Old panel houses are especially in need of insulation. This becomes noticeable with the onset of cold weather, when the heating system does not cope with its tasks. To carry out such work today, there are many ways, for example, insulating the walls of a panel house from the inside. This technology is relevant if external thermal insulation is impossible due to the fact that the facade of the building is not allowed to be touched.

Features of cold wall insulation from the inside

It penetrates the cold outside through the seams in panel houses. If it is not possible to fill them in due to certain circumstances, the insulation should be carried out from the inside. For this, you can use expanded polystyrene or mineral wool. These materials are complemented with foil insulation or separately use insulation paint. Usually, the work involves the installation of a frame, inside which additional insulating layers are laid, overlapped with drywall from above.

If you intend to load the walls with something heavy, then you can apply plaster over the insulation, saving money. When there is no desire to install drywall, you can plaster both foam and mineral wool. In the latter case, the material must have a high density. If you want to prefer mineral wool for insulating a panel house from the inside, then it is better to choose its basalt variety, which is also called stone. This material is good because it is not afraid of moisture and tolerates heat well. At the same time, it is possible to exclude the use of a membrane, which, with external thermal insulation, plays the role of a steam and hydro barrier.

Permission for external and internal insulation of the facade of an apartment building

In the Russian Federation today there is no document regulating the processes of wall insulation in multi-storey buildings.

It is interesting that in this regard, different rules and recommendations are in force in certain regions and constituent entities of the Russian Federation. In some of them, there are whole programs for facade insulation of apartment buildings, which is carried out for money taken from the state budget. If your stalinka or other apartment building is not on the checklist for insulation, then in order to create it, you will have to contact the special services of the city. Typically, these are utilities and institutions. You should always take into account the fact that the insulation of the walls of an apartment building from the outside is usually carried out for at least a few days.

When insulating, it is important to follow the technology, otherwise it will be ineffective

What is the outer wall of any apartment building? That's right - this is the so-called common property. The last statement is true even if the whole house is in someone's private property and privatized. Insulation of any walls of the facade of a dwelling necessarily changes its appearance. That is why, before insulating the walls, you will need to first agree with the architect, as well as with the public utilities serving the house. It is easier to do this despite the complexity of the wording - it is enough to write an application to a specialized authority. Insulating the walls of an apartment building from the outside will be legal only if it is possible to obtain a positive decision and collect several signatures of the residents of the apartment building at once. It should also be noted that the complete insulation of the facade walls is much more effective than the mosaic. Refuse to insulate the facade walls, as you might guess, can also.Especially if the apartment building has historical value or the house is registered as an object of cultural heritage in the relevant registers. If we are talking about the capital, then it is simply impossible to achieve external insulation of the facade within one apartment.

Warming an apartment with special materials should only be done by professionals

Thermal insulation of the walls of an apartment building from the outside of the external type in the above-mentioned buildings is possible, therefore, only if it covers the entire dwelling. Interestingly, in other regions of the country, external insulation of dwellings is allowed only under such circumstances when all its residents will vote for. The situation is different with our neighbors in Ukraine. There, the facade walls of apartment buildings are the private property of residents living in the house. By law, all decisions related to changing the original appearance of the building must be carried out collectively and must be voted on at special meetings. In fact, in many Ukrainian cities, no one forbids insulating external walls - often no one asks their neighbors for permission, but such behavior may even end in a lawsuit. There were cases when, by a court decision and a meeting of all owners, illegal external insulation was simply removed.

Work starts from the very bottom, or from the middle

Insulation types

When the walls are insulated inside the apartment of a panel house, one of the many modern solutions can be used. In addition to the above options, it can be expanded polystyrene, which is much easier to work with. But it is important to take into account that the foam does not allow steam to pass through, which means that over time, dampness will form under it, which will cause the formation of fungus and mold.

If you do not want the walls of the apartment to move too far inward, you can choose warm plaster, but the effect from it will be much less than from foam materials. You can also choose modern liquid ceramics. Just 1 mm layer will be enough to equate it with 5 cm of mineral wool. Liquid ceramic consists of air-filled bubbles.

If a store offers you foil insulation, and the seller claims that it can be used as a stand-alone material, you can be sure that this is not the case. The effect of such a layer, of course, will be, but not as significant as they want to imagine.

Minvata

When insulating the walls of a panel house from the inside, you can use mineral wool. But experts advise using it in extreme cases, because it needs to be protected for at least two reasons. The first is that with free access of particles to the room, they can harm human health. The second is expressed in the fact that the mineral wool is saturated with moisture, settles and loses its original properties. Even if you close the insulation layer with a film on both sides, water will still penetrate into it, which over time will nullify all efforts to heat insulation. But if you still want to install it, then you will need to install the frame, and bring the end parts of the material into the profiles.

Insulation from expanded polystyrene

If you want to do the insulation yourself, you can use expanded polystyrene. It can be installed on glue, additionally reinforced with dowels. A fiberglass mesh is applied on top, which is embedded in the plaster. With such insulation of the walls of a panel house from the inside, it is necessary to additionally think over the ventilation system, since the created layer will have a low vapor permeability.

Before installing the insulation, you need to remove all old finishes from the walls, including wallpaper. Damage is repaired with putty. Further, the surface can be covered with soil. An acrylic-based composition is perfect. It is better if it has anti-fungal properties.Before installing the insulation, waterproofing should be laid on the wall. You can use plastic wrap for this. Insulation is installed on top, you need to start working from below, installing the plates in a checkerboard pattern.

As soon as the adhesive is completely dry, which will happen in about 2 days, holes can be made in the insulation, which should be 6 pieces per sheet. Dowels will be inserted there, which will further increase the strength of the structure. The end seams should be filled with pieces of insulation. At the next stage, a reinforced mesh is applied, which is recessed in a liquid finishing layer. Put putty on top, which is covered with wallpaper or other decorative material.

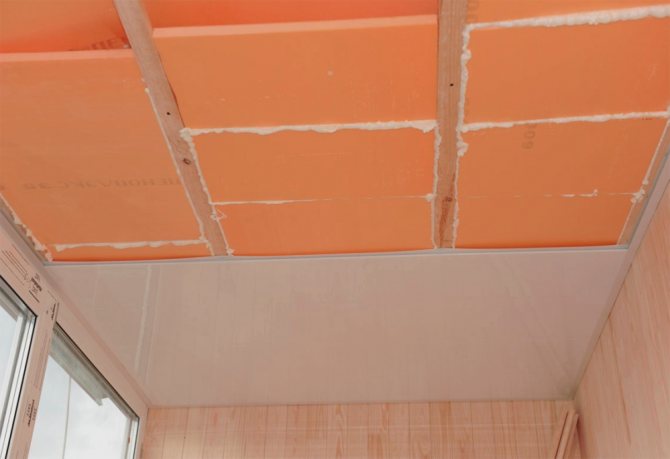

Extruded polystyrene foam

Insulation of the walls of a panel house from the inside is often carried out by an extruded type of expanded polystyrene. The work is carried out according to the same algorithm as described above. This material can be selected taking into account the density, which reaches 47 kg / m3. This indicator affects the strength of the material, but in a room it is not too important. The formed layer will be flammable, therefore it must be well protected from ignition. For more convenient installation, you should choose products with a groove on the edges. It provides a snug fit of the plates to each other.

Styrofoam use

When insulating the walls of a panel house from the inside, polystyrene is rarely used, since its effect on health has not been proven. If it is necessary to carry out work in the area of the ceiling, then it is better to mount from the attic side. When buying this material, it is important to exclude the artisanal method of production by requesting a certificate confirming the quality.

Application of keramoizol

If you want to insulate the walls with your own hands, you should consider liquid thermal insulation, which is made on the basis of polymer resins. Among the ingredients are mineral fillers, which are in the form of balls. They provide thermal energy reflection. When applied, the composition and balls are polymerized, which allows you to get an imitation of a thermos.

This material allows not only to insulate the walls, but also to make them more protected from the penetration of extraneous noise. This relatively new material is sold in containers of different sizes. It is characterized by the qualities of vapor and water resistance, as well as durability. Installation consists in the formation of several layers. To achieve the best effect, you need to apply 6 coats. The direction of movement of the brush should be perpendicular between sets. The only drawback of this solution is the high cost.

Insulation penoizol

Insulation of the walls of a panel house from the inside is sometimes carried out with penoizol. It is a liquid version of polystyrene, which is made directly on the construction site and poured into hollow structures or formwork. In this case, we are talking about carbamide foam, which is rather difficult to use in domestic conditions.

The work is inexpensive, the result is practical, and the manipulation time is reduced. Penoizol has a low density, is ready to serve for a long time and is characterized by insignificant thermal conductivity. The layer is not dangerous in the event of a fire, the material has the qualities of environmental friendliness and cannot create suitable conditions for the emergence of biological life.

Using astratek

For internal insulation of a panel house, astratek can be used, which is liquid thermal insulation. The structure of the material is microporous. With it, you can form a seamless coating that significantly reduces heat loss without creating additional loads on walls and floors.

With such insulation of a panel house from the inside, you can be sure that the material can be used under different temperature conditions, as well as on different objects. The material adheres well to the surface, excludes corrosion, and contains organic solvents among the ingredients.

External insulation

Carrying out work on insulation of the facade of a multi-storey building

Insulation of the facade of a panel house is carried out in the following stages:

Preparatory stage

Preparation of the facade surface is necessary - the end walls of the panel house are leveled, the plates are cleaned of plaque. It is also important to close up voids, cracks, and the joints of the panels are sealed. If necessary, it is worth laying a seal between the joints, while a special mastic is used to seal the cracks. The unevenness of the surface of the walls within two centimeters is allowed - such a deviation can not be repaired. When all materials are dry, the wall is impregnated with a multipurpose primer applied with a spray gun or roller.

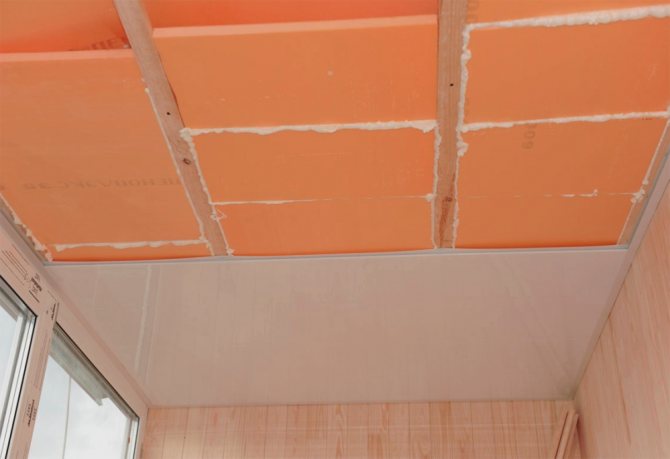

Insulation installation

Since in the overwhelming majority of cases, foam is used for thermal insulation of panel houses, it is worth considering the technology for installing this insulation. You can fix the foam using the following methods: put the plates on glue, fix with dowels, or connect these two options, this is the most reliable choice. The direction of pasting is from bottom to top. In this case, pasting begins with the installation of the starting plate.

After that, we begin to apply glue to the surface of the panel house - the technologies used directly depend on the quality of the walls. If they are even, you can apply the glue with a comb. If, as is often the case, the walls are uneven, then the glue is simply poured onto the surface. It is important to carefully fill the seams with glue. All this allows you to get rid of voids under the heat insulator. There is no need to apply glue to the foam.

Installation of foam on the wall

The option when the glue is applied to the foam, and not to the house, is not suitable in this case, since the voids under the insulation will become natural bridges of cold, which will reduce the effectiveness of the entire event as a whole.

Apply the foam to the glue layer and press it well. After gluing all the plates, you must leave them alone for a few days. During this period, the glue solution will dry out and shrink, after which it will be possible to perform the next stage of work. As for fixing the plates with dowels, you can choose plastic mushrooms. This is due to the lightness and low strength of the foam - such fasteners will save the facade from unnecessary heat loss.

It is worth paying attention to the gaps - they must be filled with polyurethane foam, cutting off the excess after the material has solidified.

As for the caps of the dowels, they must be covered with an adhesive mixture. All irregularities left after the glue dries can be removed with ordinary sandpaper.

Preparation for reinforcement

The fragility of the foam is a serious drawback, therefore, the insulation needs reinforcement - it is enough to glue a thin mesh. Such protection should prevent the destruction of the foam due to atmospheric phenomena and other adverse factors.

Preparation for reinforcement is as follows: first, the corners are pasted over, after which you can proceed to pasting the walls themselves. To simplify the process, meshes with ready-made corners are used, which minimizes the time required. If there are no such nets, then you will have to make corners from a regular mesh. It is enough to cut a long strip 30 centimeters wide and bend it at an angle - such a structure is pressed against the corner of the house greased with glue. In general, cutting the mesh into fragments greatly simplifies the installation itself, which allows you to consistently close the areas smeared with glue with fragments.In this case, at the junction, the mesh should be overlapped.

After gluing the mesh, it is necessary to wait for the glue to dry, after which it will remain to clean the excess solution with a plastic trowel and remove the irregularities.

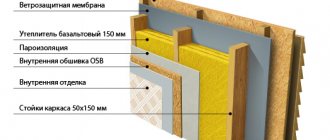

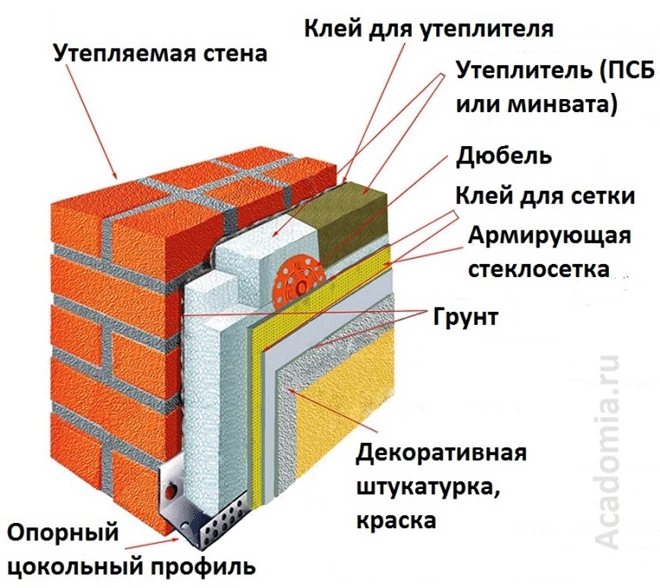

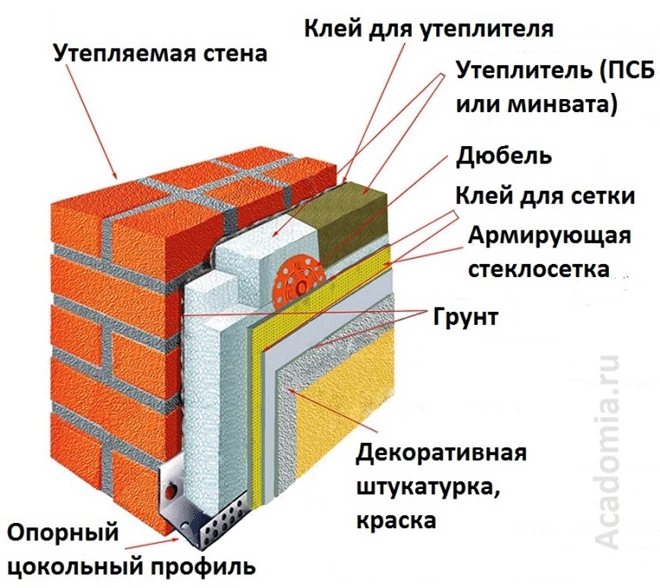

Insulation scheme for the facade of a panel house

Finishing

Before finishing, a leveling layer is applied to the entire treated facade. After that, you need to apply a primer and a layer of plaster. The final stage is painting the wall, preferably in a color that will not stand out strongly against the background of the main color of a multi-storey panel house.

Installation of insulation on brick walls

Before starting work, it is important to decide which material will act as a heater. For a start, it is important to weigh all the pros and cons and understand that condensation will form in case of internal insulation in any case. If you nevertheless decide to install polystyrene or any other material from the side of the room, then you must fix a vapor barrier film on the wall, which will go to the ceiling and floor. Seams are glued with tape, they must be laid with an overlap on top of each other.

Now you can install the lathing, the spacing between the elements of which should be less than the width of the used thermal insulation, if it is elastic. In depth, the frame must correspond to the thickness of the insulation. Thermal insulation plates are laid out in the cells, they are covered with vapor barrier on top of them, and the seams are sealed. The next layer will be a counter-lattice, which is sheathed with chipboard or any other sheet material. This work is necessary in order to ensure that the materials inside are as well ventilated as possible.

Who pays?

Payment is the second most important issue after authorization. The best option is to carry out the insulation at the expense of the management company. The most difficult option from the point of view of implementation is the insulation of all walls of the house at the expense of the residents. If in your region there is no fundamental prohibition on insulation, then we recommend holding a meeting, collecting the signatures of tenants and trying to resolve the issue of payment by attracting a council or a management company. If there are indications for insulation, then this scheme may turn out to be quite real.

golicin / Fotolia

Thermal insulation of walls using the electric floor method

If you decide to abandon the installation of extruded polystyrene foam, replacing this method with wall insulation using the electric floor method, then you must weigh all the positive and negative aspects of this technology. Experts say that good heat transfer cannot be obtained in this case. The heating components will be located in the wall, and the heat will have to make its way through the trim or drywall. In this case, the space will warm up only a few tens of centimeters from the wall, while the heated air will immediately rise upward. The result will be the need to install an additional electric heater, which will entail costs.

If wallpaper and tile decor are glued on the walls as a finishing finish, you may be faced with the fact that the materials will move away from the surface with constant heating. With such a heating arrangement, it will not be possible to put pieces of furniture or electrical equipment against the wall, since they will quickly fail, in addition, they will block the air flows.

Having installed such a heating system, you will encounter impressive heat losses, because the energy will go not only inside the room, but also outside the house. Foil insulation is placed under the infrared fabric (to exclude such phenomena), but this only aggravates the situation, and the heating even decreases. Such walls, where the electric cable is laid, will no longer be used for hanging equipment and furniture.The same condensation will form between the warm and cold surface of the wall, which cannot but become a serious obstacle to equipping such a heating system.

How is the insulation of multi-storey buildings carried out?

The sealing of interpanel seams and partial insulation of brickwork, which have been used in our country for many years, have long outlived their usefulness. All these measures do not guarantee that the house will not collapse further. The best option is complete insulation with facade finishing. This method finally solves the problem, since modern insulation lasts 50 years or longer.

There are 2 main methods of such insulation:

- Plaster or wet facade... When installing it on the wall, a layer of insulation is first applied, covering all voids and interpanel seams. After it dries, a reinforcing mesh is mounted on top, and then the finishing plaster is applied. This is a very reliable option, suitable for most houses, regardless of the type of walls, but its big drawback is its durability. Installation work takes a lot of time and can only be performed at positive temperatures;

- Ventilated or hinged facade... In this case, the insulation is applied to the metal frame, therefore there is a gap for ventilation between the insulation and the wall. If the installation is done correctly, moisture will not accumulate under the insulation, fungus or mold will not appear. A big plus of such insulation is the ability to choose the appearance of the house. Residents can choose the finishing materials of the desired color and texture themselves. Installation of the plaster facade does not take long, taking three to five days.