Features of production

Modern companies in most cases use technologies that first appeared in Germany. For the first time such solutions were developed more than 20 years ago. Clinker panels have always been considered a good insulation, they were suitable for the restoration of buildings, public or just with dilapidated facades.

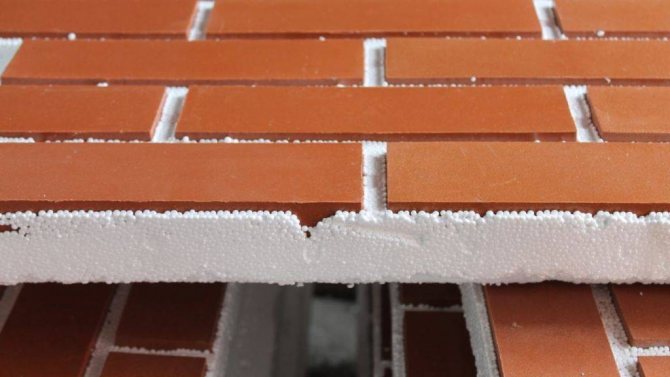

Expanded polystyrene PSB-s - 35 is considered the basis for such products. This high-density material is also called self-extinguishing. The thickness of one sheet can reach 50-80 millimeters.

The base and the tile are connected to each other by pressing. Polyurethane glue is also involved in this process. The total operating time of the material is up to 30 years, but with proper care it can last much longer.

Panels have two main functions:

- Warming.

- Decorative.

Indoors with finishing from such panels maintain a high level of temperature. For some time, the indicator remains the same.

Metal panels

They are a composite material consisting of metal surfaces and a polymer layer. Aluminum sheets are available in both square and rectangular shapes, which allows you to cut the required dimensions. When installing the panels, special brackets are used. The tightness of the connection is achieved using the groove system. The main advantages of the application are:

- light weight;

- insignificant thickness;

- reliable protection of walls from all kinds of damage;

- due to the composite material, the material has a high degree of noise protection.

With proper installation, the panels can be used not only for private households, but also for high-rise buildings.

Metal panels

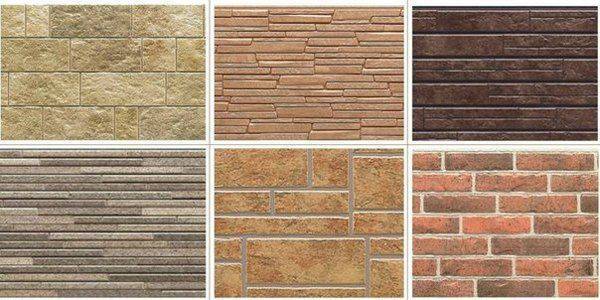

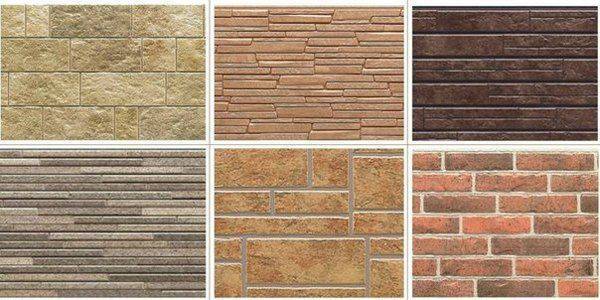

Types of panels for imitation and design

The products have both smooth and embossed surfaces. The latter are able to imitate stone, wood or brick. Thanks to the development of technology, such heaters are as similar as possible to the original. At the end of the finishing work, the house looks like it really was built of stone or wood.

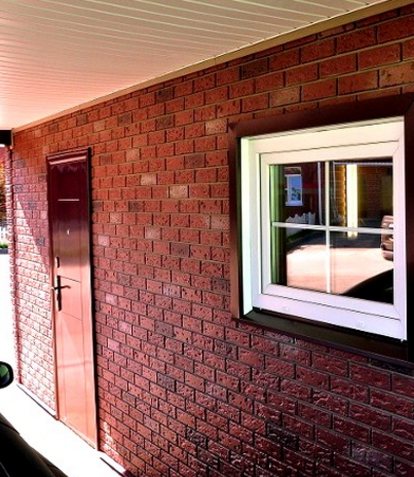

Under the brick

Insulation of facades with brick panels is a popular solution. It is versatile and fits most architectural styles. Imitation is achieved thanks to vinyl, a more practical material that can retain its original appearance for a long time. Manufacturing companies offer their options for imitation brick, which are different not only in texture, but also in color. The surface of the slab may even be rough or uneven, which will further resemble the original.

Under the stone

It is a material that makes the appearance of the house more "noble". Since finishing with natural stone is an expensive pleasure, it is associated with wealth. Vinyl panels that imitate masonry are cheaper, but even visually, it is sometimes difficult to distinguish them from the original. And it is easier to care for such walls - just wipe it with a sponge soaked in detergent. Products imitating stone do not lose their properties at the following temperature ranges: from -50 to +50 degrees Celsius.

Not all houses can be faced with real stone. But vinyl imitation can be installed over concrete, wood or brick structures.

Under the tree

Natural wood is considered a noble material that makes the home more comfortable and atmospheric. However, it has an important disadvantage - low resistance to moisture. And this is despite the fact that microorganisms are so fond of the tree, which strive to make their holes in it.Fiber cement facade panels with wood imitation do not have such disadvantages.

The color and structure of the material is preserved for many years. The appearance is selected based on the wishes of the customer: painted or natural wood. In addition, fiber cement in terms of environmental friendliness outperforms PVC, and imitation wood imitation evokes "cozy" associations.

We are approaching the finish line

The last two stages of installing facade tiles with insulation is grouting. A trowel layer is applied to the entire surface and rubbed over the entire surface with a brush. It is necessary to carry out the jointing no less than a day after the shrinkage on the glue (do not forget that fastening with dowels is still between these two stages). After grouting, thoroughly wash the surface with a sponge. Grouting and washing them is not quick, but what to do is one of the downsides.

Let's summarize the summary of our review and a small instruction for the installation of panels for facade insulation.

PROS:

- Ease of installation, no wet processes;

- Attractive appearance, imitating brick or stone;

- Good thermal insulation.

MINUSES:

- Higher cost, before, say, "Bark beetle" plaster;

- The need for thorough grouting, followed by washing the solution.

If you like to experiment, why not use warm facade panels? But, it will be a rather long experiment. Wikipedia says that panels last from 50 to 100 years. So, perhaps our grandchildren will be able to find out about the results.

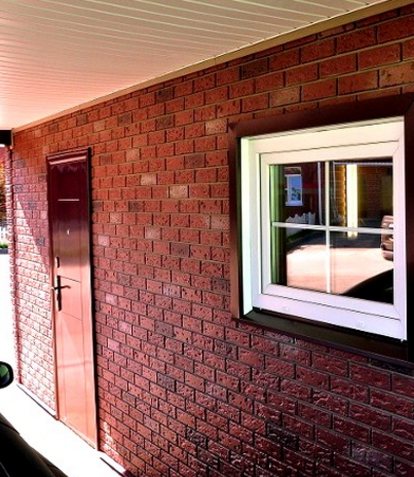

Brick-like facade panels

Brick buildings are traditionally reliable and aesthetic structures. They talk about a decent material level of residents, and about good taste.

But building a brick building has never been cheap. Brick itself is an expensive material, and the work of bricklayers is also expensive.

Brick facade panels give the building the same look as a fully brick one. But the price, for example, of a brick-faced panel house, is several times cheaper.

But the external difference between a brick building and a building lined with brick wall panels can be seen only up close or even just felt by touch.

Panels for exterior brick wall decoration are made in monolithic and combined structural design.

Combined panels consist of two layers - external plastic and internal polystyrene.

Fastening the facade panels under the brick is necessary for the adhesive composition. If hot glue joints are used, then they are practically inseparable, long-lasting.

The panels can be used both to cover the walls completely, and to decorate only the basement floors or levels of the building.

To give the plinth a natural projection on the wall below, a special lathing is made from metal profiles or from wooden beams.

What kind of sandwich and how is it eaten?

Facade panels for exterior decoration of the house are essentially a "sandwich", which consists of two or three layers:

- Decorative facing layer;

- Insulation;

- Internal base.

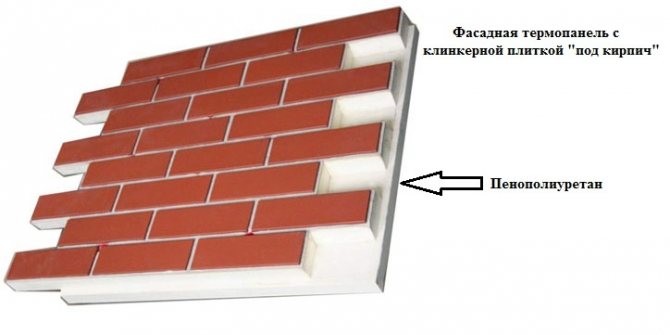

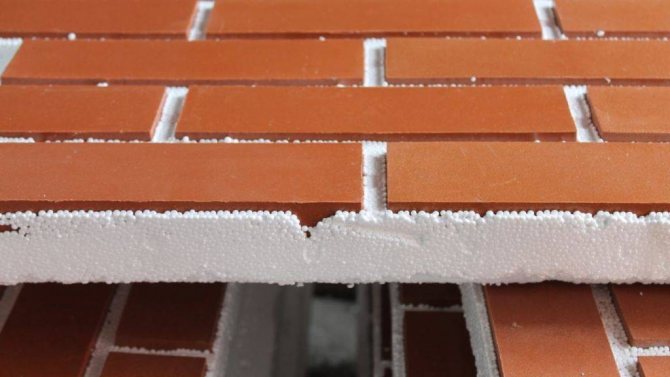

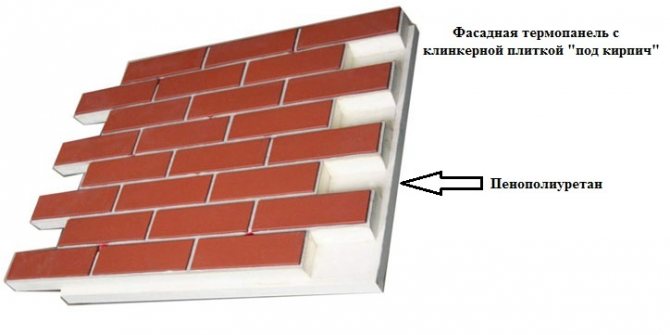

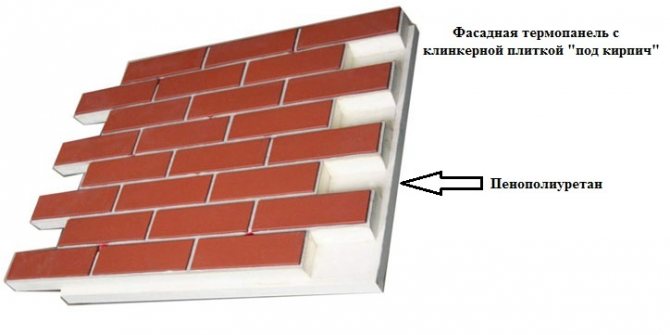

Most often in the domestic market there are clinker panels for the facade. This type of insulation systems is a layer of expanded polystyrene or polyurethane foam into which clinker tiles are recessed during the production process. Clinker is a durable clay material that is manufactured at temperatures over 1000 degrees Celsius.

For the sake of fairness, it should be said that there are also panels covered with metal and decorative plaster. Why was this type of insulation called a semi-finished product a little higher? For example, because a person himself can cover the wall with foam and stick clinker tiles on it. However, this approach will take much more time, and, as a result, will differ greatly in aesthetic properties.

Facade panels for brick by foaming polystyrene foam or polyurethane foam (polyurethane foam), and then under pressure, as it were, soldered into the mass of clinker tiles. The result is a durable façade element. To tear off the tiles, you need to apply a force of 300 kg. It will be very difficult with your hands. Although, for the sake of fairness, it should be said that even a damaged panel element can be easily restored using polyurethane foam.

We offer you to familiarize yourself with What are the PVC panels for the bathroom

You need to buy a suitable clinker tile (or use the one that has disappeared and apply a small layer of foam to the tile and to the place where it should be glued. Then carefully attach the tile to its original position. Below we will discuss three disadvantages of thermal panels. But, since one of them is related to installation, this issue will be discussed in the corresponding section.

Facade panels for home

Facade structures for a house are separate elements that are attached to a frame made of metal or wood. There are parts that are attached with glue and do not provide ventilation gaps between the wall and the cladding.

IMPORTANT! The panels are fastened together with special fasteners in such a way that no gaps are formed between the cladding elements for moisture, debris and dust to enter.

The decorativeness of facade structures lies in the fact that the material imitates wood logs, boards, brickwork, natural or artificial stone.

Wall cladding does not provide for additional leveling or preparation of the walls of the house. In addition to a variety of textures, facade slabs can be made of various materials (metal, ceramics, PVC, wood), and their installation can be carried out vertically or horizontally.

The assortment of sheets assumes not only a variety of textured patterns and design, but is also presented in a variety of colors.

The most important element of interior design

Fiber cement, thermal insulation, three-dimensional - the range of these materials is constantly expanding, and the price is steadily decreasing

- help to significantly speed up the entire process of wall decoration - some panels have an area of 2-3 square meters, which is closed in one fell swoop;

- get rid of the careful time-consuming finishing of the rough surface of the wall;

- provide additional opportunities for hydro and thermal insulation;

- have such a large number of varieties and design proposals that you can always pick up, and far from "something", for any design of the floor, walls, for any furniture and fittings.

Glass panels are also used, and not only in kitchens.

Classification

A large number of proposals forces, first of all, to classify the submitted material.

In appearance, but we can say a little differently - in terms of the ratio of length to width - they are divided into:

- rack - here the most famous representative is a long-standing wooden lining, its promoted “fellow-analogue” with a rounded profile - finishing “block house” and all kinds of newfangled plastic analogs; another thing is that the installation can now be carried out not only horizontally, but also vertically, and the width of the panels can vary from edge to edge from 10-20 cm to 40-50, and this is with a length of 2 to 6 meters; we will refer to this class and three-dimensional options from fiber cement and laminate;

- tiled - we can say that this is a tile, but in a plastic version and much larger than the one that you chose for finishing the bathroom; here the size 50 by 50, perhaps, will be the minimum; options 80 by 80 or 90 by 100 are not uncommon - in any case, this species tries to be as close to the "square" as possible; the main advantage of the tile remains here as well - the creativity of the independent invention of the drawing on the wall remains available to you;

- sheet - such panels have the largest dimensions, 2 by 3 meters, meter by two; such dimensions force us to look for other methods of fastening - ordinary light clamps are rarely used here, nails and special glue are already in use.

According to the material, the panels can be:

- wooden - a large class, which includes both natural wood and particle boards and fiber boards (chipboard and fiberboard); you will definitely decorate the walls of a house outside the city, in nature, with a truly natural material, to which, however, it is necessary to present increased requirements for drying and processing; this applies primarily to the lining and block house, and the processing is also required to be environmentally flawless;

- plastic - a material that has found a place for itself in almost all areas of construction, due to its unpretentiousness, great variety and relatively low price of competitors;

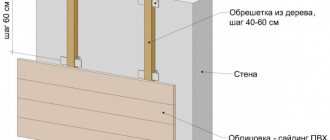

Such a do-it-yourself installation on a crate is one of the simplest and most commonly used

- glass - not yet fully appreciated material that can often be seen in kitchens, but it boldly invades other rooms, maybe not as an independent, main component of the interior, but as a very good addition and highlight;

- metal - aluminum dominates here; perhaps it is metal as an interior decoration that causes distrust, but the fact is that the vast majority of amazing three-dimensional panels are based on metal, and this radically changes the attitude towards this type.

Helpful advice! We advise you to bear in mind that gypsum and leather panels can also be found on the market. The first ones use the possibilities of the material to take any kind and color at the request of the designer, hence their undoubted plus. And the latter can support the corresponding interior well.

In the photo, working with clapboard - everything is simple, but careful preparation and skill are required

Read also: Chrysanthemum in a pot from a care store

Advantages and disadvantages

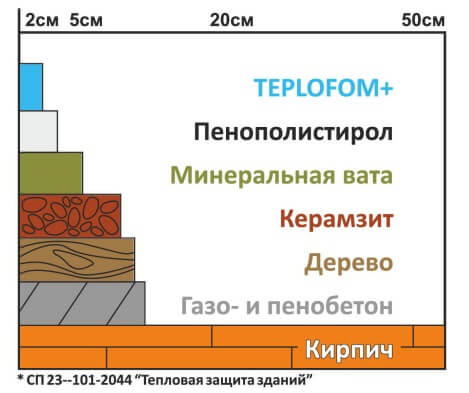

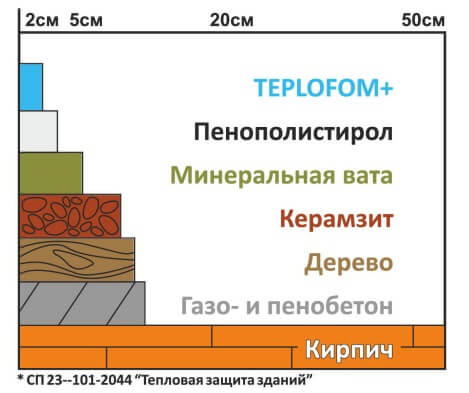

The main advantage of the thermal panels used to decorate the facade of the house is the effective thermal insulation of the building - 50 cm of polyurethane foam replaces 1 meter thick brickwork. At the same time, even after several years of operation, when the plastered surfaces already change color and crumble, the heat panels retain their color, strength, and thermal characteristics. This material does not require any special cleaning or special care. Withstanding any weather conditions and mechanical stress, it will last at least 30 years.

It is easier to install heat panels than other materials used to decorate a house from the outside. For this, they are equipped with special fasteners to minimize the possibility of damage to the thermal panels during installation. The process of wall insulation in this way can be called an investment in the future, when subsequent savings are created both on repairs and on heating with a minimum investment of time and money.

The owner of a private house, for sure, will suit such an advantage of the material as an aesthetic appearance. Moreover, the wide assortment of the modern market allows you to choose panels, the surface of which imitates both brick and natural stones. Materials are also available in various colors. As a result, the decoration of the facade also increases the uniqueness of the building.

Cladding panels with insulation have few disadvantages:

- the ability to install only on perfectly smooth enclosing structures. Even a slight unevenness can lead to a distortion of the panel and a decrease in its heat-shielding properties;

- the increased cost of both the thermal insulation itself and its installation compared to other materials. Basically, these are approximately the same amounts - you should not save on installation, since if it is carried out poorly, the junction of individual elements can disperse in just a few years;

- the formation of condensation under the panels, unless a small gap (at least 4 cm) is left between them and the walls of the house. It is also worth considering the vapor transmission coefficient (the ratio of thickness to vapor permeability) of the enclosing structures, which should be higher than the same indicator of the insulation.

Clinker panels

Clinker tiles are the most common decorative part with insulation among panels. Due to the variety of colors and imitations, it will fit into any home furnishings interior, it can be:

Manufacturing technology

The name of the tile is due to the main external element of the decor - clinker - clay tiles, with a complex manufacturing technology by firing at a temperature more than a thousand degrees. Then these heavy-duty slabs are completely embedded in polystyrene foam or polyurethane foam using a special technique. Experts have proven that tearing off such a tile almost impossible, for this you need a jackhammer and a force of more than three hundred kilograms. Tile tearing is extremely rare, and then this defect can be easily eliminated using polyurethane foam.

Read also: How to grow a flower female happiness

Structure

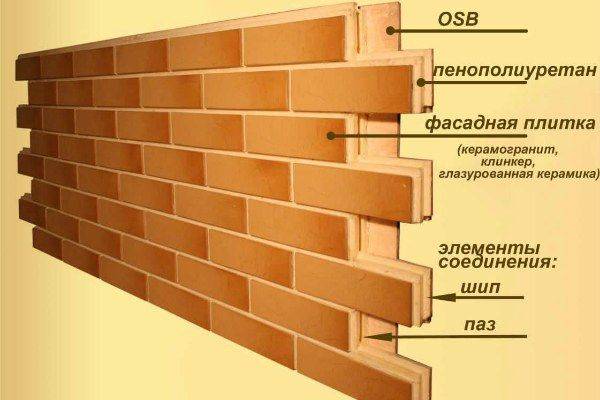

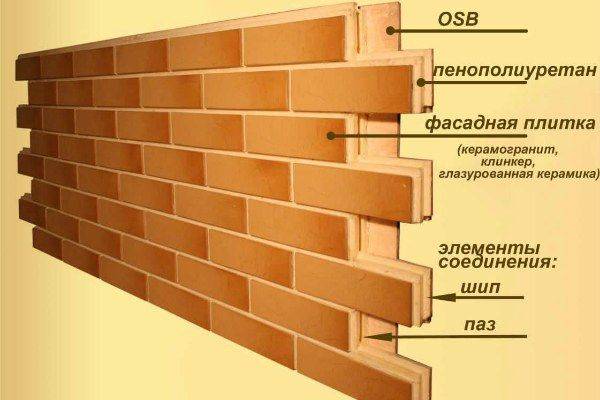

More often, the main insulation in such plates is OSB - a multilayer material made of shavings and chips, this provides not only strength, but also additional rigidity to the insulation. Also act as a basis:

Owners like this type of cladding also because the facade in the future It does not require special care - the appearance is always like new and just produced. In addition, this type of panel reliably protects the walls of the house from destruction and environmental influences.

As for the color, experts recommend placing blocks with darker shades of clinker tiles and with a larger pattern under the basement. This will give the building a special style and solidity.

Installation features

All types of facade panels can be installed on even and smooth surfaces without preliminary preparation.

In cases where the walls have irregularities due to the properties of the material (logs, brickwork) or defects associated with long-term operation without repair, the installation of a leveling frame is required.

The material for it can be wooden slats, bars or a galvanized metal profile.

The step of the lathing corresponds to the size of the panels. Their mounting holes should be in the middle of the bar. The profile creates an absolutely flat vertical plane so that the facing parts are fastened without distortion and kinks.

The presence of the frame provides a gap between the main wall and the facing layer, which improves ventilation and removes excess moisture.

Installation is carried out from the bottom up and from the corners to the center. If there are special corner pieces, they are installed first.

Some types of thermal panels provide for the ability to cut and fit the material directly on site.

The corner connection of such parts is formed by filing their ends at an angle of 45 °. The joint is then closed with a corner strip or rubbed in dry weather with special compounds at the stage of sealing the seams at the end of installation.

Most decorative items for outdoor use have hidden fastening. Insulated wall panels for exterior decoration are attached to wooden surfaces and metal profiles with self-tapping screws.

For concrete and brick bases, dowel-nails will be required. The length of the fasteners is selected based on the thickness of the insulating layer, taking into account the required depth of entry into the wall.

It is recommended, if possible, to mount each subsequent row of thermal panels for the facade with a horizontal offset from the previous one, so that the vertical seams do not coincide.

To do this, use additional parts or divide the whole in half.Thermal panels for the facade are cut with a grinder with a corresponding disc, and the polymer insulation layer is cut with a knife.

Correct installation of insulated facade panels will result in a beautiful exterior finish for a dry and warm house. All work will be completed quickly and with significant cost savings.

You may be interested in reading about basement panels and panels for brick (stone).

Have you chosen? Are we mounting?

The insulated facade panels sit on the glue mixture or guides. But, before that, it is imperative to wipe the side edges of the panel with a brush. This is for better grip. If you have chosen an adhesive mixture, apply it to the back side of the panel, making it so that one thin layer covers the entire panel, as well as in several places - in the corners and in accordance with the facade relief.

We suggest that you familiarize yourself with: How to insulate a house from a cinder block from the outside - video, instructions

You need to start installation from the corner of the bottom row, and it is worth making a reservation that there are special corner panels. Carefully level them before applying the glue mixture - estimate, and only then mount them more thoroughly on the glue.

A day after shrinkage on the glue, panels with insulation are attached with umbrella dowels into the pre-drilled holes between the seams.

Pros and cons of using thermal panels for a wooden house

Finishing the facade of a wooden house with thermal panels has certain advantages and disadvantages. The pluses include:

- Installation comfort. The panels are lightweight and have a large area, which means that work is done faster. The material is easily lifted up and cut. The panels have locking joints, which ensure easy joints and strength.

- The panels provide high-quality insulation of facades. Their use makes it possible to protect walls from freezing. It is possible to speak about the effectiveness of such insulation by comparing the type of insulation used.

- They differ in moisture resistance. But water is still able to penetrate under the finish, during installation work of inadequate quality.

- Low weight of panels. As a result, the walls of the building do not experience a strong additional load.

- The decorative part of the material will not react to moisture. In fact, it does not absorb it, there is no destruction under the influence of ultraviolet rays, which will make it possible to maintain its original appearance for a long time.

- Easy care of thermal panels. There is no need for periodic processing and cleaning.

- A significant range of thermal panels. It is possible to choose options that imitate brick, stone or log masonry.

Cons of such products:

- Overpriced thermal panels. In comparison with competitors, the difference in cost is 3 times. Therefore, it is advisable to make the walls thick with high quality cladding.

- Duration of operation of thermal panels. The manufacturer indicates 50 years, which is possible with extremely careful use. It should be borne in mind that such terms are marketers' forecasts. The products appeared on the market about 10 years ago, therefore, it was not possible to verify this judgment.

- For installation, you will need even walls or a frame brought out to the level.

Advantages of insulated facade panels

Choosing insulated facade panels, you get several advantages:

- The load on the foundation will be small, because the thermal panels are lightweight (10 times less than the brickwork of the same area). You do not have to worry about the reliability of the foundation and the strength of the walls.

- Installation can be carried out all year round - there are no restrictions.

- The palette of colors and variability of textures will please even the discerning homeowner.

- In winter, the figures in the calculations of housing and communal services will be up to 40% lower. This means that after wintering a few winters, you will recoup the cost of the cladding.

- The fastening of the panels to each other is so strong that slanting rain is not terrible for the facade.

- The panels do not burn, do not support the growth of mold and mildew.

- The service life of such panels is at least 50 years, and if ABC-Klinkergruppe products are selected, the panel warranty will be 100 years.

Installation

The external walls must be leveled before installation. If they are even, then small errors will help level the plywood or similar materials. Further, on the facade, the most convex point is determined and lighthouses are planted along it on the foam. This is a labor-intensive work, which will be simplified by the construction of the crate. The frame system will not only save time, but will also help in creating a ventilation gap that promotes moisture removal.

The installation technology has its own nuances depending on the design of the insulated plates, but in general its scheme looks like this:

- A line is outlined along the perimeter of the house, which will be the starting mark for facing;

- When starting the installation work above the level of the plinth, you must first install the plinth profile on which the panels will rest;

- A wooden crate is attached to the wall, pretreated from fungus and mold. The step of the lathing should correspond to the size of the panels.

Figure 5. An important point

- Installation of thermal panels is carried out from the corner of the building from bottom to top. The ends of the facade elements are either filed and joined to each other at an angle of 45 degrees, or they are formed with a corner. In the second option, you need to start fastening with a corner element.

Features of the design of panels with insulation

Common to all types of thermal panels is the presence of at least two layers: an external decorative coating and an internal heat-insulating layer. The decorative coating performs the same functions as the classic facade panels: protection against mechanical damage and against the effects of wind and moisture, giving the walls a complete look.

IMPORTANT! There are three-layer versions of products called sandwich panels. In them, the heat-insulating material is located between two cladding layers made of metal .. For operation in conditions of increased fire hazard, four-layer thermal panels are produced in which a refractory material is located between the outer tile and the insulation

For operation in conditions of increased fire hazard, four-layer thermal panels are produced, in which there is a refractory material between the outer tile and the insulation.

The main stages of the production of insulated products with a decorative coating: preparation of block molds, foaming and drying of insulation granules, laying a decorative layer in a block mold, adding granules, heating the structure with hot steam (it is necessary for the granules to expand and form a layer of insulation), cooling panels.

The main purpose of using warm panels is to save on heating the building, which makes it possible to recoup the costs of their purchase and installation in the shortest possible time, provided that the house is located in a region with relatively cold winters. They are more expensive than conventional panels, but in most cases even more money will have to be spent on the separate purchase of siding and insulation (and their installation).

Products can be installed on most plastered and unplastered surfaces, including block and wooden walls, unfired brick, expanded clay concrete.

NOTE! Thermal panels not only retain heat inside the building during the cold season, but also prevent it from heating up in summer.

Decorative finishes are made from the following materials:

- Clinker.

- Porcelain stoneware.

- Aluminum.

- Cink Steel.

- Compressed wood chips.

- Pressed marble chips.

The main insulation materials are polyurethane foam, mineral wool, expanded polystyrene foam. The average density of this layer is 40 kg3 / m, thermal conductivity - 0.020 W / m * C, thickness - 6 centimeters or more.

The high density of the material not only makes it possible to better retain heat, but also increases its resistance to mechanical damage. The working temperature range is in the range - 170 / +170 C. Despite the high refractoriness, the possibility of ignition of the insulation is not completely excluded.

The weight of the panels varies within 10-25 kilograms. The estimated service life depends on the climatic conditions of the region, as a rule, it is 10-30 years.

Types of thermal panels

Facade panels with insulation for outdoor decoration are seamless one-piece blocks that are attached directly to the facade of the building. Such thermal panels most often consist of two layers: a decorative layer and a layer of heat-insulating material. The average thickness of such products is 6-12 cm. They can be made on the basis of:

- polyurethane foam (PPU);

- foamed polystyrene foam;

- mineral wool.

Products of improved design can also have a third rigid bottom layer, groove-spikes, built-in fasteners (metal insert plates), plastic bushings for drilling fasteners, etc.

The decorative layer of such panels can be made from:

- facade tiles (brick finish) made of clinker, porcelain stoneware or glazed ceramics;

- compressed marble chips to imitate stone or marble;

- glued-pressed wood chips;

- aluminum or corrugated board.

Granite Slab Finish Panel

Sometimes marble chips are also used in clinker products for a more realistic grout.

For finishing the corners of the house, angular curly elements are produced that imitate the texture of a stone or brick, which are matched to the color of the main wall or, on the contrary, contrast with the general background.

Metal sandwich panels are, in fact, a kind of "cake", in the center of which there is a heater, protected on both sides by colored aluminum sheets or corrugated board. The corrugated board has a protective film on top, under which there can be a pattern imitating natural natural materials - wood, stone, brick, etc.

Manufacturers

Both domestic and foreign companies are represented on the market. German manufacturers specialize in the production of high quality and expensive clinker tiles.

These include:

- TM A. D. W. - Klinker.

- TM Stroeher.

- TM Ammonit Keramik.

The prices of their products start at 1,800 rubles per square meter of tiles.

Russian companies also produce clinker tiles; you can find other finishes there.

- "Workshop of facade materials". Produces tiles imitating natural stone, brick and German clinker. Polystyrene foam with a layer thickness of 50 mm is used as a heater. The average price of products is 1500-1800 rubles.

- FTP-Europa. Manufactures clinker and ceramic granite thermal panels. Insulation materials used - expanded polystyrene and polyurethane foam 60 or 80 mm thick. Product prices are in the range of 1100 - 3600 rubles.

- Forska. Specializes in the production of budget options with a price of 1000 rubles. for 1 sq. m. Uses a ready-made decorative finish, purchased from Western companies, and connects it with insulation made of expanded polystyrene or polyurethane foam.

- "Ermak". It specializes in thermal panels of the middle price category (1800 - 3000 rubles) based on expanded polystyrene (40 mm thick) and clinker tiles.

How to make a panel yourself?

To try to make the panel yourself, you will need special equipment - machines are akin to those on which foam is produced (by foaming polystyrene granules). In addition, it is necessary to create a material from which it will be possible to make thermal panels. Thus, in the handicraft shop, two directions should be carried out at once: the production of foam and clinker tiles.

Tools Needed for Foam Production:

- dispenser for raw materials;

- special pump;

- forms;

- vacuum unit;

- steam generator;

- pre-foaming unit.

For the production of clinker tiles you need:

- kiln for roasting;

- Press form.

Expensive units are capable of producing more than 300 parts in one day. Handicraft equipment will be less productive and will be able to produce up to 100 elements.

As already mentioned, for the manufacture of thermal facade panels, polyurethane foam or foam is used. And this means, if clinker tiles are glued to the foam sheets, then, in fact, thermal panels are obtained. Although, this work is laborious, and it is unlikely that it will pay off. In addition, there is an offer on sale called "Combeterm". This is a polystyrene foam sheet with clinker tiles already glued on. Such a solution will be cheaper than a panel with PU foam filling.

The main types of insulated panels

Façade panels made of foamed polyurethane with clinker tiles glued to the outer surface are very popular.

They are distinguished by a wide variety of designs, imitating bricks, ceramics, various types of natural stone and even wood. The panels are installed meshing one over the other.

The high quality workmanship of the parts makes the joints almost invisible. Bushings made of plastic or metal are pressed into polyurethane to strengthen the material at the point of attachment to the wall.

Sometimes an inner core layer of OSB is added. The choice of panel thickness depends on the weather conditions. In a zone of a temperate climate, insulated wall panels with an insulation thickness of 60-80 mm are used.

Thermal facade panels with an outer layer of porcelain stoneware have excellent consumer qualities. They usually mimic masonry, giving the building an imposing appearance.

Their protective properties in relation to all types of mechanical, chemical and thermal effects surpass everything that other types of finishing materials can show.

Insulated facade panels made of expanded polystyrene with decorative plaster, including marble chips of various colors or fine-grained fractions of other types of stone, give a smooth, seamless surface during installation.

They are easy to cut and fit, install quickly, have a beautiful look and a low price. They are equally well suited for cladding office buildings and detached houses.

Large-area facades with a minimum of architectural elements can be quickly and efficiently insulated using sandwich panels.

They are three-layer thermoplates of a large area of two sheets of corrugated board with a layer of mineral wool, polyurethane foam or expanded polystyrene placed between them.

The metal is galvanized and has additional protection in the form of colored polymer spraying. The design of the panels and the method of their fastening excludes the ingress of moisture on the insulation.

SIP panels used in frame construction are arranged according to the same principle. But their outer layer consists of oriented strand boards, which, in addition to high strength, also have heat-shielding properties.

The main insulation is glued between two sheets of OSB. A wall arranged in this way needs additional decorative finishing.

Installation of thermal panels on a wooden house

Like many modern building materials, panels are installed using various methods - using a frame and on a wall. The second option will be the best installation technique for such material. However, it is not possible in all cases - for example, when the walls have a significant deviation from the level, it is optimal to mount the frame.

- Installation without frame. It can be carried out only if there is a flat surface of the walls. The meaning of this installation method assumes that the thermal panel is nailed to the brick wall by means of dowels through the holes made by the developer.

- Installation with a frame. It is carried out in almost the same way, however, the panels are screwed or nailed to the supporting beams. The difference is insignificant, except for the possibility of leveling the surface of the walls, the frame does nothing.It is possible to say that with the type of installation in question, the frame is harmful. Air circulates in the space between the panel and the wall, takes heat from the dwelling - this is why, after fixing 1 row, this cavity is sealed with a construction foam.

The rest of the finishing work is carried out in the same way as with other building materials.

Thermal panels have a tongue-and-groove edge where the bare insulation substrate is visible. In such areas, mechanical fixation is performed with dowels. In addition, the panels are fixed with EEPS glue used during the arrangement of the wet facade. The glue must be prepared in accordance with the instructions, mixing the mixture with the required volume of water. Installation of thermal panels on a wooden house:

- The product is tried on dry and the holes are prepared in the place of fixing the dowels.

- The thermal panel is removed and glue is applied to the ends of the insulation, keeping the thickness of 2–2.5 cm.

- Special glue is applied in large lumps to the inside of the tiles, which protrude from the grooved edge.

- Glue is applied in a continuous layer to the main part and rubbed in one direction with a comb with a tooth pitch of 1–1.5 cm.

- The panel is applied to the installation site and the mechanical fasteners are attached.

- Strongly, but evenly, the thermal panel is pressed directly against the wall. It is necessary to ensure that the glue protrudes along the contour of the insulation substrate.

- By applying a long rule, the product is aligned in relation to the adjacent elements and the control cord.

- The thermal panel is tapped with the help of a wooden block: in a place where a muffled booming sound is heard, the glue did not properly adhere to the base of the wall. Therefore, the product in question needs to be pressed down a little more tightly.

- Spacer nails are hammered into the dowels.

- The excess amount of glue is removed and the installation of the next panel begins.

When the glue is completely dry (sometimes it takes 35–40 hours), the tile joints are overwritten. For such purposes, a basic facade plaster is used, which is painted in the required color by mixing in dispersed pigment. The plaster is hydrophobic, effectively protects the substrate of thermal panels from water penetration.

Grouting is carried out as follows: initially, the material is introduced into the seam, using a tight bag with a cut corner, and then the remnants are pressed tightly and removed with a knife to join the brickwork. After a few hours after grouting, the finish is thoroughly washed with soap and water and a brush, preventing future efflorescence.

Features of using building panels

- Reducing construction costs

... The weight of one panel of insulation 50 mm thick is 4 kg / m². The material combines heat, moisture, hydro and sound insulation qualities. Building panels are assembled without auxiliary equipment. These factors can reduce the weight of the building structure, reduce the consumption of other materials and the cost of the object. - Simplification of construction, renovation and finishing works

... Soundproofing panels do not require plastering. Their flat surface is ready for finishing, including mosaics and tiles. Installation of TEPLOFOM + panels during the construction of partitions and walls is carried out without the construction of frame elements. The device of "warm floor" is made without screed, rough flooring, additional insulation and leveling building material. - The ability to implement complex design solutions

... Heat-insulating panels allow you to carry out projects of any complexity in interior design in rooms with high humidity (spa rooms, showers, bathrooms, etc.) and other rooms.

You can get more detailed information about insulation based on extruded polystyrene foam through the feedback form, by phone or e-mail.

| Panel | The size | Weight | |

| one-sided coating | double-sided coating | ||

| TEPLOFOM, 10 mm | 2500 × 600 mm | 2,98 | 5,48 |

| TEPLOFOM, 12.5 mm | 2500 × 600 mm | 3,1 | 5,6 |

| TEPLOFOM, 20 mm | 2500 × 600 mm | 3,46 | 5,96 |

| TEPLOFOM, 30 mm | 2500 × 600 mm | 3,94 | 6,44 |

| TEPLOFOM, 40 mm | 2500 × 600 mm | 4,42 | 6,92 |

| TEPLOFOM, 50 mm | 2500 × 600 mm | 4,9 | 7,4 |

| TEPLOFOM, 60 mm | 2500 × 600 mm | 5,38 | 7,88 |

| TEPLOFOM, 80 mm | 2501 × 600 mm | 6,34 | 8,84 |

| TEPLOFOM, 100 mm | 2502 × 600 mm | 7,3 | 9,8 |

Dimensions and construction of thermal panels

Exterior decoration of a house made of wood with front thermal panels is carried out using 3 types of them: ordinary, additional and corner. They have a total size of 70 by 114.5, 70 by 64.5 and 70 by 24.5 and 70 by 26.5 (cm). Regarding the construction, 2 types are known: 2-layer and 3-layer.

Double layer panels

2-layer thermal panels are considered the most affordable type of such material. The basis will be extruded polystyrene foam, on top of which decorative components are glued. The rigidity of the structure itself will be directly imparted by the insulation.

The service life will be approximately 15 years (provided that there is no influence of external factors). The material is not resistant to an aggressive environment, as a result of which there is a possibility of deformation.

Three-layer panels

3-layer panels have many advantages. The basis is an OSB panel, which greatly increases the reliability of the material. In the middle there is a polyurethane foam layer, which has sufficient strength and density. There are locks along the perimeter of the thermal panel, which make it possible to prevent the occurrence of cold bridges. The insulation performance of such products is higher than that of 2-layer products.