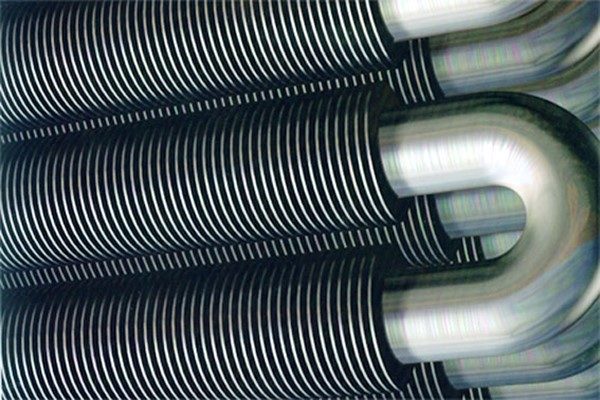

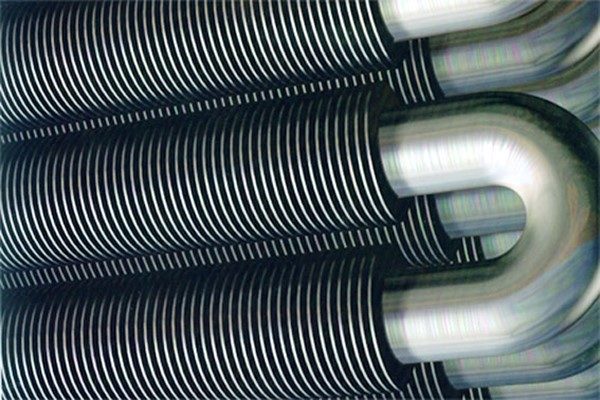

It is impossible to imagine the efficient operation of air coolers without such a detail. Almost every metal service line boasts excellent heat transfer properties. Over time, conventional smooth pipes have been improved. We managed to make a breakthrough in the production of thermostatic equipment. The entire operation of such a device and its effectiveness depend on pipes. Equipped with metal fins, such pipes have a significantly increased heat transfer. They are used both in everyday life and in industry. It is impossible to imagine the device of a modern heat exchanger without such a detail as finned tubes.

- Used in everyday life and in heavy industry;

- Finning promotes heat removal in heat exchangers for freezing gases or heating buildings;

- A heat exchange surface that has no analogues in the world.

Today, it is impossible to imagine a high-quality heat exchange device without such pipes. There are several production technologies and many applications. The way the pipe was produced depends on its main characteristics. This determines the possible range of applications, so you need to choose a product wisely. It is recommended to make a complete calculation of heat transfer in conditions that imply the operation of the pipe.

Finned Tubes Design and Applications

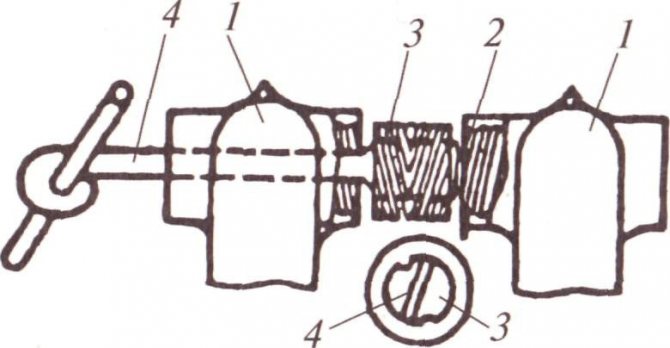

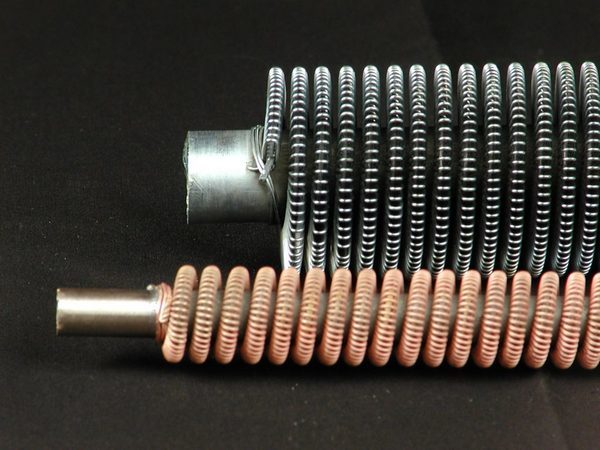

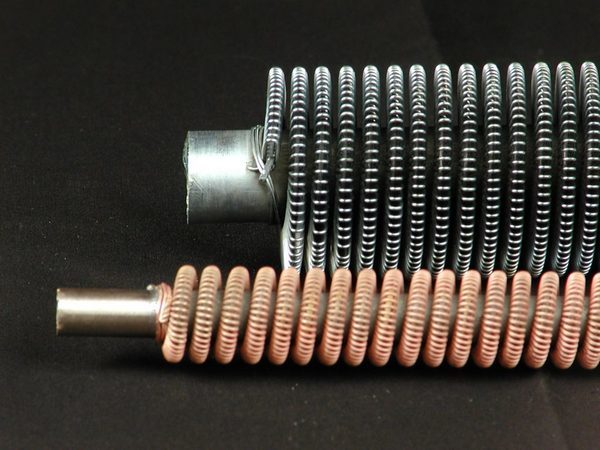

Finned tubes are monometallic or bimetallic structures, consisting of two elements:

- Inner pipe. This is a supporting element, along the inner cavity of which the working medium moves. It is made from metal, most often from steel. Cast iron and non-ferrous metals are used much less frequently. The material from which the inner part of the structure is made is resistant to temperature extremes and high pressure, and has anti-corrosion properties.

- Outer ribs. They can also be made from steel, cast iron and non-ferrous metals. The outer ribs efficiently transfer heat from the carrier.

Finned tubes are used in various fields of human activity:

- the machine building industry uses them in refrigeration units, oil coolers and compressors;

- chemical, oil refining and petrochemical - in condensers, gas heaters and gas coolers;

- nuclear power - in gas coolers, intermediate refrigerators, steam air heaters, drying towers;

- in air conditioning technology;

- in heat exchange units.

Pipes with metal fins are used as cooling, heat exchange and other devices at various facilities

A little about the scope

Finned tubes are extremely popular today. They can be seen wherever a room needs to be either heated or cooled.

As we mentioned earlier, the efficiency of finned tubes is based on the high heat transfer achieved by the design features.

Finned tubes are part of many devices in private homes and factories. In the first case, they are used in air conditioners, since they help in air cooling as much as possible. In the second case, they are used not only for cooling, but also for heating the room, and also help in getting rid of aggressive gases and liquids.

The most popular area of production where finned tubes can be found is mechanical engineering. There they are used in the manufacture of various devices:

- compressors;

- refrigerators;

- electric dryers;

- oil coolers;

- air heaters.

Finned tube production and characteristics

The way of production of products depends on their purpose and related technical characteristics.

Basically, fully automated spiral finning is used, in which a spiral welded with a continuous seam passes around the inner tube. It can be done in three ways:

- Rolling.

- Coiled from aluminum.

- Winding with welding.

Further processing is not required, the product has the following features:

- increased by half the heat transfer coefficient;

- increased resistance to stress;

- maintaining the specified characteristics with increasing pressure, temperature drops and other sharp changes in operating conditions;

- increasing the productivity of the equipment that was equipped with it.

Important! Spiral fins allow to reduce pipe consumption while reducing the weight of the heat exchangers.

Coating the previously degreased finned tube with magnesium oxide and subsequent annealing gives it a heat-resistant coating. Such products have:

- increased by more than one and a half times the heat transfer coefficient;

- increased resistance to various types of corrosion;

- increased productivity;

- long service life;

- increased resistance to pressure and temperature drops;

- the ability to use in aggressive environments.

The method of production of pipes, the shape of the fins and the method of their fastening are reflected in the technical characteristics of the products and determine the scope of application.

Design

Regardless of the material, products of this type are the same in design. They differ only in details - the shape of the petals and the ribbing coefficient. "Construction" is assembled from two components:

- The base is a pipe made of a material with anti-corrosion properties. Its task is to withstand pressure and temperature differences. They use steel, cast iron and non-ferrous metal pipes. Depending on the tasks to be solved, a coolant or a heat carrier flows through them.

- Ribs that are pinned to the canvas. Since heating is carried out over the entire surface of the petals, its efficiency remains the same regardless of the temperature of the carrier.

The ribbing coefficient is a value obtained from dividing the area of the protrusions and the areas between them by an un-ribbed surface. The larger it is, the higher the efficiency.

Cast iron pipes are cast immediately with ribs. For the manufacture of products from other materials are used:

- high-frequency welding of elements;

- crimping washers;

- cross-helical knurling;

- electric arc and resistance welding;

- winding with tension of a metal tape on the base.

Some manufacturers make slotted fins to improve heat transfer efficiency. Rolled aluminum tubes can be used at temperatures up to 350 ⁰C. Structures made with steel tape technology are able to withstand harsher conditions.

Advantages of Using Heat Resistant Finned Tubes

Heat-resistant finned products, obtained as a result of the use of new technologies, have a number of advantages that have led to their widespread use. They differ:

- high manufacturability. The use of resistance welding requires neither a large amount of energy, nor special consumables, nor sophisticated equipment;

- increased intensity of convective heat transfer. In the space of the interfin channels, the flow of the working medium is turbulized, and all sections of the finning work equally well;

- excellent thermal contact between structural member and ribs. The use of resistance welding made it possible to achieve an almost perfect thermal contact;

- lower thermal resistance of thermal transfer.Since the thickness of the condensate film has decreased, the level of condensation of the vapors of the process fluid flowing through the pipeline has also decreased. This is due to the presence of a heat-resistant coating.

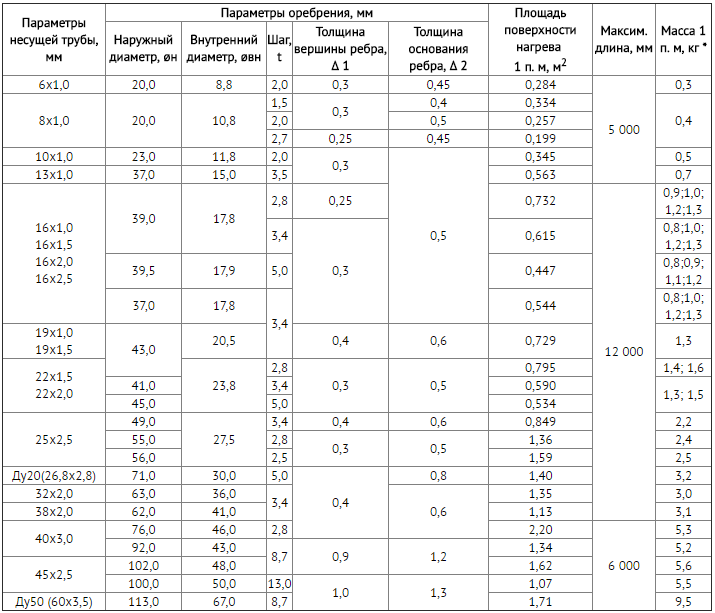

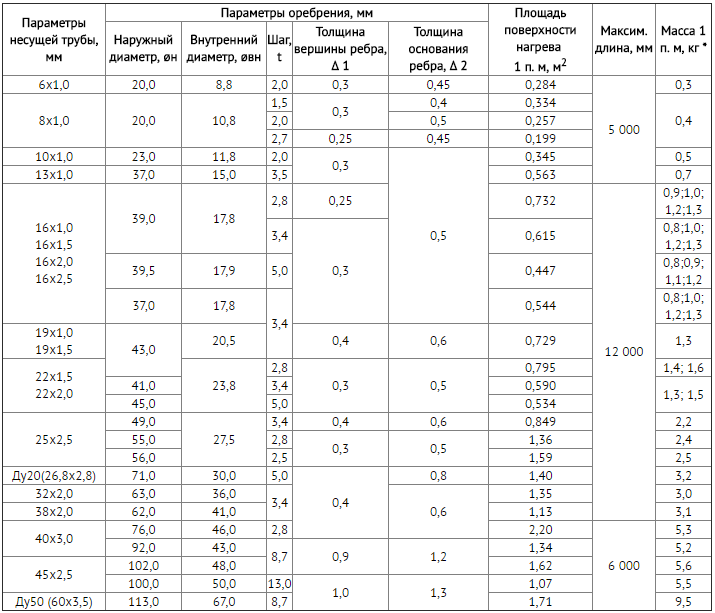

Specifications

Finned tubes have strong advantages over standard products. The equipment is characterized by:

- Low thermal resistance of heat transfer during condensation inside the products of heat carrier vapors. This is due to the reduction in the reduction of the condensate film.

- A high-quality temperature contact between the ribs and the supporting tubular product.

- High intensity of convective heat exchange, as a result of the absence of low-quality ribbed fragments and turbolization of flows in the channels located between the ribs.

- High manufacturability. This is due to the use of modern equipment that provides low consumption of raw materials and energy.

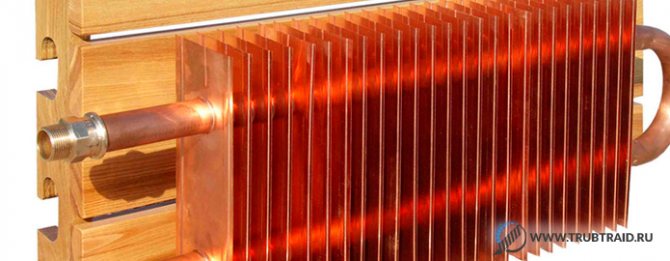

The peculiarity of copper finned pipes is resistance to corrosion processes. Long service life of heat exchangers. The products have a fairly strong resistance to aggressive environments. The most popular is the 10 mm finned copper tube. Below you can familiarize yourself with the characteristics of ribbed copper products of different diameters.

The ratio of the total outside area to the outside area without ribs is called the ribbing ratio. To calculate the performance of a ribbed product, it is necessary to take into account the geometry of the rib shapes, the structure of the tube bundle and the thermal conductivity of the material of manufacture.

Finned cast iron pipe

Technological progress made it possible to manufacture ribbed cast iron structures. This allowed the use of cast iron finned heating pipes. After all, heating systems are literally the ideal environment for using ribbed cast iron products. They have the following advantages:

- high resistance to corrosion caused both by the action of the working fluid from the inside and by the external environment;

- ease of installation;

- high heat transfer coefficient;

- compactness;

- low cost.

Cast iron finned pipes have many advantages, one of them is resistance to high temperatures

Ribbed cast iron products are not without drawbacks. They are:

- tend to accumulate poorly cleaned dust between the ribs;

- weigh a lot;

- fragile under mechanical stress.

Note! The listed disadvantages make it possible to use finned cast iron pipes to create heating registers in production and storage facilities.

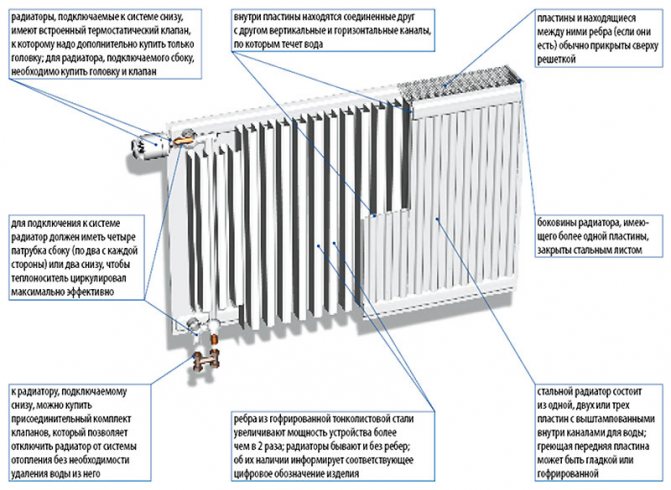

For registers, finned cast iron pipes are specially produced in the form of hollow radiators, sometimes equipped with connecting threads or flanges at the edges to ensure docking with other elements of the heating system.

And cast-iron radiators for residential premises continue to be in high demand, as they can withstand temperatures of one and a half hundred degrees. A cast iron starting pipe is often built into the design of heating systems. Thanks to this, the heating stove heats up the surrounding space faster.

Do-it-yourself pipe finning - how to achieve this

When making pipes with finning on your own, it is imperative to take into account the decrease in the efficiency of the "handicraft" pipe in comparison with factory samples.

Finning a pipe at home can be done in the following ways:

- welding;

- wire winding;

- notch in conjunction with welding;

- threading with a lathe (be sure to make a deep profile);

- notch and tension.

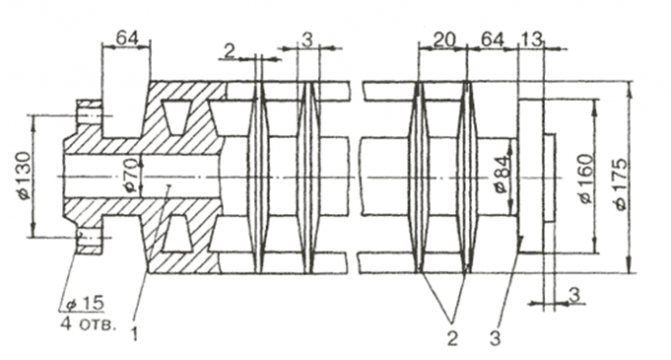

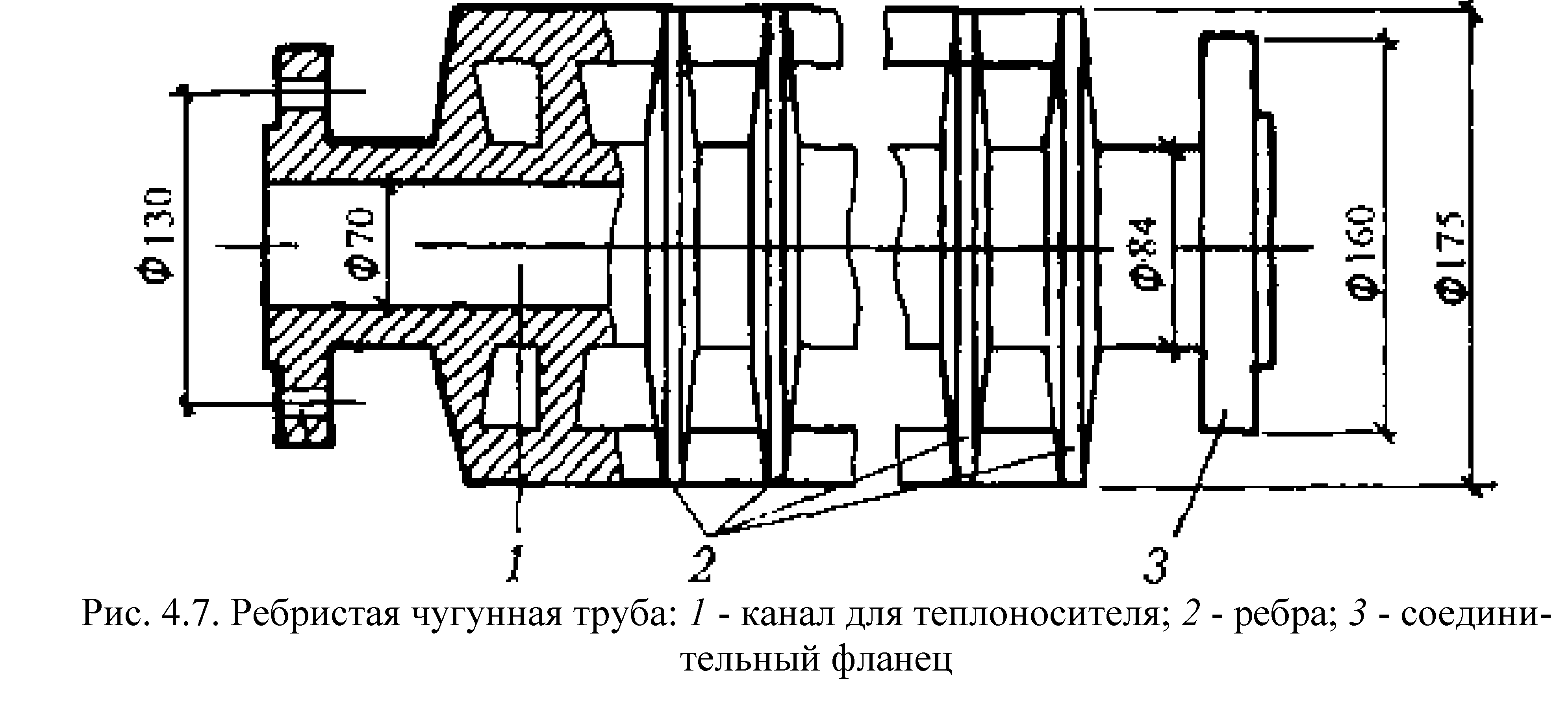

Pig-iron economizer pipe

In the production of industrial heat exchangers, finned cast iron tubes are simply irreplaceable.For industrial registers (economizers), ribbed cast iron pipes are produced either with round ribs or rectangular. The inner diameter is seventy millimeters, the outer one is 175 mm. The large difference between the values of the inner and outer diameters makes it possible to obtain a relatively low temperature on the surface, despite the fact that the coolant will be very hot.

Cast iron pipes most often have a flange connection

Economizer cast iron pipes are sold in lengths of two or three meters. They are equipped with two blind plugs and two plugs with holes - left-hand (marked as "L") and right-hand. The inconveniences associated with the transportation of economizer cast iron structures, heavy and poorly resistant to mechanical damage, more than pay off if they are properly operated. Using economizer elements, it is recommended:

- expose mounted structures to minimal external influence;

- do not allow the temperature of the coolant to be exceeded. Economizer pipes are able to withstand heating of the coolant for a short time up to one and a half degrees, but it is advisable not to raise the temperature above 95 ° C;

- apply a constant working pressure of six to ten atmospheres. Although it is possible to connect to steam boilers with operating pressures up to 24 atm;

- cover the outer surface with a special primer;

- when installing, pay attention to the fact that the distance from the middle axis of the register to the side wall is more than 130 mm, and to the floor - more than two hundred millimeters;

- setting the registers in two rows and connecting them with each other using a special arc, maintain a distance between the median axes equal to 250 mm.

Adhering to the rules of operation, you can achieve the greatest efficiency of the functioning of economizer cast iron pipes.

Application of cast iron ribbed tubular products

Due to their significant weight and low level of aesthetics, cast iron finned radiators are mainly used for steam or water heating of production shops, warehouses, livestock complexes and other facilities of significant areas. At the same time, the single use of such equipment is ineffective, and the elements are installed in sections of several radiators. Such heating registers from a finned pipe increase the intensity of heating the room at times, but at the same time require a significant area for installation.

These devices are also suitable for home heating, but they will need additional finishing in the form of decorative covers or false walls.

The high technical characteristics of cast iron determine the widespread use of cast iron finned tubes in economizers - gases and corrosive substances passing through them do not cause corrosion of the heat exchanger material.

Installation of cast iron finned pipes

Due to the significant weight, finned heating registers place increased requirements on the base. The bearing capacity of the walls (with wall-mounted radiators) and the strength of the brackets must be high, and the fixing of the fasteners into the base must be reliable. With the floor-standing design of the unit device, supports, standard or self-made, must be welded at the bottom of it. If the floor is a wooden flooring, then slots are arranged in it so that the radiator supports are located on the supporting floor slab.

Before installation, the finned radiator is cleaned of old paint and dirt, degreased, and then primed and painted. It is better to paint with a spray gun, since, due to the configuration of the register, the painting area is large, and the ribbing is poorly accessible for working with a brush.

A solution of red lead in drying oil is suitable as a primer, and the finishing layer is heat-resistant paint (enamel) of a suitable color or a solution of aluminum powder. The register to be painted should not be in direct sunlight - the paint will flow.

Important! The finned radiator is installed so that from the floor to the longitudinal axis of its lower register is at least 20 cm, and from the side surface to the wall - at least 15 cm.

After the paint has dried, the painted radiator is installed in place, after which the device is additionally fastened to the wall in order to avoid accidental overturning due to mechanical stress.

Connection to the heating circuit is made after the final installation of the unit, so that its displacement does not violate the tightness of the connections. The insert is made depending on the design of the register branch pipes - flanged, threaded or welded. For a flange connection, it is recommended to use paronite cut to the size of the flange mirrors as a cushioning material (mirrors are cleaned of paint with fine sandpaper), or to use standard gaskets, if they are provided by the package.

After the final installation of the unit, spot painting of areas damaged during installation is performed.

Embossing cast iron pipes

Since the external sewerage networks are made mainly of cast iron, it is impossible to do without stitching and stamping. Stamping is carried out when assembling a system that includes cast iron pipes to seal the gaps that arise at the place where the transition to another cast iron pipe is made. It is produced using:

- Resin sealant and grout.

- A lightly dampened mixture of cement and asbestos fiber.

- Fills with gray.

Important! Making caulking, the pipes are gently tapped with a hammer so that the socket moves freely.

If the flare cannot be cleared, then a gray fill was applied. It is carefully burned out, be sure to wear a respirator. Having released the socket, it is thoroughly cleaned. A sealing ring covered with a special lubricant is inserted into the socket, and a new part is inserted into it.

Types of heating devices

There are three of them in total:

- radiators;

- convectors;

- and devices combining the two previous types.

Radiators are a design designed for large volumes of constantly circulating heat carrier of high temperature.

Their heat transfer is similar to the "fireplace effect", when the surrounding space is heated by radiation.

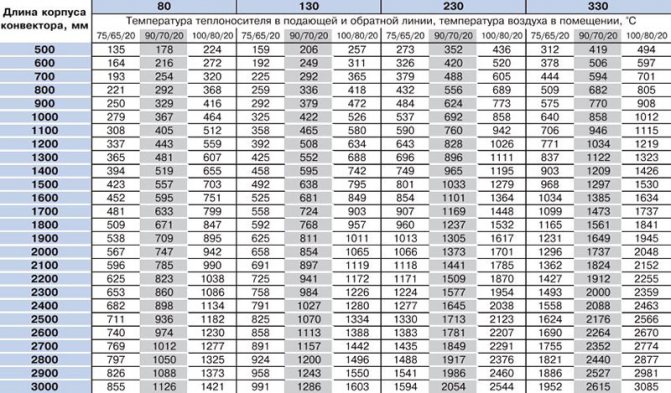

Convectors imply the circulation of air masses.

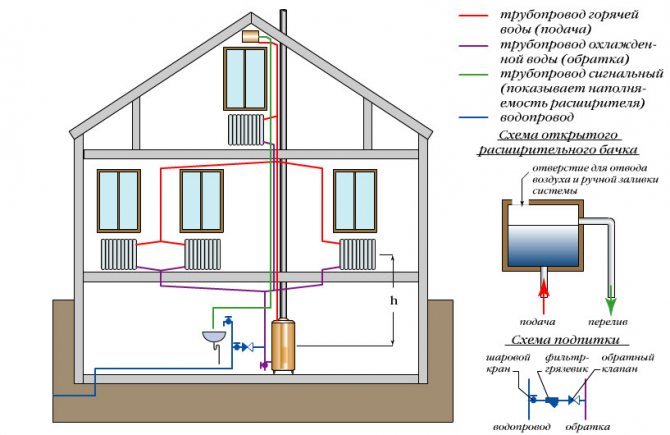

Convectors imply the circulation of air masses. Convector pipes, made in the form of an "accordion", pass a coolant through themselves, which heats them up. Air masses move from bottom to top through the "ribs" and are heated from their many hot surfaces. As already noted, there are heating devices that combine the properties of both convectors and radiators. Such devices are produced by such companies as Korado, Kermi, DeLonghi. These heaters are equipped with storage panels, which receive warm water masses, and it is also necessary to note their ribbed surfaces. Thus, both radiation and convection are realized simultaneously.

DESIGN PRESTIGE LLC

Services for the installation of heating water supply

DESIGN PRESTIGE LLC 8 (495) 744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page by topic heating > resant.ru/otoplenie-doma.html For communication use the contact phone number Holding SpetsStroyAlliance 8(495) 744-67-74, which you can call around the clock. note Our company DESIGN PRESTIGE LLC is a part of the non-profit organization ANO INTERREGIONAL COLLEGE OF JUDICIAL EXPERTS.We also provide services for independent construction technical expertise.Heating from Holding SpetsStroyAlliance View: hot water here> resant.ru/otoplenie-dachi.html