The idea of how to make an electric boiler with my own hands came to me after buying a non-gasified summer cottage. There are 3 worthy models for manufacturing - these are heating elements, electrode (or ionic) and induction boilers. I tried all these options and now I will tell you about the intricacies of self-assembly of these boilers.

A homemade electric boiler is a good alternative to central heating.

Cooking the tool

Before making any electric boiler, you need to take care of a good tool - this is perhaps the weakest point. It is not difficult to assemble the units themselves, but, for example, it is unrealistic without a welding machine.

It is not realistic to assemble a good home electric boiler without a welding machine.

- Welding machine - it is better to take an inverter welder (the price starts from 4700 rubles);

- Cutter - you need to be able to work with a gas cutter, so for home use, take plasma models (price from 4300 rubles);

- Bulgarian - it is desirable to have 2 grinders, a large one for a 230 mm disc (price from 2800 rubles) and a small one for a 125 mm disc (price from 1800 rubles);

- Electric drill;

- Calipers;

- A hammer;

- Kern;

- Roulette.

Option number 2. Making an electrode boiler

The electrode boiler is a more progressive development. Such heaters began to be widely used in the last 10-15 years.

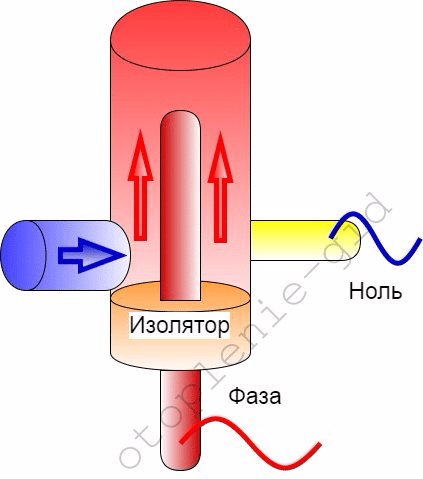

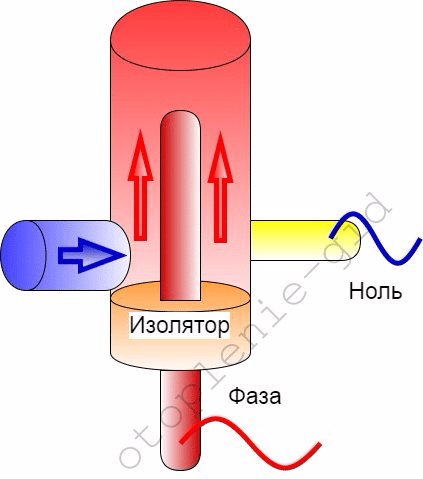

Electrode boiler device

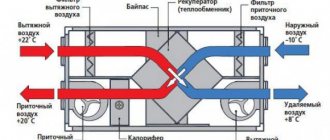

The water itself is used as a heating element in the electrode boiler. The boiler is a metal body, into which a steel electrode insulated from the body is inserted.

A phase is connected to the electrode, and zero to the case, when voltage is applied, the water ions begin to oscillate at a frequency of 50 hertz, as a result of which the liquid heats up. That is why such aggregates are also called ionic.

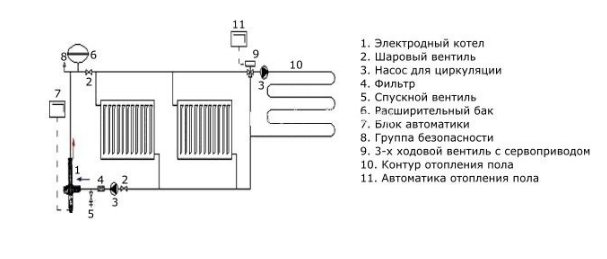

General diagram of the electrode boiler.

The dimensions of such units are small, a pipe with a diameter of up to 320 mm and a length of up to 600 mm is used as a body, but this is the maximum, for private houses ion boilers are made almost half the size.

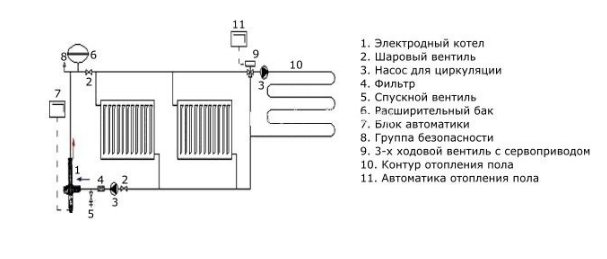

Diagram of a heating system with an ionic boiler.

Dignity:

- Quite modest in size, this boiler will not interfere even with the local heating system of a small apartment;

- In these heaters there is no "dry running", that is, without water, the boiler will simply stop working, but nothing in it will burn out;

- The system is not afraid of voltage drops;

- Heats up quickly and also cools down quickly, which means it is easy to adjust;

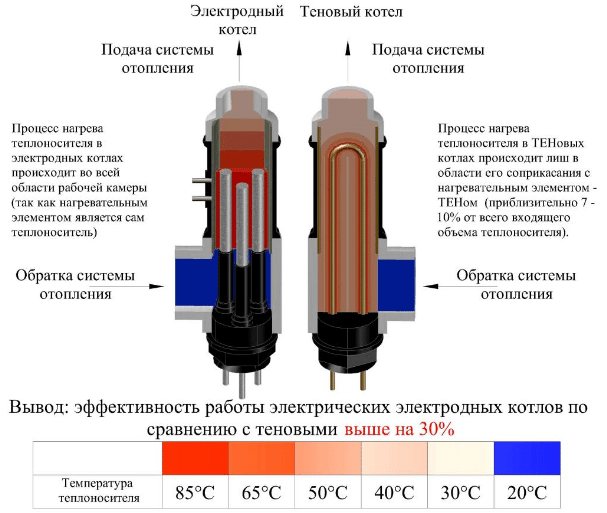

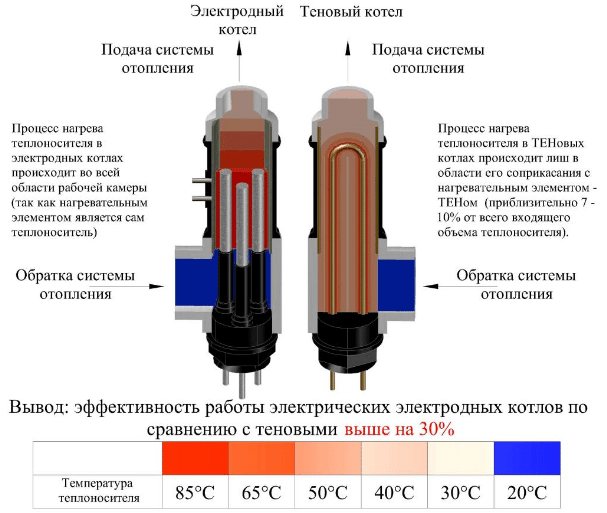

- Compared to units powered by heating elements, the electrode boiler is much more economical.

Electrode boilers are much more economical than heating elements.

disadvantages:

- Ionic boilers are very demanding on the quality and level of electrical conductivity of the coolant;

- Due to the increased risk of electric shock, the devices need reliable grounding;

- When air enters the system, the electrodes actively corrode and quickly become unusable.

We collect the ionic boiler

| Illustrations | Recommendations |

| Body material.

|

| We adjust the branch pipe. One branch pipe will be welded from the side, the second from the end of the pipe. First, we need to trim the side pipe so that it fits snugly against the body of the pipe. I cut the pipe with a grinder, and then brought it to perfection with a round file. |

| Cut a hole. At that time, I did not have a plasma cutter, so I had to nibble the pipe around the circumference and drill 5 mm holes. |

| Adjusting the hole. Then, with the help of a natfel and a round file, the circle is brought to the ideal. The distance from the edge of the pipe to the side branch pipe is 10–15 mm. |

| We weld the pipes. The pipes must first be tacked by welding in several places, so as not to lead, and then scald the seam. |

| Cut out the platform. As a platform, I used a sheet of fiberglass with a thickness of 20 mm, an approximate size of 120x120 mm, I cut it with a hacksaw for metal. |

| Preparing the platform. Drill 5 holes in the platform, 1 in the center and 4 along the perimeter (as in the photo). Hole diameters 10–12 mm. A steel electrode will be attached through the central hole, and the side holes are for fixing the boiler drum. |

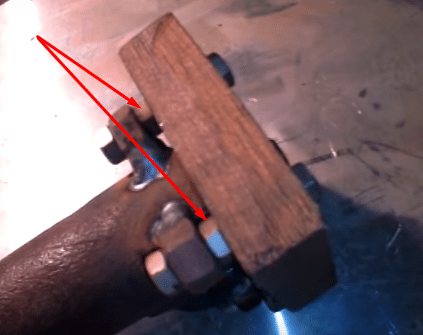

| Attaching the body to the platform. In order to firmly attach the boiler body to the platform, I welded 12 mm nuts on 4 sides. Bolts of 10 mm easily pass through them. But these "ears" should be slightly raised above the platform, to ensure this gap, I screwed the "native" nuts on the bolts from below and fixed the holders with the same nuts from above. Rigid ears are easier to weld on. |

| Boiler assembly.

|

A little more difficult ...

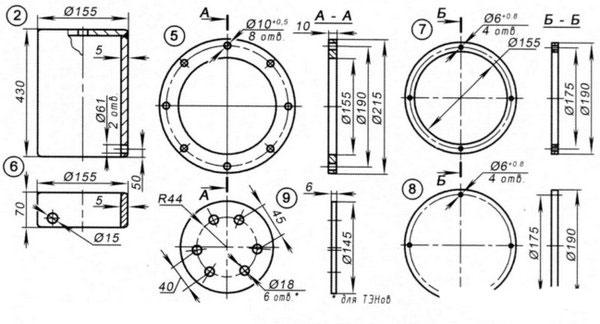

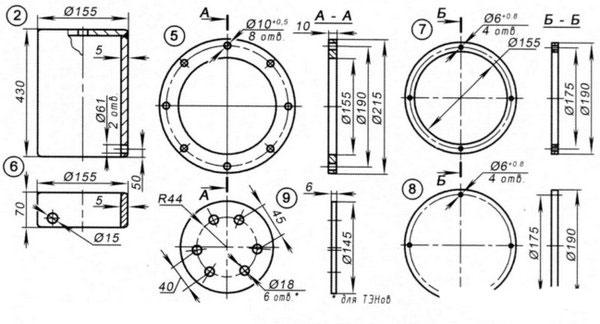

Homemade boiler drawing

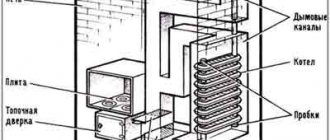

Despite the availability of alternative ways of using electricity in heating systems, a full-fledged boiler still remains the best option. The boiler body is best made of steel. This choice is justified from the point of view of safety, durability of the structure, as well as ease of manufacture. You can create a body using a conventional welding machine. Such work will not require any serious special skills.

Do not make a large case. The more compact the boiler is, the more efficiently it works. What to do if the house is large and you need a unit, the power of which will allow you to heat a large amount of water? Refuse the electric boiler in favor of a different type of equipment. Electrical appliances are suitable for heating a small country house, but when heating large cottages, they will not be the best choice.

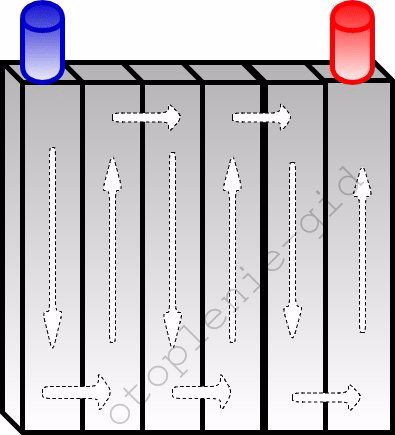

The body can be of any shape, but it must be sealed on both sides. Two holes are made on both sides. Through one, the coolant is supplied to the system, through the other, cooled water enters the boiler.

Heating element

Types of heating elements

The biggest difficulty in the manufacture of an electric heating boiler is to choose the right heating element. Its power should be enough to heat the coolant and water in the hot water system (if necessary, equip it). The power is selected based on the calculations performed. When designing a hot water supply system, it is better to choose a heating element with high power indicators.

The heating element is installed in the housing on the lower cover, opposite the hole through which the cooled coolant is supplied to the heater. It is worth installing shut-off valves in the pipeline next to the boiler in order to ensure the maintainability of the device. Shut-off valves will allow you to turn off the boiler, if necessary, without draining the water from the system. As a rule, heating systems with an electric boiler are made with forced circulation, which will also require the connection of pumping equipment.

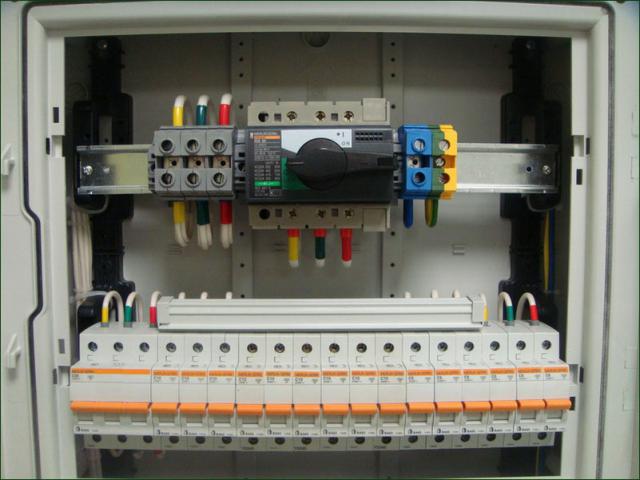

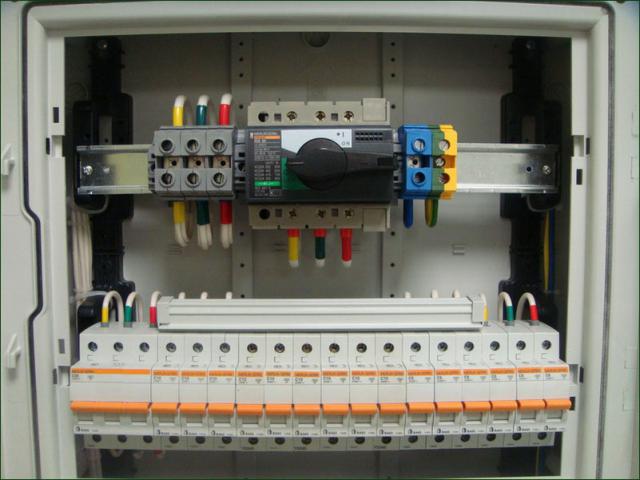

Electrical panel

The operation of electrical equipment is provided by the energy of the mains. To connect a homemade device to the latter, you will need to design an electrical panel. You will definitely need to connect a three-phase input... It is better to entrust this part of the work to a qualified electrician, since the cost of error is disproportionately high.

A starter, automatics, relays, electrical device controls are installed in a metal shield. The system must be grounded. The effectiveness of grounding should be checked annually by employees of specialized organizations. The data obtained by measurements is necessarily recorded in the protocol. The simplest way to perform grounding is as follows. Under the floor is a structure made of a bolt welded to a metal pin. An electrical wire from the shield is screwed to the bolt. As you can see, everything is simple.

Factory electrical panel

The electrical circuit of the device will include the following elements:

- Machine.

- Magnetic switch.

- Control buttons.

- Toggle switch and relay.

- Circuit breakers.

- Thermal sensors.

- Additional automation (if necessary).

After connecting to the mains, you can start the boiler for the first time and test the system.

Option number 3. Induction boilers

Of the widely used models, the induction boiler can be considered the latest development.

How induction heaters work

If you do not go into the intricacies of the device, then an induction boiler is the same microwave oven, the coolant is heated by a magnetic field.

The heating system scheme implies operation at a given time interval.

Dignity:

- Safety;

- High efficiency;

- Any coolant can be used in these units, its quality does not matter;

- In induction boilers, there is practically no scale formation.

disadvantages:

- The cost of induction boilers is quite high;

- These devices have relatively complex control automation. It is problematic for an amateur to assemble it with his own hands.

Putting together a simple induction heater

When I began to study homemade induction heaters, I realized that the instructions there are not simple, and the drawings are quite complicated for a home craftsman, but there is an interesting solution, which I will tell you about later.

| Illustrations. | Recommendations. |

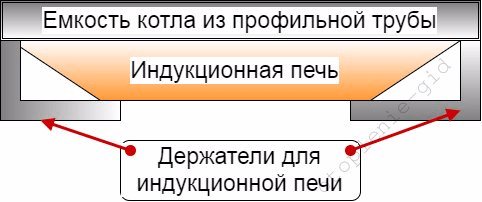

| What the boiler consists of. To assemble such a boiler, you need to buy an induction stove with a power of 2.4 kW (it costs about 2,000 rubles) and 3 m of a profiled pipe with a section of 25x50 mm with a wall thickness of 2.5 mm. |

| Principle of operation. We need to build a kind of flat container from a profiled pipe through which water will circulate. Then attach an induction stove to this container and turn it on. This is the same as putting a pot of water on top of the stove. |

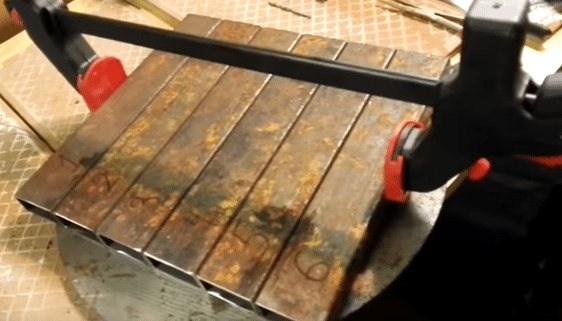

| We cut the pipe. The most difficult thing in this work is to do everything as accurately as possible. I cut the pipe with a miter saw on a stop bed. In my case, the pipe was cut into pieces of 400 mm, after which I cleaned the edges from the burrs with a file. |

| Capacity diagram. As shown in the diagram, water circulates like a snake through this improvised radiator. It was not by chance that I made exactly 6 registers, so I will have the supply and return on one side and the stove will be easier to connect to the heating system. |

| Cutting the connecting holes. The connecting holes must be clearly opposite each other. In this case, I drilled 2 holes along the edges with a 10 mm drill, and then cut out the middle between them with a small grinder. |

| Pipe numbering. There is a very important point: profiled pipes are not perfectly symmetrical, on the one hand they are slightly rounded, and on the other they are even. If you look closely, you can see it in the photo on the left. So, we need to initially fold the sharp edge of the pipes with the blunt one. In order not to be confused later, the pipes are immediately numbered. |

| We collect capacity. Now we need to boil all the seams between the pipes, for this we lay them out on a perfectly flat surface and tighten them with a clamp. Further, so that the stove does not lead, first we grab all the seams pointwise, and then we weld the seams thoroughly. |

| We close the end of the container. To weld one side of the container, I cut out a strip.The strip was cut from the same profiled pipe, I simply cut off one of the sides with a grinder. We weld as usual, first we grab it, then we scald it. |

| We weld the pipes. On the reverse side, we do almost the same thing, with the only difference that the inflow and return pipes are welded to the extreme pipes. The contact area of our metal container with the induction stove should be as large as possible, so the welding seams must be cleaned with a grinder. |

| We mount the guides. In order to hang this whole structure on a vertical wall at the back, we weld 2 corners, into which our induction stove will then be inserted, as in a niche. |

| Painting. At the end of the welding work, I painted the entire structure with heat-resistant paint and welded on the hinges for hanging our induction boiler on the wall. In principle, that's all, now you can connect the boiler to the heating and use it.

|

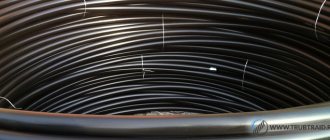

Advantages and disadvantages of polypropylene pipes

Metal pipes are used less and less in autonomous heating systems. Their place is taken by brothers made of polypropylene. They are easy to install and high temperature resistant. Pipes can be easily soldered and cut, and no less easily laid directly into walls or floors. In the event of a breakdown, it will take a minimum of time to replace the damaged area. If the installation is carried out from scratch, then when using polypropylene pipes, the terms of work are significantly reduced.

There are various sizes of PP pipes. The diameter is selected based on the power and size of your heating system.

What are the advantages of polypropylene pipes?

- Sufficient strength to work in autonomous systems - plastic pipes withstand pressure up to 10 atmospheres and higher, without bursting under its influence;

- Resistance to high temperatures - combined pipes made of plastic and aluminum are capable of operating at a coolant temperature of up to +95 degrees. A short-term excess of the maximum possible temperature is also allowed;

- Excellent passage of the coolant - the inner surface of the plastic pipes is very smooth, so nothing interferes with the flow of the coolant;

- No corrosion - if steel is afraid of rust, then plastic is not afraid of it. They do not deteriorate and do not rust, retaining their properties for many decades;

- Long service life - manufacturers assure that polypropylene pipes serve for 40-50 years and even more;

- Resistance to salts and aggressive components - polypropylene reacts calmly to the increased acidity of the coolant without collapsing or deteriorating;

- Ease of installation - the heating system can be easily assembled by yourself, without outside help.

The list of advantages is quite large, which is why polypropylene pipes are so widespread.

Unfortunately, polypropylene pipes also have disadvantages:

- The presence of heat loss - you will have to pay for this with additional heating costs... In some cases, the problem is solved with the help of additional thermal insulation applied on top;

- You need to learn the correct installation - those who are used to working with metal pipes will have to learn the principles of their installation from polypropylene.

Output

Each of the boilers presented by me has been repeatedly tested and is guaranteed to work, which one to choose is your business. The video in this article has a lot of recommendations, and also shows the subtleties of the process. If you have any ideas or have any questions, write in the comments, I will try to help.

A small homemade electric boiler can heat a medium-sized private house.