a little to the side and continue bending it until you get a hollow cylinder.

Then make a cover for the casing. It is advisable to wrap the entire thermal insulation structure with a special heat-resistant material (glass wool, etc.), which must be subsequently secured with a wire.