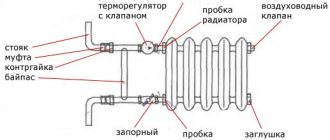

Heating systems do not always have an attractive appearance. This is especially true for old structures, which, even after painting, will look bulky and ruin even the most original interior. In order to cope with the problem, radiator grilles are used. They come in different colors and sizes, differ in structure.

What is a radiator grill?

In another way, the product is called a box. Battery grilles are an important part of the interior. They allow you to hide old batteries and complement the design of the room. There are several reasons (besides aesthetic) why people put grilles on radiators, for example, products save on heating costs. The area of the grates is evenly warmed up, and they distribute heat energy throughout the room. It should be noted that the style and design solutions of the grilles do not in any way affect the technical characteristics of the radiator.

What does the radiator grill consist of?

The design of the products can be different. The grille for heating radiators is a surface with protrusions on the sides. They have fixing elements. With the help of these devices, the grille is mounted on the radiator. The product is available with or without a top cover. There is one common design feature for all radiator grilles - they do not have a hole on the surface or below.

avtocosmetic24.ru

Tweet

Greetings dear fan of car tuning :) If you are reading this article, then you want

make tuning of the radiator grill for your iron horse. At first glance, it seems that making such a lattice is quite simple, cut out the excess, inserted the grid and you're done! But it was not there! The shape of some standard radiator grilles does not allow us to make what we want out of them, and not everyone wants to "spoil" a standard part, so we will do do-it-yourself radiator grill made of fiberglass, without prejudice to the standard. By the way, you can then sell it and recoup your costs for the purchase of materials.

Well, now let's get down to business!

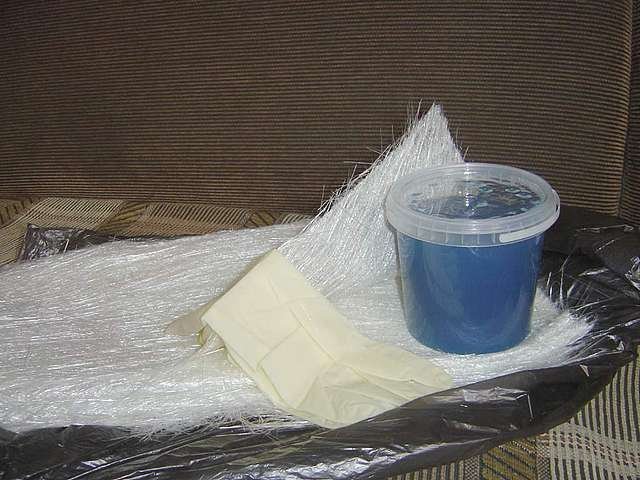

For the manufacture of a radiator grill, we need a certain list of materials:

* Polyester resin in a quantity of 200-300 grams + hardener. But most often it is sold in containers of at least 1000 grams.

* Glass mat with a density of 300-450 g / m2, in a quantity of 500 g. or 1 running meter.

* Thick cardboard

* Masking tape

* Universal putty

* Sandpaper with grit from P 40 to P 320 (Convenient)

* Grout Bars

* Acrylic primer

* Thinner and Degreaser

* Well, various little things (screwdrivers, keys, bolts, spatula, etc.)

Manufacturing of the Matrix.

To make a brand new fiberglass radiator grill, we need to make a matrix or frame of the future product. As a frame, we will use the stock radiator grill. But this is not necessarily always the case. Depending on your imagination and the design features of the car, the initial frame can be, for example, a car bumper, optics, and the addition of various materials (cardboard, foam, plasticine, wood) to this composition.

As I said, I took the old radiator grill as a basis. That's actually it.

After removing the grill from the car, we need to make a matrix for the future product. In the picture below, with a pencil, I outlined those parts that need to be pasted over.Attention!!! Before working with composite materials, be sure to cover the part well with tape. To do this, it is better to use two types of adhesive tape, masking tape and regular transparent. For what??? In the process of polymerization of materials, a chemical reaction occurs, which is accompanied by heating of the materials. Once I have already encountered such a phenomenon in the manufacture of eyelashes for headlights. The work resulted in damaged headlights. Therefore, learning from these mistakes, I experimented and came to the conclusion that if you first stick transparent adhesive tape, and then paint on top of it, then nothing will happen to the surface of the plastic or paintwork.

Fiberglass production.

The base from which we will make a new part is ready. Now we need to glue the fiberglass. To do this, we take a polyester resin and dilute it with a hardener in the required quantity, observing the proportions. Let me remind you that dilution proportions of polyester resin are 2: 100, i.e. per 100 gr. polyester resin, you need only 2 gr. catalyst (hardener). It is necessary to strictly adhere to these proportions, otherwise you can ruin everything !!!

Glass mat it is necessary to apply in 2-3 layers, if you use the 300th, 450th is enough to put in 2 layers.

Now we are waiting for the product to dry. This time will average 2-3 hours at a temperature of 18-25 degrees.

When the part is ready for further processing, it must be separated from the radiator grill. We should have a "frame" that needs to be finalized! With the help of a grinder, we cut off the excess fiberglass and install the part in place. Already in place, we will refine the matrix. As I said above, you can use anything you like to form a matrix. But in my case, cardboard was perfect for this, since the shape of the lattice is quite simple and I just need to add a small side in a circle. See the photo.

The cardboard must be glued from the back, and glass mat must be applied from the front. One layer of 300 glass mat will suffice here. Because if you apply several coats, the part may get too thick in some places. But even for rigidity, one layer of 300 glass mat will not be enough. So what can you do? This moment can be eliminated by gluing an additional layer on the reverse side. Of course, from the inside, all this may look clumsy and not aesthetically pleasing, but do we need this aesthetics in those places where no one sees? I think the answer is obvious.

We glue the "shelf".

Close-up))

Well, almost a new one is ready radiator grill for Honda Domani.

By the way, after work, I advise you to soak the brushes in a container with a solvent, so that they can be reused.

And do not forget to use rubber gloves, as it will be very, very difficult to wash off the resin!

Processing and puttying of the part.

After drying, fiberglass part, you need to align and prepare for painting. But first, you need to trim off any excess and make sure that all the gaps are even and the same. Be sure to install the grille on the car and compare all the slots, corners and roundings. If somewhere, and this sometimes happens, you cut off the wrong thing, then do not worry, with fiberglass it is very easy to solve. Dilute the required amount of resin again and glue the desired piece. It is very convenient to adjust the gaps in this way. I also want to say that it is very convenient to make rounding and align the boundaries of the part with the help of a flat bar.

The plane of the part itself, it is also necessary to prepare for the application of the putty.

To do this, use coarse sandpaper, grit P 40-60, it copes best with such tasks.After processing fiberglass with coarse abrasives, various small pores and irregularities will remain. We have prepared a universal automotive filler for them.

Before applying it, the surface of the fiberglass part must be cleaned of dust and be sure to degrease.

The putty is also diluted with a hardener, determine the amount of putty and hardener "by eye". There are no clear proportions for using the hardener. The most important thing is to stir the materials thoroughly so that there are no clear, red clots in the filler mass.

The applied first layer of putty should be treated with P80-120 sandpaper, for subsequent layers, it is necessary to use finer abrasives.

After leveling the surface, little remains to be done ... ...

Manufacturing of fasteners.

In this case, there were no difficulties with the mounts. At the top, the grille is fastened with 5 plastic clips, and at the bottom with a couple of latches, which, of course, we could not repeat. Well, it doesn't matter, the grille holds very well without them.

Part priming and painting.

I will not describe in detail this process, since we have a topic making a radiator grill with your own hands, not painting lessons.

When the ground is dry, I advise you to reinstall the radiator grille on the car, so that you can see how it all looks "in color". Thus, you can see any joints that are not visible in the draft.

And in the end what we did.

Here, of course, in comparison with the previous photo, a lot has been done besides the radiator grill. By the way, there is now a standard radiator grille, which, if necessary, can be installed back on the car.

Have you read the article about making a radiator grill with your own hands from fiberglass!

I wish you success!

I recommend reading:

Manufacturing of fiberglass products. Making a new podium for tumanki.

Car door sill repair. We treat rust with fiberglass.

Mazda surname Tuning the trunk lid.

What are radiator grilles for?

The main function of the products is decoration. Decorative grilles for heating radiators give the space with a heat exchanger an aesthetic look. Another purpose of the structure is to heat the room, therefore, for the production of products, those materials are used that conduct heat well. It is worth remembering that the grilles can trap 5 to 25% of the heat coming from the batteries. This is both good and bad. For example, if the room is hot, the grates will help normalize the indoor climate.

In addition to even distribution of heat and aesthetic functions, the grille has another purpose - a protective one. It prevents contamination of the radiator. The batteries are difficult to clean (especially cast iron), and the grate is easy to care for. The protective structure will be relevant in those homes where there are small children. There are no sharp corners in it, so babies will not be injured if they come into contact with it. In addition, the products save children from thermal burns.

Features and sizes of decorative grilles

To begin with, we will deal with the functional and specific features of screens for heating batteries, and only then we will proceed to consider the instructions for their manufacture. So, decorative lattices are responsible for several tasks at once:

- Radiator masking. If you need to effectively hide the batteries, but at the same time not provoke a decrease in the quality of heating, then decorative screens are an ideal option: they will decorate radiators in an original way, but they will not interfere with the full movement of heated air masses from the heat source to remote areas of the room.

- Protection from dirt. The grill is not only beautiful, but also convenient: it protects the batteries from dust and dirt, thanks to which the maintenance of heating devices does not cause trouble for households.

- Battery safety guarantee. The screen can rightfully be considered not only decorative, but also protective, because it protects household members, especially children, from blows and burns from contact with radiators.

Decorative grill can be an interior decoration

Moving on to the specific features, we immediately note that in this regard, the lattices do not know any restrictions: they can have completely different shapes, colors, textures, dimensions. True, the generally accepted size ruler still exists:

- 60x30 cm;

- 60x60 cm;

- 60x90 cm;

- 60x120 cm;

- 60x150 cm;

- 60x180 cm.

As for the materials from which decorative grilles are traditionally made, here we can confidently single out the three most popular options.

Types of radiator grilles

Buyers are offered an extensive selection of systems that differ in parameters, appearance, design, materials and other parameters. Before deciding on the choice of the best option, it is necessary to determine what tasks the equipment performs, what features the room has and, finally, what the buyer wants.

Radiator screens are divided into three types:

- Suspended structures

... They are used to disguise unpresentable cast iron batteries. Such decorative structures can have from one to several sections, sometimes with a lid on top. The screen for the radiator is attached either with hooks, or simply superimposed on the ribs of the cast-iron battery. - Flat structures

... They will find their use if the battery is in a niche. Such radiator grilles are also called front grilles. Outwardly, they look like rectangular frames with a decorative lattice inside. When choosing a screen with a flat design, it must be borne in mind that they are mounted with an overlap. Flat designs are a suitable option for making radiator window sill grilles. - Protective mesh on the radiator grill

... This option is used in cases when it is necessary to mask the heating batteries that are located along the walls. Such screens serve as an additional source of decor. The main disadvantage of the protective box is the fact that, due to the design features, 40-50% less heat gets into the room.

Types of battery grids and when it is best to use them

The radiator grill can be flat. This option is suitable if the radiator is installed in a niche. Then the whole problem is to find a suitable decor and size (you can still make or order). The mount can be on self-tapping screws (screwed in at the corners), magnets, clamps.

Flat wood grille for radiators hidden in a niche

Most often, a flat lattice is made in the form of a solid wood frame, on which the lattice itself is fixed. Moreover, modern trends are such that gratings are actually made of wood: strips that intersect at different angles, with different steps and frequencies. And this is understandable: wood carving is purely manual work, and one can only imagine how much such beauty will cost. But the grilles made of MDF, and recently from HDF, can be very decorative.

Decorative grilles can be hinged. In this case, they have hooks with which they cling to the top of the radiators. This option is good if the window sill protrudes strongly beyond the battery or the box cannot be made because it becomes too cold (it greatly reduces the efficiency).

Mounted models are easiest to mount

The third option for decorative grilles is a panel with a cover. Moreover, it is desirable that the lid is also patterned or lattice. This requirement is not so much an aesthetic (although this is also), but more from the field of practice: in order for the room to warm up normally, it is necessary for the air to come out freely from above. Otherwise, most of the heat will go to the return pipe. If you have an individual heating system, it is not critical, but if it is centralized, it is uneconomical.You pay for all the heat, but most of it goes away.

The grille for a heating radiator with a cover can, like the previous version, be hung on the heater, or it can be mounted on brackets or awnings to the wall. Even if you are going to mount to a wall, do not make the connection permanent. The battery needs soap from time to time, sometimes you need quick access to it (usually in cases of malfunction). So think over the connection so that you can quickly remove the structure.

This design can stand alone

The next option is a grid battery box. She can stand on her own. And here, too, there may not be a cover: the front grille and sidewalls cover the radiator, and the window sill serves as the cover. In this case, for normal convection, there should be rather large openings under the windowsill and below the floor.

If the radiator is not under the window, but separately, it is often also closed with a box. But this option does not look very aesthetically pleasing. Instead of hiding and decorating, it grabs attention. Moreover, it does not carry any other functionality. Just a box leaning against the wall.

If there is no other option, arrange the radiator box in the form of a small chest of drawers or cabinet. And you can make a stand on which decorative gizmos of a small mass will stand.

If you close the radiator, then so as not to draw attention to this

What are radiator grilles made of?

The list of materials that are used for the manufacture of structures is large, it can be plastic, wood, metal, MDF, glass, wood. The choice of radiator grilles is limited by the design solution, colors, functionality and cost of the product.

Plastic radiator grill

This is the cheapest kind. You can pick up plastic radiator grilles for heating different in color and size. The price of such a product is not high, but it can imitate almost all known decorative surfaces. It is better to use plastic screens in non-residential premises, since when heated they can emit substances hazardous to humans.

Wood radiator grill

This type is one of the most purchased. The main reason for choosing wood grilles for a radiator is the environmental friendliness of the material. A wooden battery screen cannot be cheap. Special impregnations and treatments against dampness and drying out, difficulties in manufacturing - all this increases the cost of products. The thermal conductivity of wooden battens is low, so it is better to install them in houses with a very warm microclimate.

In small rooms, such lattices often perform not only a decorative function, but also take on the role of missing furniture. For example, a table under the window. The lathing made of an expensive type of wood (oak, ash) can be made in the form of rattan or wicker and represent a real work of art.

Radiator grill made of MDF

Products made from this material are durable. They are not susceptible to swelling or drying out. A screen for a radiator made of MDF is more environmentally friendly than plastic, but of lower quality than wooden screens. In appearance, such structures are not much different from natural wood, but when heated, they can emit fumes of glue used to press sawdust.

Metal radiator grill

The most practical are structures made of metal. The facade of such a grill is perforated for better air circulation. The main advantage of such gratings is their high thermal conductivity. This means that such a grill will give maximum heat to the room. In terms of thermal conductivity, metal panels rank first among other types.

The inner surface of the metal grilles is specially painted black to further increase the level of heat radiation.The advantage of such a screen is that it does not emit harmful substances when heated, like a lattice made of MDF, and does not deform like a wooden screen. Forged metal grilles for heating radiators are now widespread.

Glass radiator grill

Recently, tempered glass products have become increasingly widespread. So far, these are the most expensive heating grilles on the modern market. These screens are custom-made and come in a variety of decorative styles. Modern technologies make it possible to apply all kinds of images, engravings, and so on on the surface of such screens.

What materials are used

Metal or wooden gratings are most often hung on batteries, MDF products are quite common, and HDF carved products began to appear more and more often. In this article, we will talk about made of wood and wood materials, and read about metal screens here.

Wood

In a suitable interior, wood always wins. She brings a sense of calmness, reliability and comfort. When is a decorative wood lattice appropriate? When there is at least one more element made of wood. For example, it will perfectly match the floor, even better if the room is finished with wood panels. The combination will look great: a wooden floor, wooden doors and a decorative radiator grille in the same style and color.

Wood is always in trend

Even if the window frame and window sill match at least in color, it already looks harmonious.

Only the doors can match in color, and then the nearby wooden grill that covers the heating radiator looks organic.

MDF and HDF

But wood is not cheap pleasure. In our country, it is more affordable than, for example, in Europe, but still, the cost of quality products is high. Moreover, these products are rarely made from pine: it does not tolerate heating in the best way. Most often they use alder, linden, beech or oak, which are not cheap in themselves. For those who have the skill of working with wood, it is advisable to do everything yourself. Then the price will not be so high. For those who are not very friendly with carpentry tools, there remains a budget option: grilles made of MDF or its improved version of HDF.

New HDF makes very decorative things.

Let's make a reservation right away that MDF does not contain any extraneous binders. It is obtained by pressing at high temperature and pressure of shredded wood waste. At high pressure and temperature, lignin is released from the wood fibers, which binds the particles together. Therefore, the material is considered safe: the level of formaldehyde emission is the same as that of natural wood.

MDF is not afraid of moisture and heat. Not bad for battery cover grids. It is easy to process, can be enameled or laminated. It is often used to create laminate flooring. By the way, such a pair - a laminate on the floor and an MDF grill for a radiator - is a great combination. And last but not least, durable, easy to clean and inexpensive.

Here is such a flat grille of their HDF

HDF is produced in almost the same way as MDF, only at a higher pressure. As a result, the material is thin - the standard thickness is 3-4 mm, with a uniform structure and density. It holds its shape stably under temperature influences, tolerates high humidity. Its surface is very smooth, well laminated, varnished, painted. Therefore, the material is increasingly used in the furniture industry. High density allows you to create decorative openwork lattices using laser cutting.

Rattan

There is another type of natural material, from which light decorative grilles for a heating radiator are often made. This is rattan. A lattice is woven from it, which is then fixed on the frame. The result is a stylish, lightweight design.

Radiator grille dimensions

In order to understand which panel to choose in size, it is worth considering the length and width of the battery. Pay attention to where it is located: under the window, in the wall opening, and so on. Very often, radiators are hidden in a special niche under the windowsill. In this case, the radiator grille must match the dimensions of the box recess. Experts advise you to select the appropriate product dimensions as follows:

- so that the grille is 16-20 mm longer than the radiator;

- so that the distance between the screen and the panel surface is no more than 20-25 cm.

Only if all conditions are met can effective convection air flows in the room be created. An important condition that is taken into account when choosing a grille of a suitable size is that it should have minimal contact with the radiator. In this case, heat loss is reduced, and the panel itself heats up less. In stores, you can buy products in standard sizes (they depend on what material the product is from). If they do not fit the heating system, then you need to make an order for the creation of gratings according to individual dimensions.

Radiator grille design

Manufacturers offer a wide range of decorative battery panels. They differ in design and cost. Let's take a closer look at what decorative designs are used to decorate a room:

- Screen for battery hinged type made of wood

... They fit perfectly into the interior of the kitchen, create an atmosphere of warmth and comfort. The materials used to create these panels are beech, cherry and ash. You can also use a cheaper option - gratings and MDF. A significant drawback of such systems is their high cost. - Metallic decorative mesh

... They are made from steel and aluminum. Popular patterns on the mesh are rhombus, carved ornaments, or notches. However, they are not resistant to corrosion processes. - Tempered or stained glass products

... Decorative patterns are applied to the surface of the grill and it becomes an unusual protective element for the battery.

Diy radiator grill

Anyone who knows about the principle of operation of a radiator and the laws of thermal physics can independently make a design that reduces or increases heat transfer from the heating system. Metal is best suited for such purposes. Consider how a decorative radiator grill is made in stages:

- Take a metal mesh and a sheet of fiberboard. Materials are suitable for making a box with a lid on top and legs on the bottom. Chipboard sheets will be used to create the sides of the product.

- The workpieces are sawn so that they fit the battery. For good air exchange, add 3-8 cm to the length and width of the radiator.

- The sheet metal mesh is cut according to the calculated parameters.

- The facade and the panel are fastened together with a construction stapler or small nails. It is desirable that all connecting elements are on the inside of the frame.

- Collect the box using corners and screws. If you need to increase the heat transfer from the radiator, then a metal sheet is installed behind it.

Radiator grille assembly

Getting the job done is easy. The radiator grill is assembled in several stages:

- Mark horizontal lines so that the box is level. This is done using a conventional or laser level.

- Use a pencil or pen to mark the places where the holes for the screws or plastic dowels will be located.

- Make holes in the wall and remove dust residues from them.

- Insert plastic dowels into the finished holes until they stop inside.

- Cover the edges of the hole with glue or resin composition.

- They begin to install the screen itself. Its hinges are aligned with the previously made holes and screws are inserted. So the whole structure is firmly fixed.