A booster (booster) pump can be a solution to the problem of residents of multi-storey buildings, where water, due to low pressure, does not rise to the upper floors. In such conditions, it is difficult to use the most essential household appliances (washing machines, dishwashers). However, the owner of a private house may also face the problem of low pressure in the water supply system. If the house is connected to the central water supply. And the network of houses connected to the system itself is large. During the active use of water by all consumers, with a large intake of water in the external circuit of the water supply system, the pressure certainly drops, drops below two atmospheres (at such a pressure, the operation of most technical devices using water is impossible).

A booster pump in a private house can also be used as an element of the heating system. Such a device increases the pressure in pipelines with a coolant (in contrast to the often used circulation ones) and is really capable of raising water to a height. That allows you to increase the size of the heating network.

When choosing a pressure boosting pump, there are a few tips to follow

When buying a pump, most users are guided by the size, energy efficiency, power, and price. But with the same power characteristics (even from the same manufacturer), devices may differ in their ability to conduct the required volume of water per unit of time. Moreover, it is impossible to compare mechanisms of different brands in terms of engine power.

The first rule of choosing a booster pump: we select a device according to the characteristics of the operating point (required water flow / pressure).

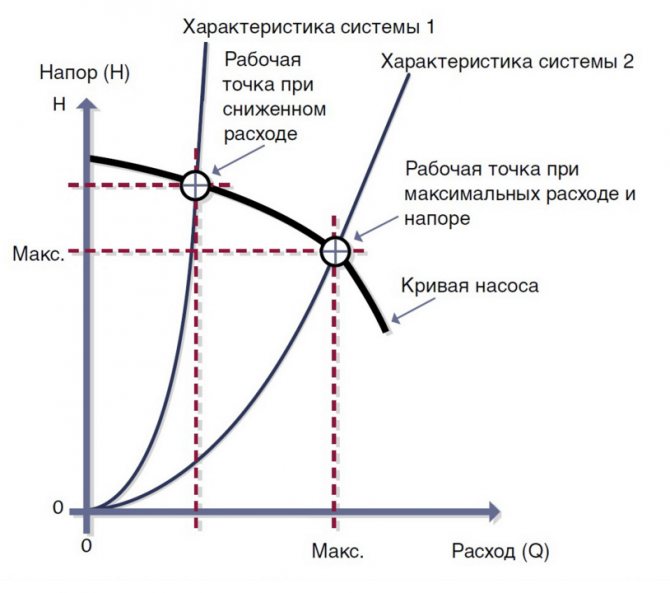

Rule two: before buying a model, you should familiarize yourself with the technical characteristics indicated by the manufacturers. Learn to read pressure diagrams, which must be present in technical manuals. Ideally, the parameters of your operating point should be in the center of such a diagram.

Fig. 1 Example of a diagram with marked operating points

If the operating point in terms of the pressure / flow rate of water is located to the left, it is worth considering buying a smaller pump. Remember that the pump automation turns off the system if there is no water in the water supply. If your pump does not receive enough water, this can lead to permanent failures.

If the operating point on the diagram turned out to be to the left, this model may not suit you either, since it simply cannot provide the passage of the required volume with the required pressure.

To improve the working conditions and the suction of the booster pump, a backwater is organized at the inlet. We turn to the value of NPSH (indicates the required height of the water column) in the passport of the device. The backwater can be created artificially by installing an auxiliary pump. But ideally, you choose a design in which the creation of a backwater is ensured in different modes of water analysis.

Rule three: before going out to buy a pump, find out (measure) the cross-section of your water supply pipes.

Rule four: remember that failure to comply with the technical requirements for operation threatens the buyer with refusals in warranty repair. We read carefully the terms of the guarantee. We meet before the warranty situation and frustrations about wasted funds

Rule five: do not forget that a manufacturer's reputation is a guarantor of high quality. Our store works only with official, reputable equipment manufacturers.All products are certified and supplied with technical manuals.

We understand the reasons for the weak water pressure

The existing regulations state that the pressure in the water supply system should be 4 bar. This is how you can ensure the performance of all household appliances related to water supply. In practice, it is almost impossible to meet such pressure. Since the indicator has errors, both up and down.

Common causes of the problem:

- The reason for the low pressure can be old pipes, which are thoroughly overgrown with limestone, or are covered with rust from the inside. The use of high-pressure water pumps in such cases is impractical - all piping must be replaced.

- Contaminated old filters can also affect the pressure force, changing which easily solves the problem.

- The culprit of a weak water pressure may accidentally become a neighbor from below, who installed a pipeline less than the regulated diameter during repairs.

Sewerage

The domestic sewerage system is designed to drain wastewater from sanitary appliances. Sewer risers (K1) are made of polyethylene pipes PE80 SDR41 in accordance with GOST 18599-2001. To compensate for temperature elongations on plastic risers, expansion pipes are provided every 3 m. Equalizers of electrical potentials from metal baths and shower trays are connected with a copper drive PV 3-1-4 to grounding risers (see EM sheets). Lead the exhaust part of the K1 system 0.1 m above the edge of the ventilation shaft.

The internal drainage network is designed to drain rainwater from the roof of the building into the external stormwater drainage network. To prevent freezing of the funnels and the section of the pipeline laid according to this technical point, their electric heating is provided. The network in the attic is assembled from steel welded pipes in accordance with GOST 10704-91. The riser and outlet are mounted from PE80 SDR17 polyethylene pipes in accordance with GOST 18599-2001. Steel pipes are coated with oil paint for 2 times.

What can be done

If the problem of a weak water pressure is not in the contamination of the pipes, additional equipment will have to be installed to solve it. The installation of a booster pump for a water supply system will be justified with an uninterrupted water supply with a lack of pressure for the operability of household appliances. If the constant voltage does not exceed 1.5 bar., It is recommended to install a boost pump at the inlet of the pipeline to the house. Similar measures can be taken in multi-storey buildings suffering from pressure “deficit”.

If water does not reach your floor at all, the use of high pressure water pumps is not justified. The equipment requires a minimum pressure limit, which is regulated for a specific pump model, to provide the required output value. It is impossible to create pressure from emptiness.

There are several solutions to this problem (however, not every option is easy to implement):

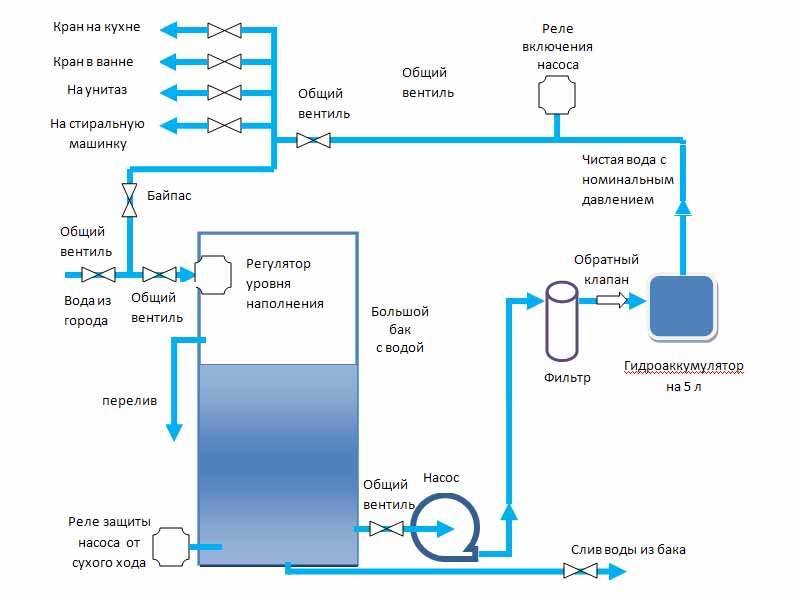

- Installation of a high-pressure pumping station equipped with a large-capacity hydroaccumulator. The main element of the device is a centrifugal pump that can independently raise water to the required height, which allows you to get a good pressure at the outlet. The storage tank included in the package provides a reserve supply of liquid that can be consumed when there is no pressure in the water supply system.

- Installation of a non-pressurized tank filled with water. Usually they are mounted under the ceiling, and a small booster pump is placed directly in front of the water intake point. Its power will be enough for trouble-free water use. The main obstacle to the implementation of the project may be the small size of city apartments.

- Installation of a high-power booster pumping station equipped with a hydraulic accumulator and storage. The presence of a large supply of water will provide residents with the necessary pressure and the proper amount of liquid.

Each of the solutions requires a competent approach and the selection of special equipment.

Pumping station

To ensure the necessary pressure in the network of cold and hot water supply of a residential building, a pumping and booster installation is provided in block A

GRUNDFOS HYDRO MPC-S 3 CR 10-6 Q = 21.66m³ / h, Н = 55m, Рн = 6.25kW (2 working 1 cut). working in intermittent mode in conjunction with 2 membrane tanks "refix D-700".

When the pressure in the hydraulic pneumatic tanks P = 50m - the pumps of the booster installation are automatically switched on, when the pressure in the pneumatic tanks is P = 45m - the pumps are automatically turned off. The pumping station is located in the basement at -3,300. The pressure in the external water supply network is 0.1MPa.

For fire extinguishing, a pumping unit GRUNDFOS HYDRO MХ 1/1 2 CR 10-6Q = 9.5 m³ / h, H = 50.9 m, Pn = 2.25 kW (1 working 1 cut) is provided.

The pumping units are installed on a foundation, on vibration dampers, to absorb noise, the inner room (walls and ceiling) of the pumping station should be sewn up with sound-absorbing material.

Pump selection

The key criteria that need to be clarified before purchasing equipment are performance and pressure rise.

The performance indicator is measured in liters per minute. For the simultaneous operation of 2 taps (for example, in the bathroom and in the kitchen), 10 l / min will be enough. Adding additional water supply points will require 15 l / min.

The magnitude of the pressure rise is measured in bars or atmospheres. 1 bar ~ 1 atm.

Pressure Requirements:

- Washing machine connection - 2 atm.

- Use of a fire extinguishing system - 3 atm.

- Jacuzzi, shower with hydromassage, watering of the area - 4 atm.

The maximum pressure limit for domestic water supply is 7 atm. Exceeding the value can lead to destruction of the water supply system.

Other selection criteria are related to secondary factors: operating conditions, degree of comfort, economic efficiency. These criteria include:

- type - vortex or centrifugal;

- operating mode - manual or automatic.

- liquid temperature - pumps for cold or hot water + universal models;

- casing cooling system - dry or wet rotor.

If, to correct the situation, the installation of a booster pump for water is required, you need to familiarize yourself not only with the selection criteria for the device, but also with the types of pumps.

Pump types

Modern pumps are classified by rotor type: dry or wet.

The first has an asymmetric shape (due to the power unit located to the side). It is equipped with its own cooling system. The design provides for console mounting of the device to the wall. The equipment has decent performance characteristics, it is capable of fully servicing several water intake points at the same time.

The second type of high-pressure water pumps is compact, makes less noise and does not need additional preventive measures. The rubbing elements are lubricated with the pumped liquid. Installation is carried out by direct insertion of the device into the pipe before the water intake or household appliance. The disadvantage of such models is considered to be low performance.

Power selection rules

As already mentioned, in order to avoid malfunctions in the system, it is necessary to correctly determine the optimal power of the installation for increasing the pressure. Comfortable water procedures and starting an automatic machine requires a pressure within 2 atmospheres. When the operation of a jacuzzi, hydromassage and shower cabin is envisaged, the pressure must exceed the specified parameters, and correspond to 5-6 atmospheres.

To determine the existing head, you can use a pressure gauge or an ordinary liter can, measuring the amount of water that poured out of the tap in a minute. Then you should decide on the needs. If, when you open the kitchen tap, it becomes impossible to take a shower, then a booster pump for the water supply system will be enough, which can add a couple of atmospheres.However, when it is envisaged to use a shower stall, washing machine, or other similar equipment at the same time, the consultation of an engineer will be required.

Household water supply

The system of domestic and drinking water supply of cold water is designed to supply water to sanitary appliances, as well as to prepare hot water. The system of household and drinking water supply of cold water is designed for supplying water to sanitary appliances, as well as for preparing hot water. The utility and drinking water supply networks are made: risers and wiring in technical rooms from steel pipes, wiring by floors - polypropylene pipes;

- pipe insulation - "K-Flex". Domestic and drinking water supply pipelines (B1 systems), main pipeline and risers are insulated with 9mm thick K flex-ST flexible tubular insulation.

In the room of the garbage chamber, the installation of a watering valve and a sprinkler is provided. In each apartment, in bathrooms after the water meter, apartment fire hydrants are installed. Water meter in dignity. units of apartments are provided with a radio module. KPK apartment fire hydrant kit (in a case) is designed to equip apartments as a primary fire extinguishing agent. Equipped with a fitting for connection to a water valve with a diameter of 1/2 ", a 15 mm long sleeve with a diameter of 19 mm, a spray gun barrel with an adjustable jet spray, placed in a pouch with a size of 270x270x50mm. To reduce the excess pressure of the water-folding devices located on the 1st floor, the installation of diaphragms with a central hole of ∅7mm is provided.

How does a pump to increase water pressure work?

The water pump for raising the water in the water supply system functions due to the fact that it is equipped with a small electric motor. During operation, pressure builds up in the pipes. The pump is equipped with a robust plastic casing, which is quite compact in size.

When the water flow reaches 1.5 cubic meters, the motion sensor petal changes position. As a result, the pump is automatically turned on. When the water flow stops, the device turns off.

Sometimes it is necessary to use more than one pressure boosting pump, but 2 or more. For example, if the plumbing system in the house was originally designed with defects.

Hot water supply

The hot water supply system is adopted decentralized, i.e. with preparation of hot water in heat exchangers, with circulation through the mains and risers.

The hot water supply system is designed to supply water to sanitary appliances. Hot water supply networks are made: main pipeline and risers of the T3, T4 systems - from polyethylene pipes PE80 SDR17 in accordance with GOST 18599-2001. Hot water pipelines (T3, T4), main pipeline and risers are insulated with 9mm thick K flex-ST flexible tubular insulation.

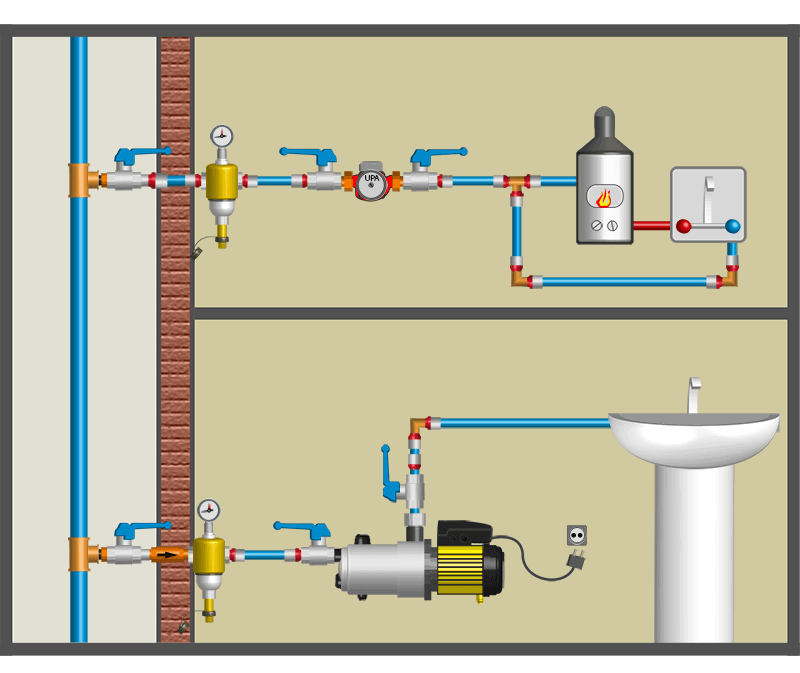

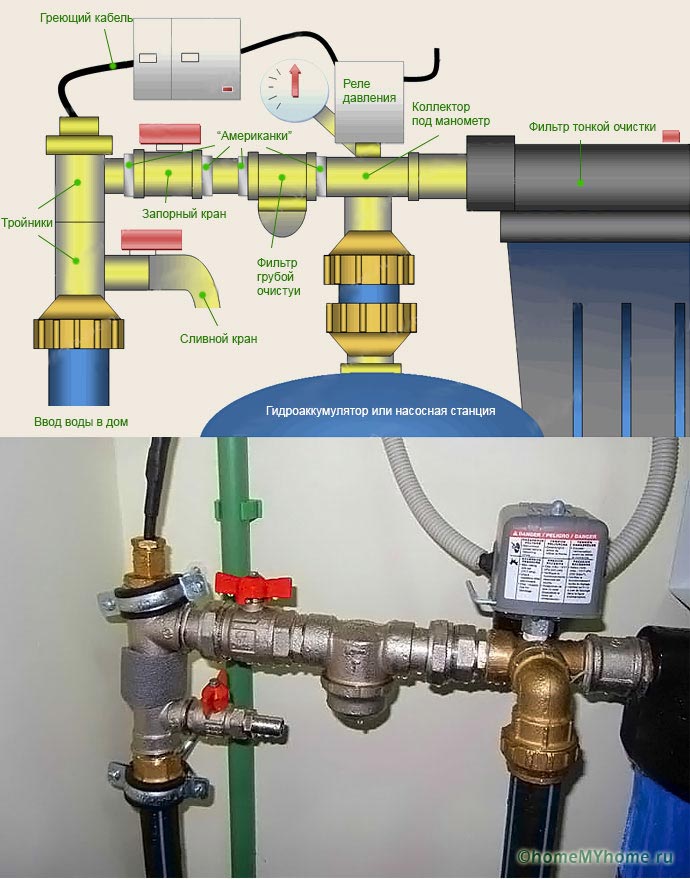

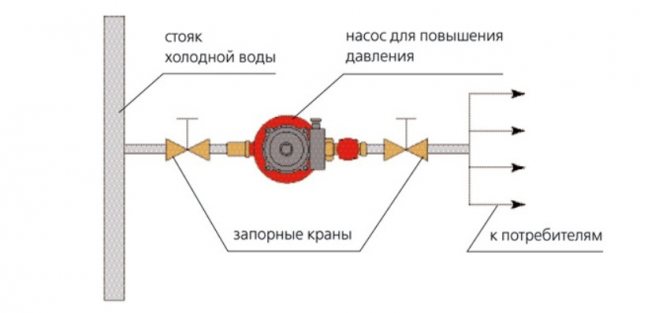

Installation of a pump to increase the pressure in the apartment

Installation of a pressure boosting system is not difficult. You will need to turn off the water supply tap. A pipe is cut out in the area where the device is installed, and a pump is installed in its place, equipped with two outgoing and incoming taps. These elements will ensure that the water is turned off if there is a need for repair or replacement of the pump.

Installation features

When installing, take into account the direction of movement of the liquid, which is indicated by the arrows of the device. In the process of work, technologies are used that are provided for a specific type of pipes and material for the manufacture of a pump for pumping water. Polymer pipes will need to be soldered, metal-plastic pipes are connected with fittings. The integrity of the structure is checked with the motor running. Installation of equipment is carried out taking into account the attached instructions.

Fire-fighting water supply.

In accordance with the requirements of SNiP RK 4.01-41-2006 "Internal water supply and sewerage of buildings", fire hydrants are provided in the building. Water consumption for internal fire extinguishing is one jet with a water consumption q = 2.6 l / s. The ring network of the fire-fighting water supply system is made of steel water and gas pipes in accordance with GOST 3262-75 *. Fire hydrants are installed at a height of h = 1.35 m above the floor of the interroom hall and are placed in cabinets with a hole for ventilation, adapted for sealing and visual inspection without opening. Each fire hydrant has a Start button. PC cabinets are equipped with levers designed to open fire hydrants. To reduce the excess pressure at the fire hydrants located on the 1st, 2nd floors, the installation of diaphragms with a central hole ∅16mm is provided. The fire cabinets provide space for 2 fire extinguishers with a volume of 10 liters.

Mechanism of action

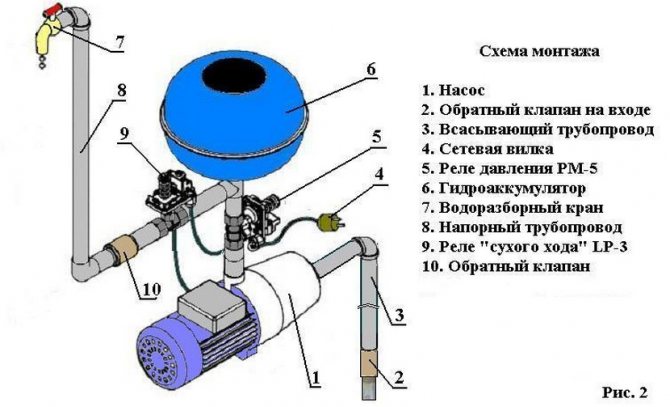

Strapping scheme

The principle of operation depends on the type of installation:

- jet-centrifugal;

- surface centrifugal;

- vortex.

The first type has an ejector inside the body that provides a self-priming effect. Part of the water pumped by the device enters the discharge pipe. The remaining liquid is recirculated using an ejector, which creates a vacuum inside the suction compartment, which leads to an increase in pressure.

Devices of the second type are equipped with a special working chamber required for suction of liquid. It is equipped with a parallel rim impeller. These parts are attached to each other. The water flow falls on the blades, leans back against the walls of the chamber and is collected in the channel. The force of the water flow is converted into head energy, which leads to an increase in pressure.

In vortex installations, an impeller is located on the working shaft, and on it there are radial blades for transferring mechanical energy of the pumped fluid. Thanks to them, the incoming water is recirculated. Multiple blades assist in the transfer of energy, resulting in a gradual increase in fluid flow and keeping it at a high level. Such units are more productive, but noisy, and they require special piping.