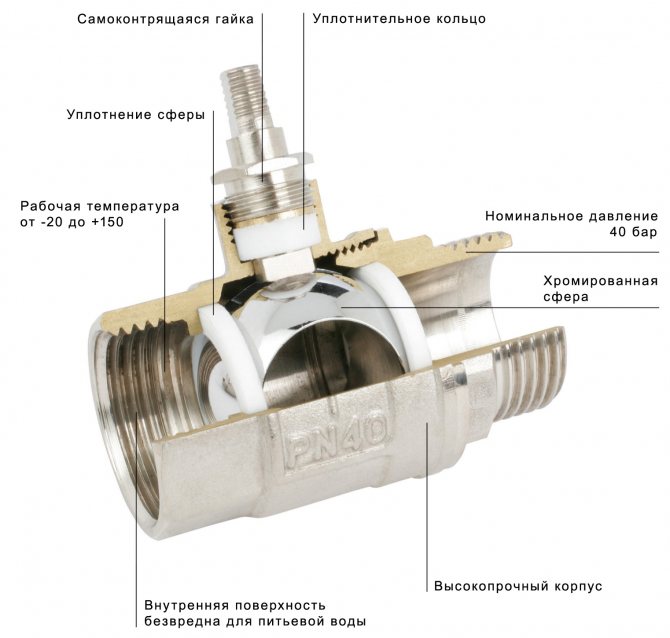

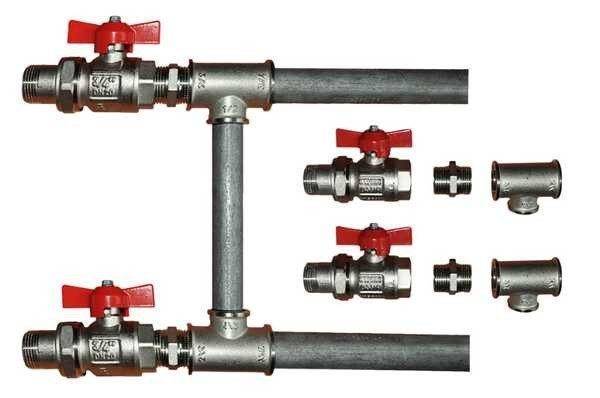

Ball valve body markings

Manufacturers necessarily put a number of designations on the outer sides of the ball valve body (see Fig. 13). All marking symbols must be as clear as possible. Vague and indistinct designations may indicate worn-out forms or that a cheap fake is in front of the buyer.

Fig. 13. Marking on the body of ball valves

The ball valve usually indicates:

The emblem (trade mark, brand) of the manufacturing company is a mandatory attribute of a quality product. DN is the nominal diameter, which can be specified in millimeters (15, 20, 25, 32, 40 and 50 mm), or in inches (for example, ½, ¾, 1, 1 ¼, 1 ½ and 2 ”) PN - working pressure in bar. Depending on the diameter and design features of a particular product, this value can be in the range from 15 to 40 bar. Body material - brass grade according to EN. Date of manufacture of the product - 04/11.

Why do we need locking and regulating devices

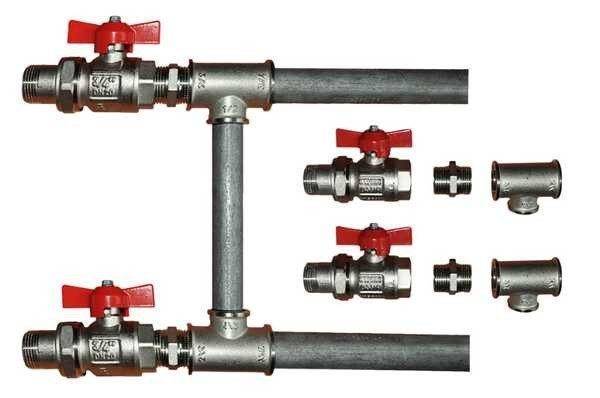

More recently, batteries were connected to the rest of the heating system without any additional elements. Today, the installation of almost every radiator automatically involves the installation of cranes. The reason for these changes is related to the economy and the possibility of unplanned situations.

If the tightness of the radiator is broken, it will leak, it becomes clogged, then you can simply turn the valve, blocking the access of water, and remove the battery for repair or cleaning. To do this, you don't even have to drain the water from the entire system. Such taps are called shut-off valves. They are installed on pipes through which fluid is supplied and removed. In the open mode, they do not impede the free flow of water, and in the closed mode, they completely block its supply.

The valve is necessary to remove the air accumulated in the heating system. Usually it bears the name "Mayevsky".

Some taps allow you to adjust the heating temperature of the heating system. With their help, you can save on heating by lowering the heating temperature of the batteries or turning them off if it is warm outside the window. This is true for both private houses and apartment buildings.

What are the ball valves by body material

3.1. Brass ball valve.

Brass ball valves

The main advantages of brass taps:

- low price; - short delivery times; - good performance for water and gas; - resistance to mechanical stress.

The main disadvantages of brass taps are:

- a small number of diameters, mainly produced from DN 8 to DN 100 mm; - lack of welded execution; - unstable operation at temperatures over 200 degrees C; - impossibility of stable operation on petroleum products.

Steel ball valves

The main advantages of steel cranes:

- low price; - a large selection of models from various manufacturers; - short delivery times; - good performance for hot water and gas; - resistance to mechanical stress; - a wide range of models.

The main disadvantages of steel cranes:

- unstable operation at temperatures less than -40 degrees C; - difficulties during long-term operation in cold water supply systems; - impossibility of operation in slightly aggressive environments.

3.4. Ball valve made of stainless steel (stainless).

The main advantages of stainless steel taps:

- a wide range of working environments; - possibility of operation at temperatures up to -60C.

The main disadvantages of stainless steel taps:

- high price; - narrow model range, mainly produced from DN 8 to DN 300 mm; - long delivery times for most cranes.

Cast iron ball valves

3.6. Ball valve plastic

Ball valves plastic

The main advantages of polypropylene taps:

- durability comparable to brass; - price; - light weight.

The main disadvantages of polypropylene taps:

- Possibility of mounting only on plastic pipes.

Characteristics

When choosing a crane, you should pay attention to its key characteristics. The correct choice will affect the duration of its operation.

Passability

The main elements of a ball valve are a ball and a pipe. In this case, the diameter of the bore of the ball must correspond to the diameter of the pipe. When open, the valve itself is a solid cylinder. If there is no narrowing between the branch pipe and the valve, then such a valve is called full bore. He possesses a number advantages

:

- there is no loss of water pressure head;

- long service life;

According to its characteristics, a full bore ball valve can be considered the best. Despite this, they have disadvantages: significant cost and weight. In order to save money, the passage of the ball valve may be narrower. It is done symmetrically or there is a narrowing on only one side. If the design is asymmetrical, then the narrowing is done in the direction of the water flow. As a result, metal consumption is reduced. Less effort is involved with flow control. But their cross-country ability is already lower.

Thread and pressure

Ball valves are attached to the pipe by screwing onto the thread. It can be in the form of a nut (internal) or in the form of a bolt (external). The latter is correctly called a fitting. The valve is called by the type of thread: "nut-nut" (both threads are internal) or "union-nut" (one thread is external, the second is internal).

The operating pressure of the elements of the plumbing system is measured in atmospheres. One atmosphere - 1 bar. The corresponding designation on the crane is PN. For example, PN20 means a maximum pressure of 20 bar. As a rule, in normal household structures it does not exceed 7 bar in normal use. But always possible overload

, therefore, the locking device must have a safety margin. The minimum PN value for cranes is never lower than 16.

Diameter

The cross-sections of the pipe and the valve do not coincide with millimeter precision. Typically, shop assistants understand what the customer means when they say, "I need a valve for a half-inch male pipe." But in order not to rely on the seller, it is better to know for yourself exactly what pipe sizes and diameters are used in conventional plumbing systems. The diameters of the ball valves are in accordance with certain standards.

The most commonly used pipes at home are ½, ¾, 1 and 1¼ inches. These sizes correspond to 15, 20, 25 and 32 mm, respectively. They are measured by the outer diameter. In order to find out the diameter of the pipe, you can measure it with a caliper or to define

indirectly along the circumference. Divide the circumference by 3.14. But it should be borne in mind: if the pipe is steel, then there may be several layers of paint on it, which leads to a slight thickening. Therefore, such measurements should be brought to the nearest size.

On the valves themselves, they most often write what pipe diameter they are intended for. Full bore valves have one special feature: their threads always match the pipe diameter. This ensures that there are no narrowing of the passage and, as a result, there are no hydraulic losses. For other cranes, depending on the thickness of the pipe, the diameter may differ.

Design differences between tap and valve

The faucet and valve are the parts most often installed on pipe systems. Such a significant demand is due to their reliability and ease of use.However, according to their purpose, the parts have significant differences, which are due to the internal design of each.

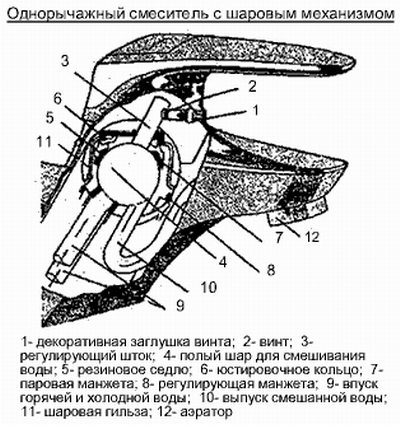

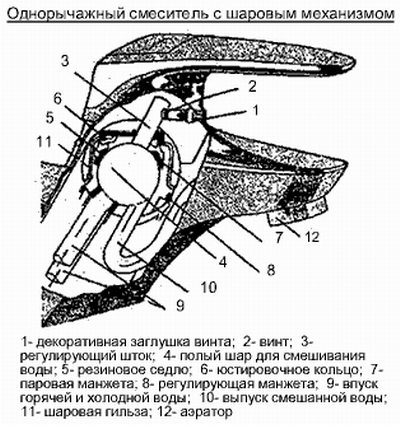

The main nodes of the ball valve

The main structural elements of a ball valve include:

- Housing.

- Rotary knob or gearbox.

- Rod sealing rings.

- Stock.

- A sphere with a through hole through which the tubular substrate flows.

- Saddles that accommodate the main shut-off element.

Main valve assemblies

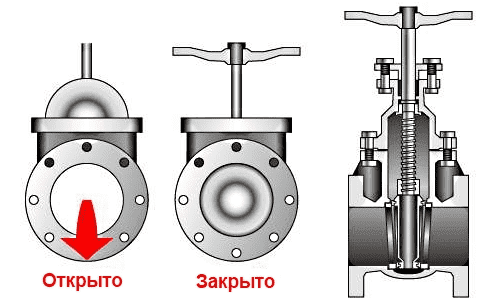

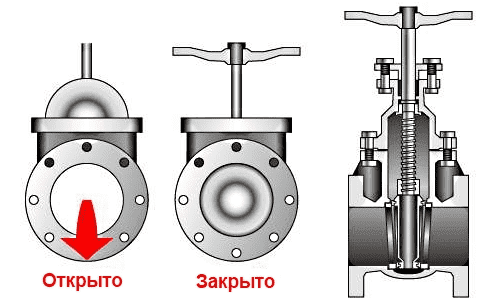

The difference between a tap and a valve can be seen with the naked eye, because the difference in the internal structure has a direct impact on the appearance of the devices. Instead of a ball-shaped locking mechanism, a valve (1) is used here, which is pressed by a stem (2) screwed into the inside of the body (3). Rotation is provided by a handwheel (4). To prevent the penetration of substrates from the pipe, a variety of stem seals (6) and gaskets (7) are used between the cover (8) and the product body.

Application area of ball valves

The scope of application of ball valves is wide enough:

It is formed during the production of beer during fermentation. This is why beer cannot be knocked on. Pressure: The bound carbon dioxide creates pressure that prevents the beer's natural carbon dioxide from escaping by transporting the beer from the barrel to the tap. The working pressure is set at the intermediate pressure regulator.

Pressure reducer: measures a cylinder pressure of approx. 60 bar up to a max. the permitted downward pressure is adjustable. It makes sense to set the operating pressure required for a particular line or type of beer not with a pressure reducer, but with an intermediate pressure regulator.

What are the ball valves by type of control

- these are cranes with a mechanical gearbox installed on them. The reducer must be installed on all valves with diameters over 300mm, as well as on valves with a smaller diameter, where it is necessary to ensure smooth opening of the ball valve.

- these are cranes with electric drives installed on them are used for remote control of technological processes, as well as for emergency shutdown of pipelines.

Ball valve with pneumatic drive

- these are cranes with pneumatic drives installed on them are used for remote control of technological processes, as well as for emergency shutdown of pipelines in hazardous areas, in which the installation of an electric drive is unacceptable.

The principle of operation of the ball valve

Ball valves are designed to completely shut off the working flow and are not applicable to regulate it

.

Replacing the ball valve will not take many years if you use it for its intended purpose and according to the rules set out in the instructions.

Installation: There is a distinction between flat, basket and combination fitting. Accordingly, there are different types of bends. Han: There are different types of faucets. The use of an expansion valve is often recommended. Keg: stainless steel keg, stand permanently installed.

Compensator: The compensator valve has an elongated body, called the so-called. It forms an annular gap in the pipe, the size of which can be adjusted with a small lever. In this way, the valve can be adapted to different dosing rates by varying the volumetric flow.

The principle of operation of a ball valve is based on shutting off the working flow by means of a locking element, which is a ball with a through cylindrical hole.

During the rotation of the ball around its axis, which is perpendicular to the stationary body of the valve, it closes or opens access to the working flow.

With regard to the shape of the hole, it is not always round (rectangular, oval, trapezoidal). The size (diameter) of the opening of the locking element also varies depending on the area of application of the valve and the pipeline network.

Cooling: The supplied drum must be pre-cooled immediately and for a sufficient time to the selected and constantly maintained temperature. Line: Beer lines should be stacked so that they can run empty on their own. They should be kept as short as possible. The beer pipe must be chilled along its entire length.

The quantity depends on the length and cross-section of the pipe. This beer should not be offered to the customer as the quality is no longer the beer in the barrel. O-ring: A seal in the discharge head that separates the beer and gas paths from each other and from the outside world. Damaged O-rings must be replaced as otherwise the instrument will entrap or jeopardize the release of gas into the room.

The ball valve locking element, depending on the purpose and dimensions of the valves, can be sealed mainly in two ways.

Namely:

- ball on supports - for large diameter cranes;

- floating ball - for small cranes.

Valves with additional seal rings are sometimes also available.

Cross-section: beer lines are available with different inner diameters

Important: the nominal diameter must be constant along the entire length of the pipe, since otherwise valve failures occur and mechanical cleaning is impossible. Cleaning: Parts that come into contact alternately with beer and air must be cleaned and disinfected daily with each drum change.

The beer line needs to be chemically cleaned weekly. Even when commissioning an external specialist company, the landlord is responsible for cleaning.

Closing and opening of ball valves is done by turning the handle 90 °.

Features of the

So, recently, special ball valves have been used in gas pipelines. These devices are designed to completely shut off or open the gas flow. The peculiarity of these devices lies in the locking mechanism, which is made in the form of a ball with a through hole. Moreover, the hole in diameter coincides with the diameter of the pipeline (see also the article "Where and how the high-pressure valve is used").

To shut off the flow, the ball is rotated so that the hole is perpendicular to the pipeline, i.e. it needs to be rotated 90 degrees. The locking mechanism is controlled by a lever. The tightness is ensured by rings made of soft and durable materials.

Ball valve with a diameter of 3 - 4 inches

Differences from plumbing fittings

I must say that the external difference between a gas tap and a water tap is that the lever is yellow, not red.

There are much more structural differences:

- They have a more durable body, which is made of special grades of steel or brass with a higher copper content.

- They have a longer connecting thread.

- The locking mechanism is made of extra strong chrome-plated or nickel-plated material.

- The stem is made of durable polymer material.

- These taps are capable of withstanding more pressure than water taps.

- O-rings are more durable and provide better sealing.

Ball valve device

Note! Even though the price of gas taps is higher, they cannot be replaced with plumbing fixtures, as savings can be very expensive. But it is not forbidden to use gas valves instead of plumbing valves.

In general, all that differs a gas faucet from a water stop valve is an increased level of tightness. The rest of the points are not so important in domestic gas pipelines. Therefore, in principle, any valve corresponding to the tightness class "A" can be used for a gas pipeline.

Gas valve in the kitchen

Application features

As a rule, shut-off valves for gas pipelines are installed in the kitchen, i.e. where gas equipment is used. Moreover, a separate valve is installed for each source of consumption.

For example, in houses and apartments where gas stoves and water heaters or boilers are installed, I install separate gas taps for stoves and other devices. In addition, often one common valve is installed at the inlet, which allows you to completely shut off the gas supply.

I must say that stop valves are used not only to shut off the flow, but also to control it, for example, a gas three-way valve allows you to redirect the flow from one pipeline to another. True, such devices are not used in everyday life.

Advice! When implementing gas supply of a house with bottled gas, the general shut-off valves can be omitted, since a valve is always mounted on the cylinder, which allows the gas to be shut off.

Flange faucet

What are the types of ball valves

These are two-way ball valves in which the design of the ball allows you to regulate the flow of the working medium.

Are two-way ball valves with an extended stem designed for installation in underground utilities with the ability to open or close the valve through a carpet installed on the street.

Are ball valves designed for liquid mixing (T-port) or flow distribution (L-port). Such taps are widely used for the installation of manometers and pressure sensors, as well as in complex technological processes.

Are two-way ball valves with the ability to connect a temperature sensor. These ball valves are widely used in the installation of apartment heat meters.

What is better ball valve or gate valve?

An unambiguous answer to the question requires taking into account the current technological need. The gate valves are simple in their design and can be used in various conditions (including rather severe ones). But at the same time, a characteristic feature of their operation is rather intense wear and tear, regular need for repairs, slow shutter release, massiveness.

Ball valves are considered a more versatile and modern option, they are compact, high tightness rates, reliability, control efficiency.

The use of valves remains relevant for the installation of trunk lines and systems with high-speed flow movement. This is facilitated by the low level of hydraulic resistance of the valve. The choice in favor of ball valves (made more often) is associated with ease of installation and maintenance, a high level of tightness of the product and the practicality of its design.

Ball valves - which is better

Ball water taps are used to regulate the temperature of the heating batteries. They can be installed on each battery, on the riser of the entrance to your apartment or anywhere else.

Ball valves for water of various purposes and sizes are produced by the well-known Italian company Bugatti. The list of her products:

- corner taps for water;

- direct taps for cold and / or hot water;

- cranes with "American" (union nut);

- ball valves with an automatic release of air or a small amount of water - drainage machines or Mayevsky taps;

- conventional water taps;

- taps, supplemented with a device for filtering solid particles, etc.

Bugatti cranes are distinguished from most competitors' cranes by their ability to make minor repairs.

Most valves must be disposed of after the start of a leak due to wear of the ball sealing element. Italian valves solve this problem by turning the packing nut. This allows you to get the resource "closed / open" up to 20 thousand cycles.

The Italian company VALTEC has been paying a lot of attention to consumers of its products in Russia and Ukraine for over 10 years.The company's products are designed for rather harsh working conditions in the water supply and heating networks of our countries.

Ball valves of the company have an increased service life.

The controls, reinforced in thickness and working clearance, are supplemented with burn protection in the form of a plastic coating (PVC - polyvinyl chloride) and allow you to turn the crane after the deposition of a large amount of substances harmful to its operation.

The cranes have passed the necessary certification in Ukraine and Russia.

The well-known company FAR from Italy for Russian consumers produces products adapted to the requirements of Russian regulatory documents and harsh working conditions.

One of the products is FAR ball valves. They are:

- with built-in thermometer and / or temperature measurement sensors;

- with an inch thread, red or blue handle, in which a thermometer can be installed;

- with an American union nut and a PRESSFAR press connection, equipped with a handle with the possibility of placing a thermometer in it;

- full bore with metric thread and red butterfly handle, connection with special ends with different pipelines is possible.

One of the oldest Italian companies RMB has been producing fittings and components for water supply and heating for almost 60 years. The company's brochure contains all the necessary equipment for the economical and comfortable operation of heating systems:

- fittings for hot water radiators;

- ball valves with magnetic sludge separators;

- self-cleaning taps with magnetic filters;

- full bore ball valves from 0.5 "to 2";

- standard bore ball valves of different diameters with inch thread;

- check valves for piping systems;

- ball valve with a built-in check valve and many others. dr.

The products of the well-known West German company Honeywell have been produced for many decades. For water supply and heating systems, the company produces, including ball valves for work with automatic control systems.

These devices are an electrically operated shut-off and control mechanism mounted on the ball valve body.

The Honeywell automated ball valve has the following characteristics:

- control as part of the Hometronic Manager system;

- size denomination - 20, 25, 32 mm;

- nominal productivity, cubic meters m / h - 41, 63, 123;

- operating voltage, V - 230, 50 Hz;

- turn time "open / closed", sec - 30.

We hope this information will help you make the right conclusion about which ball valves are better.

Features of valves

Gate valves are distinguished by their structural simplicity, designed to ensure the opening or shutdown of the movement of the substance. The shutter, which is located inside the working cavity of the device body, moves at right angles to the flow axis. The movement of the shutter mechanism occurs due to rotation in the spindle-travel nut assembly. The spindle (stem), passing through the stuffing box seal, serves as a connecting link between the valve and the valve drive, which can be a flywheel, a gearbox, an automatic device.

The fixation of the product on the pipe is carried out in several ways: using flanges, welded or coupling method. The main materials for the production of valves are steel, including stainless steel, and cast iron.

The design specificity of the gate valves does not allow them to be used as control valves. The product shutter can be in two working positions: "open" and "closed". Its installation in an intermediate position leads to a breakdown of the locking mechanism, as a result of which the tightness of the fit of the wedge is disrupted even when it is moved to the extreme position.

Fig. one

Wedge gate valves (the most popular type of valve) are distinguished by impressive dimensions and weight.The use of devices with a rising stem requires additional free space, the presence of which is not always provided by the design of the pipeline.

Varieties

Ball valves are gradually replacing other common types: slide, conical and cylindrical. Their base is a ball, which is used as a shut-off element. During rotation, the contact of the moving element with the coupling seals remains unchanged. Water is passed due to the fact that a hole is drilled inside the ball. Such taps are used in household heating and water supply systems.

There are several species

ball valves:

- welded;

- polypropylene;

- coupling;

- full bore sleeve.

Welded and flanged

Welded valves

fixed by welding, as a result of which it is impossible to dismantle them. Flanged pipes are used in wide diameter pipes. When installing them, additional gaskets are placed to seal the joint. Due to their high tightness and support for high pressure operation, they are used in gas and oil pipelines. They are also widely used in the city water supply system.

Polypropylene

Polypropylene valves are made of polyethylene and polypropylene. They are widely used in aggressive environments, where metal structural elements degrade very quickly. They are subject to deformation from hot water, so they try not to use them in heating systems. In domestic conditions, valves made of polypropylene with a metal shut-off element are still used.

During installation, they are immediately welded to the plastic pipe. It turns out like this hybrid

option: polypropylene, welded. They can already be used in heating systems. Such valves have become widely known relatively recently, thanks to the widespread installation of heating and water supply systems made of polypropylene.

Coupling

Coupling valves are used for narrow

pipes. Their diameter does not exceed 2 inches. Compact, they can be found in a wide variety of water systems. The clutch valve is most common in household structures. To shut off the water flow, simply turn the valve knob. In industrial plants, they are made from steel. For household needs, a more economical material is suitable: brass. Whichever implementation option is chosen, the key

pros

associated with the use of a spherical element remain common to them:

- high reliability;

- ease of use;

- resistance to rust;

- tightness;

- ease of installation.

The full bore version of the coupling valve avoids bottlenecks in the flow of water. Structurally, it is wider and the hole in the ball corresponds to the inner diameter of the pipe. It costs more and weighs more.

Structural valves consist

of the following elements:

The handle is made of nickel. It is carried out both in the form of a butterfly and in the form of a long lever. In the second case, an additional plastic shell is put on the handle. It is especially important on hot water taps: it acts as a heat insulator. The wedge-shaped nut that secures the nipple is made of steel.

The body itself is made of brass. It provides long

service life and is able to withstand the pressure of domestic water supply systems. The brass body, unfortunately, is not always made only from its own alloy. Often there are impurities in cheap specimens, and they can simply crumble over time. The outer part is nickel plated. Therefore, high-quality taps do not always have the yellow color characteristic of brass.

A heat-resistant sealant is used as a seal. teflon

... In the most expensive models, butadiene rubber can also be used as a material. The shut-off ball itself is diamond-ground.The inner part is drilled in the form of a cylinder. It is the wide opening in the cylinder, comparable to the inner diameter of the pipe, that ensures good permeability.

In one of the positions, the ball rotates in such a way that its inner cylinder is located in the direction of the water flow, making up the inner surface of the pipe, which is practically flat without bends. In another, it completely blocks the circulation of water. Insulation is ensured by a high-quality joint between the ground surface and the O-ring.

Choice of gas valves

If a malfunction is found in the gas valve, it is recommended to replace the device as soon as possible. The first step is to select a new valve. When choosing, experts recommend taking into account:

- valve type;

- basic parameters of the device.

The gas pipe valve can be:

- cork. A conical element is placed in the cork valve body, which is driven by a flywheel. There is a hole in the conical element (plug), which, when combined with the hole in the pipe, allows gas to pass to the equipment. The gland acts as a sealing material that seals the connection of the valve with the pipes;

Cutaway plug valve

- spherical. The device of a ball-type gas valve differs from a cork valve in that a ball made of durable metal is located at the base of the locking mechanism. The ball has an opening, which, when the flywheel is turned, is located along the gas pipeline and in this way passes the gas to the consumer.

Gas pipeline valve with ball locking mechanism

According to the method of connection with pipes, a household ball valve can be:

- threaded. The valve is connected to the gas pipeline pipes by a threaded connection;

Threaded valve

- flanged. The connection to the pipes is carried out using flanges, which in turn are fixed with bolts;

Gas valve fixed with flanges

- welded, that is, installed using a welding machine.

Welded gas valve

Threaded and flanged taps are reusable, that is, if necessary, you can remove the device from the gas pipe, check its performance, carry out repairs and reinstall it. The welded valve can only be installed once.

Basic selection parameters

When choosing a gas shut-off valve, it is recommended to pay attention to the following factors:

- diameter of the pipeline. The shut-off element of the valve must completely cover the pipe in the apartment. If the valve is larger or smaller, the tightness of the valve will not be complete;

- thread pitch and diameter on the pipeline. To quickly replace the device, you need a complete match of the specified parameters. Otherwise, you will need to purchase and install additional adapters;

- material from which the gas pipeline valve is made. It is more expedient to purchase brass taps, since they have a longer service life. You can also find silumin, zinc and plastic taps on sale. You can distinguish the material used for the manufacture of the valve by weight. Brass valves are heavier than other materials. In addition, you can inspect the place where the thread is cut. Brass has a yellow tint, and all other materials (except plastic) are gray;

Advantages of ball valves

Ball valves are very compact and at the same time very practical, moreover, attractive from an aesthetic point of view. They are convenient to use, you can instantly block the access to the working flow by slightly turning the handle by 90 °, which is especially important in case of small sudden accidents, like a gas leak or a water pipe leak.

For butterfly valves, the flow is controlled by a disc rotating in the flow path that is located on the center axis.As with ball valves, the positioning time is short as it only takes a quarter turn to fully open and close the valve.

Butterfly valves are simple in design, light in weight and compact in design. Their mounting dimensions are often very short, so they have a significantly lower pressure loss compared to isolation valves. The materials used on the disc and seal may limit their use at higher temperatures and some fluids. Butterfly valves are commonly used for water and air, and in applications with large pipe cross-sections.

Among other things, ball valves are highly wear-resistant and manufactured from non-corrosive materials. They tolerate interaction with aggressive environments well.

In addition, they are quite affordable in comparison with analogues for this purpose. Thanks to all these advantages, ball valves have become the leaders in the shut-off valve market.

Shut-off valves are suitable for a wide range of applications and, depending on the design, can be used for shut-off or regulation purposes. In this type of valve, the capacity is determined not only by the cross-section of the valve seat bore, but mainly by the valve lift. The advantage of check valves over other check valves, which even with a partially open valve, there is less risk of damage to the valve seat and check valve. Among the various types of check valves, especially needle valves are well suited for regulating flow.

Types of ball gas valves

In addition to the fact that the shut-off valves under consideration differ in diameter, the differences lie in the method of installation. Most often, the following types of devices are used in gas pipelines:

| Threaded (coupling) | They have a small diameter. As a rule, these products are used in household gas pipelines. The connection to the pipeline, as it is not difficult to guess from the name, is carried out using a threaded connection. |

| Flanged | They are used in external large-diameter gas pipelines. The connection is made in a flanged way using bolts. Like threaded, these devices are collapsible, i.e. they can be removed and then reinstalled. |

| Welded | Like flanged ones, they are used for external gas pipelines. Their diameter can range from 10 to 70 millimeters. The connection to the pipeline is carried out by welding. Accordingly, this installation option is non-separable. The advantages of such products include complete tightness and high reliability. In addition, the welded shut-off valves are maintenance-free, i.e. tightening of flange connections. |

Advice! In addition to ball valves, there are also plug valves. However, they have less reliability and durability, so they are very rarely used lately.

In the photo - welded shut-off valves

What else is worth paying attention to

- A novelty on the ball valve market is the American ball valve. It allows you to remove the radiator without special equipment and calling the master, for example, during repairs.

- Ball valves for heating systems differ in the type of handles. There are two types: a joystick handle and a butterfly handle. The joystick handles must be installed at a considerable distance from each other, otherwise their use will become a problem due to the massive handle. Butterfly handles are commonly used for small diameter valves.

- Another important component material is clamps - fasteners for heating pipes. Today they are presented in different sizes, depending on the diameter of the pipes. Clamps are made of plastic or metal. Plastic clamps provide pipe mobility, besides, they are relatively cheap (from 4 rubles apiece).Metal clamps provide a stronger connection, but they cost an order of magnitude more (from 15 rubles apiece).

Important

It must be remembered that even the smallest details must be installed by craftsmen with special education and knowledge in this area. Only then will your home be always warm and comfortable.

Our company offers you ball valves from leading manufacturers at affordable prices. The company's specialists will select the ideal components for your heating system.

Dispute on the topic "How to speak correctly: ball valve or ball valve?" will arise more than once, so we will clarify right away: in the singular it is correct to say a ball valve, and in the plural it is a ball valve. However, at the time of this writing, Yandex and Google auto-filling when typing "ball valve" gives the first option "ball valve" - since this option is more often used by technical specialists in "professional jargon" - we personally prefer "ball valve". For simplicity of presentation, we will consider these phrases to be identical (from a technical point of view) and leave this dispute to our favorite teachers of literature and the Russian language. So, in this article we will try to consider in detail all types of ball valves and which ball (ball) valve is best to choose from the whole variety of ball valves.

|

1. What is a ball valve? 2. What are the advantages and disadvantages of ball valves? 3. What are the ball valves according to the body material? 4. What are the ball valves by the type of connection? 5. What are the ball valves according to the type of passage? 6. What types of ball valves are there? 7. What types of sealing ball valves are there? 8. What kinds of ball valves are there? 9. What are the types of ball valves by type of control? 10. What parameters are important when choosing a ball valve? 11. Where to buy a ball valve? 12. What is better to put a ball valve, butterfly valve, valve or gate valve?

Weak sides

Despite the many positive qualities, ball valves have their drawbacks. The water in the water supply system can contain various impurities in the form of scale and rust. If for a long time the valve is fixed in one position, then it begins to clog up with slag. Even saline

deposits. In order to knock off the layers from the ball, it must be turned at least once a quarter.

The quality of the crane is also not always possible to check upon purchase. Some specimens begin to leak over time. As a rule, this is due to a poor-quality oil seal. It can be replaced, but often the locking nut turns with the valve. In addition, the crane can only be operated at positive temperatures. If the water in the faucet freezes, then the faucet itself may simply burst.

Features of replacing the gas valve

Sooner or later, any stop valves may fail, in particular, gas taps are not insured against breakdowns. If this unit is found to be defective, it must be replaced immediately.

It should be said right away that it is forbidden to do this work with your own hands! However, some actions still have to be performed on your own.

After shutting off the gas, you need to light the burner

So, the instructions for replacing this shut-off valve are as follows:

- First of all, you need to report the problem to specialists from the gas service or a private organization that has a license to perform such work.

- Then you need to buy a new crane from a specialist store. It is necessary to first measure the diameter of the pipeline in order not to make a mistake when choosing a product.

- Before the arrival of specialists, a technical passport and a gas supply contract should be prepared. A technical passport is needed to make a note about the work performed.

- Then you need to light the gas on the stove and turn off the central valve.The burner should be left until it has completely extinguished so that all the gas escapes from the pipeline.

- Upon the arrival of specialists, you need to open several windows to create a draft in the room. This is necessary in the event of a gas leak.

- After completing the work, together with specialists, check the installed shut-off valves for leaks.

- At the end of the work, you need to provide the service workers with a technical passport and ask them to make a note there.

Advice! You can use soap suds to detect gas leaks. It must be applied to the joints of the device with the pipeline, as well as to the valve itself. If a soap ball forms in some place, it means that the shut-off valves are allowing gas to pass through.

After completing the work, leave the windows open for another 15-30 minutes, which will ensure complete ventilation of the room.

What are the ball valves by the type of seal

PTFE (fluoroplastic, teflon)

- temperature-resistant polymer, which ensures stable operation on hot and cold water, industrial oils, hydrocarbon mixtures (petroleum products, natural gas), steam (up to 150C). The operating temperature range is from -10C .. + 150C, the maximum allowable temperature is -40C .. + 200C.

Metal to metal

Is a seal in which the valve body and ball are in contact with each other without soft seals. The main advantage of metal seals is resistance to high temperatures. The main disadvantage can be considered the difficulty of ensuring tightness class A.

(no votes yet)