Good time of the day, dear reader! The piping systems that supply heat, gas and water to our apartments and houses include many locking and regulating devices, various shaped elements. Limited space in bathrooms and kitchens, interior design features dictate their requirements for the placement of these elements and their number.

In this case, the corner faucet becomes the best option for connecting household plumbing fixtures. It can be immediately installed in the place where the pipes are fed at an angle, without cluttering the structure with additional fittings.

Purpose and scope

Products can be installed as locking devices in any engineering systems, as well as for:

- division into sections of heating risers,

- pump switching - on bypasses;

- convenient dismantling of batteries;

- adjusting the drying temperature of the heated towel rail;

- bleeding air in the heating system (instead of Mayevsky's air taps);

- connections of flexible piping of mixers, washing machines, water heaters, gas stakes and stoves to supply pipelines (gas and water supply);

- connections of supply pipes to air conditioning and ventilation units;

- in places of turning of pipelines for transportation of food solutions, oil products, chemicals.

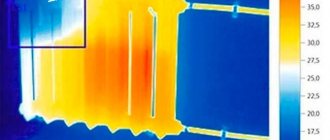

How does a corner faucet for a heating radiator work?

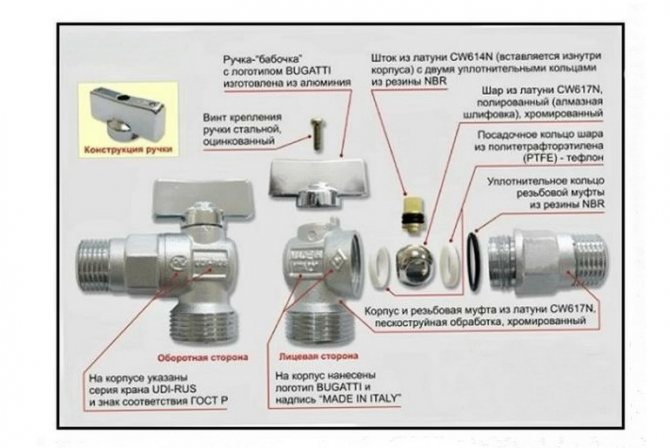

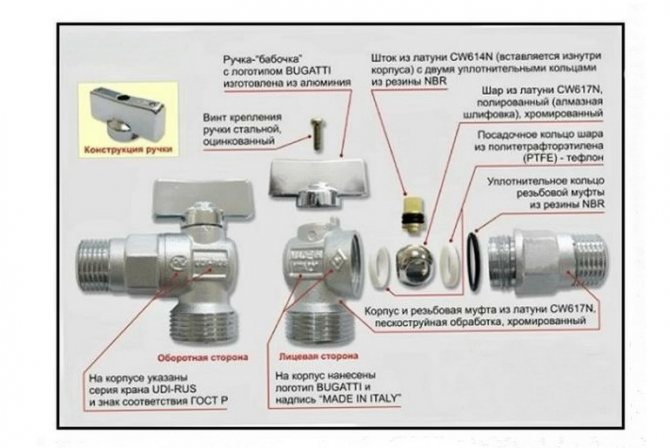

In most cases, ball-type corner valves are used for radiators. Their design includes:

- shutter mechanism;

- body;

- sealing rod;

- washers;

- saddles;

- adjusting knob;

- nuts for fastening and adjustment.

The principle of operation of a ball-type corner valve is to move the shutter, which in certain positions closes or opens the passage for the coolant. The simple design of such a device ensures its reliable operation over a long period of time. The most popular are brass angle faucets for radiators, the prices for which are quite affordable. Standard models are small in size, which makes it possible to install them without restrictions, in almost any heating system. You can find information on the dimensions of such cranes in the next section of the article.

Characteristics

The main technical characteristics are the following product parameters:

- nominal bore diameter - from 15 to 50 mm;

- maximum working pressure - from 10 to 16 atm .;

- type of connection to pipelines - coupling, flanged, welded or combined (one of the nozzles is welded);

- type of thread - internal or external;

- type of control of the locking element - handle - butterfly or lever;

- body parts material;

- operating temperature range - from -20 ° C to 150 ° C (depends on the material used for the manufacture of the device);

- seal tightness class.

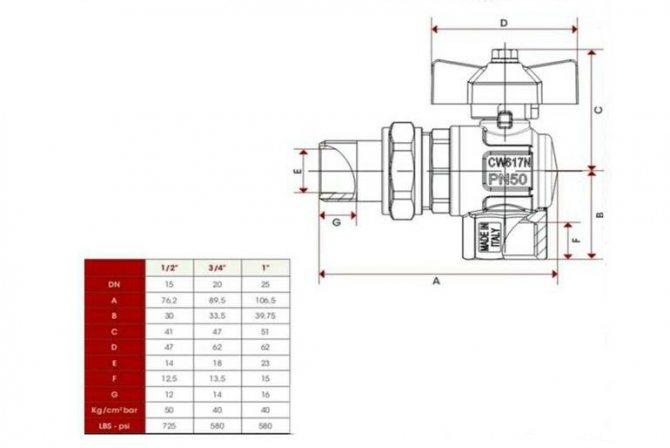

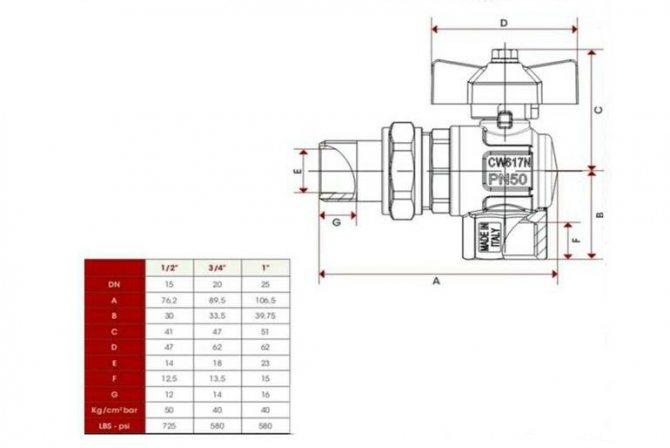

The main dimensions of the products can be determined from the table:

What materials are they made of

A similar product can be made from:

- brass and bronze. They serve for a longer period, as they are almost not subject to scale formation;

- of stainless steel. Despite the high strength and anti-corrosion properties of the material itself, stainless steel faucets quickly become covered with scale, which negatively affects their service life;

- plastic - mainly installed on plastic pipelines. Although plastic is a less strong material than metal, this type of reinforcement is considered to be quite durable;

- silumin (an alloy of aluminum and silicon) are short-lived, quickly wearing out products, mainly made in China.

Advantages and disadvantages

Angular body locking devices have the following advantages:

- reliability and high quality;

- the variety of materials from which they are made;

- ease of use;

- ease of installation;

- low hydraulic resistance;

- affordable price;

- minimum closing time;

- lack of stagnation zones where dirt can accumulate.

If we talk about the disadvantages of these products, then it is one: the impossibility of regulating the water pressure.

Differences between a crane and a gate valve

The main difference between a crane and a gate valve is the principle of their operation. The gate valve can have a gate of different shapes - wedge, disc or sheet, but it always makes perpendicular movements relative to the axis of the fluid flow in the pipeline on which it is installed. To shut off the flow, it is required to rotate the spindle on which the locking part is fixed.

The crane is also included in the group of valves. But, unlike a gate valve, to shut off (or, conversely, start) the flow going through the pipe, it does not require the rotation of the spindle.

The valve gate always has an opening for the passage of the working medium. Accordingly, to start the flow of the medium, you just need to change the position of the shutter element so that the hole in it coincides with the axis of the pipeline. There is no need to rotate the spindle.

Non-specialized information

In addition to the fact that corner taps are shut-off valves, they function as a corner fitting. Those. are used where, due to the zest of the pipeline placement, it is required to rotate at 90 degrees.

It goes without saying that the main purpose of these devices is to shut off the flow of liquid or gas, for example, for the execution of a repair of a plumbing fixture. It is possible to use them to connect any plumbing, be it a mixer or a toilet cistern.

From the outside, the valve looks like an angle fitting with a handle or lever. The latter can have a very different design, for example, the handle of a corner crane of an example of 80 is made in the form of a plastic flywheel, in modern devices, the handle is in the form of a neat switch.

Types and designs

Depending on the design of the closing mechanism, this corner fittings are:

- Ball - with a lock in the form of a ball with a through hole. If the ball in the body cavity turns around with a hole perpendicular to the flow axis, then the flow of the medium stops. The tightness of the product in the closed state is ensured by elastic rings fixed to the saddles and well adhering to the ball. They can have an internal or external thread. The diagram of the device of the Italian-made BUGATTI ball valve can be seen in photo 1.

One of the varieties of angular ball valves is an American crane. They combine a standard ball valve design and a quick coupling type, which is a design of two nipples separated by a single gasket. They use a hexagonal brass union nut to secure the connection.

Crane photo - American

- Conical - with a locking element made in the form of a truncated cone. Such devices operate more smoothly than ball products.

- Valve. The design of this type of valve includes a shutter in the form of an elastic gasket and a worm gear, which presses the stem and the locking element against the seat with a hole. As a result, the gasket will block the passage. By turning the handle, the handwheel can again set in motion the stem, which will raise the shutter and open the bore.The advantage of installing a valve in pipeline systems is its maintainability and the ability to use it not only to block the passage, but also to adjust the pressure. The disadvantages of such products include the rapid wear of the movable pad.

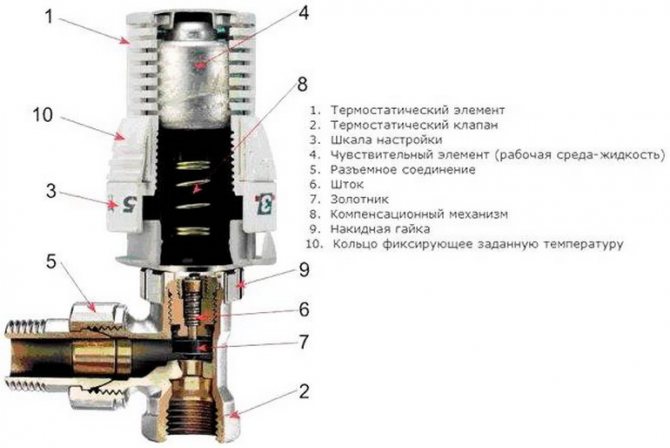

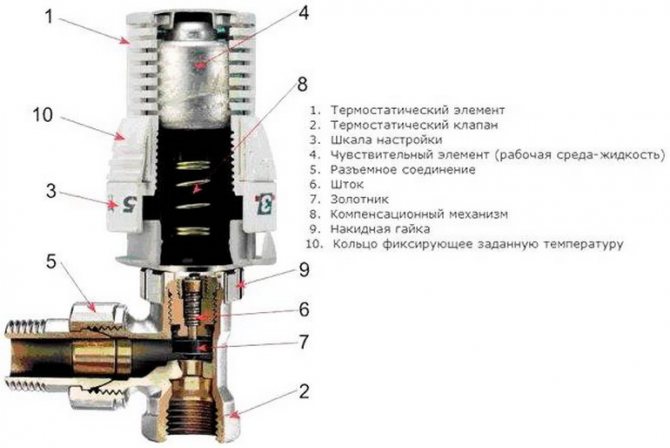

- Radiator. The products are designed for manual adjustment of the flow rate of the coolant entering the radiators. In their group, they are divided into:

- balancing (control) valves. In heating systems, they are usually placed on the return connection to the radiator, on the supply - it is advisable to install a ball valve;

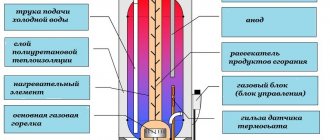

- thermostatic models (with thermal head). The principle of its operation is based on the thermal expansion of media. The main element of the device is a bellows filled with a substance with a high coefficient of expansion in liquid or solid state. The bellows is connected to the valve by means of a stem. When the thermal head is heated, the bellows elongates. It acts through the stem on the valve, which shuts off the flow. When cooled, the siphon shortens and opens the passage opening;

- devices with a thermostat that allows you to control the flow rate of the coolant.

Photo of a thermostatic valve in section:

Main purpose

Products for shutting off the coolant supply are installed in district heating networks, as well as in various types of personal buildings. With their help, it is possible to significantly improve the functionality of a particular heating system.

In most cases, shut-off valves are installed on the inlet and outlet pipelines, which opens up many possibilities.

- If necessary, it is possible to replace the heater without first removing the coolant from the system.

- With the help of a crane, it is possible to control the temperature regime in a specific room, saving energy resources.

- The radiator may also be cleaned without draining the working medium from the heating network.

Note! In most cases, an angle-type ball valve is mounted in front of the heater on the inlet and outlet pipelines of a two-pipe home heating system.

Selection Tips

When choosing a product, you should rely on the following criteria:

- quality characteristics;

- manufacturer's reputation;

- material of manufacture;

- processing technology of constituent parts;

- appearance;

- angle of rotation;

- standard size of pipes;

- price.

Here, it is important not to buy a fake silumin, which outwardly does not differ from a brass product. Its service life is no more than 12 months.

A high-quality brass device can be distinguished by its weight - it is much heavier than a silumin crane.

And yet, do not hesitate to request a quality certificate from the seller confirming the declared technical characteristics of the product.

Selection of corner cranes

What type of tap to install when installing the heating circuit depends on the customer's requirements, on the place where they will be located in the heating circuit, as well as on the purpose of use. The main mistake of buyers who are poorly versed in shut-off and control valves is the purchase of fakes - cheap low-quality products, which are also called silumin. Some dishonest sellers pass them off as brass faucets, even though they are not. Silumin taps usually serve no more than a year, quickly crack under the influence of high temperatures, and even fall off the radiator.

We recommend that you familiarize yourself with: Functional and design differences between a valve and a gate valve

approximate price

The cost of an angle crane, in addition to its standard size, is influenced by the decorative design, the name of the manufacturer and the country of its production.Domestic products are significantly cheaper due to customs duties and delivery distance. Roughly, the price of different cranes with a nominal diameter of 15 mm in Russian retail is:

| Device type | price, rub. |

| Ball (brass) | 260 — 320 |

| Thermostatic tap | 350 — 600 |

| American | 650 |

| Polypropylene product | 130 |

Crane installation and operation rules

No matter how simple the installation process of a corner crane may seem, there are a number of rules that must be followed when carrying out installation work:

- there must be free access to the device;

- the location of the adjusting handle should be such that it does not have obstacles to movement in any of its positions;

- there is usually an arrow on the body indicating the direction of fluid flow; during installation, this kind of indication must be followed;

- in order to avoid leaks in systems that include such a device, it is necessary to properly isolate the junction with the FUM tape;

- at the end of the installation of the product, the system must be checked for leaks.

Required tools and materials

To install the crane, you will need the following tools and consumables:

- scissors for metal or grinder;

- adjustable wrench;

- carving tool;

- calibrator;

- FUM tape to ensure tightness of the joint.

Work progress

The sequence of work on the installation of an angle faucet in the internal water supply network is as follows:

- first, all the liquid from the system is drained. To do this, turn off the water supply using the valve and open the valves;

- in the place where the device will be placed, a section of the pipeline is cut out. Its size should correspond to the length of the valve body;

- threads are cut at the ends of the pipes. If the system is assembled from plastic products, then a calibrator is used to process the ends (deburring, chamfering, leveling the cross-sectional shape);

- winding the sealing tape at least 5 turns. It will protect the threaded connection from deformation and ensure the most tight fit of the bends;

- the product is screwed in and fixed with an adjustable wrench;

- the tightness of the connection is checked. The check is carried out with the water supply turned on. If water oozes at the junction, then it should be additionally compacted with linseed tow or special fillers.

Appointment of corner cranes

The installation of a crane is necessary for solving various tasks:

- cutting off the heat source from the system,

- reducing the level of the coolant flow,

- regulation of heat consumption,

- getting rid of pipeline airing.

The corner faucet makes it possible to turn off the battery for the purpose of repair or flushing, as well as replacing the radiator. In addition, with its help, the level of heat transfer is adjusted in a separate room, for example, in a room where it is necessary to maintain an optimal temperature level.

This is especially important in a private house, where, regardless of the type of heating devices, the first radiators in the system always warm up better than the remote ones. The limitation of heat consumption in the first makes it possible to adjust the heat costs in the entire circuit and save on energy consumption.

Features of operation

The product must operate at a temperature and pressure level corresponding to its technical characteristics. During operation, the joints must be periodically checked, and if the threaded connection is slightly parted, then it must be tightened to avoid leaks. Variants with freezing of liquid in the cavity of its body should be excluded, as this will lead to its damage.

After draining the water from the network, the tap must not be closed immediately. Let it be open for a longer time so that the liquid does not stagnate inside.

Expert advice

- If the design of the system involves placing a crane and a corner next to it, then it is better to replace them with this type of fittings. This solution will save money and simplify the installation process.

- The model should be selected depending on the location of the pipeline. There are products designed for installation only on vertical risers and on horizontal sections.

- It is advisable to add an end valve to the irrigation hose with a device designed to concentrate or diffuse the flow of liquid. The product will work more efficiently.

- Devices with a thermal head should not be covered with furniture or finishing materials and should not be exposed to direct sunlight.

Why do radiators have taps

Each heater is a separate element of the system that needs adjustment and periodic maintenance. If you control the flow rate of the coolant through the batteries, depending on the need for heat, then you can achieve good results in terms of energy savings. That is, radiator valves and taps for heating are designed to solve the following tasks:

- Complete isolation of the heater from the system.

- Limiting the flow of the coolant through the battery.

- Change in the flow rate of the coolant depending on external conditions.

- Bleeding air from the radiator and pipeline network.

There are many situations in which it is difficult to do without disconnecting the battery. For example, a properly working centralized heating system in the middle of spring, when it is already warm outside, but it is simply hot in the apartment. Another case is the need to remove the heater for replacement, flushing or repair. In the absence of shut-off valves, it becomes problematic to carry out any action with the radiator.

Valves are also installed on batteries in a retro style

The limitation of the flowing coolant is carried out in order to balance the individual heating in a private house or apartment. No matter what type of heating system you use, without balancing with valves, the first batteries will always receive more water than the last ones. To limit the flow rate of the coolant at the beginning of the network and thereby equalize all devices with each other is the task of the control radiator fittings.

Automatic control of the flow rate of the incoming heat carrier is a way to save energy used to heat the house. If each tap on the radiator begins to maintain the set air temperature in the room, controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And this is a considerable savings.

Well, the problem of air release when filling the system or during operation is also solved by special air valves installed on all modern radiators. Below is a list of types of shut-off and control valves, listed in the same order as the tasks it solves:

- Semi-turn ball valves in straight and angle design. Made of brass, bronze or polypropylene with a metal insert.

- Radiator balancing valves - straight and angle.

- Control valves with thermal heads (thermostatic valves).

- Air outlet valves - automatic and manual.

For reference. Some do-it-yourselfers use three-way mixing valves to connect heating devices. But such a solution is unreasonably expensive and is rarely used in practice.

Now you should consider in detail which taps are best to put on radiators in different conditions and circumstances. Some options are clearly shown in the video: