Heat-reflecting screen behind the radiator: should we install it or not?

- What is a Heat Reflective Screen

- Where does the heat go

- Polyethylene foam heat-reflecting shield

- Why do you need foil

- Pros of a Heat Reflective Screen

- Disadvantages of a Heat Reflective Screen

- If the radiator is in a niche

- Installation Recommendations

- What not to do

- Installation steps

- Other types of screens

What is a Heat Reflective Screen

In a nutshell: What is a Heat Reflective Screen

The heat shield increases the efficiency of the heating system.

Doesn't require complicated installation and costs a penny.

The structure becomes a barrier between the heat source and the outer wall surface.

The room temperature rises by 2-3 degrees.

At the same time, energy consumption is reduced by 5-7%.

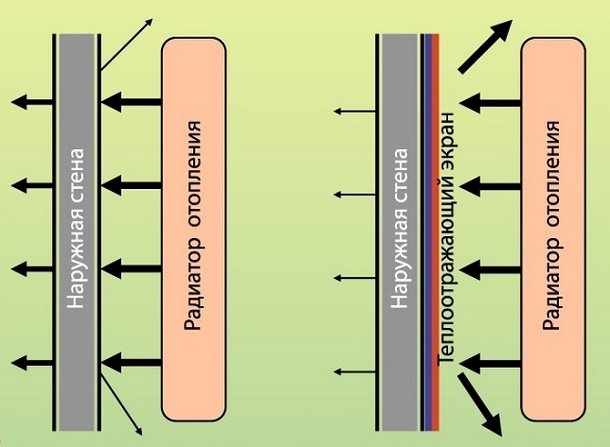

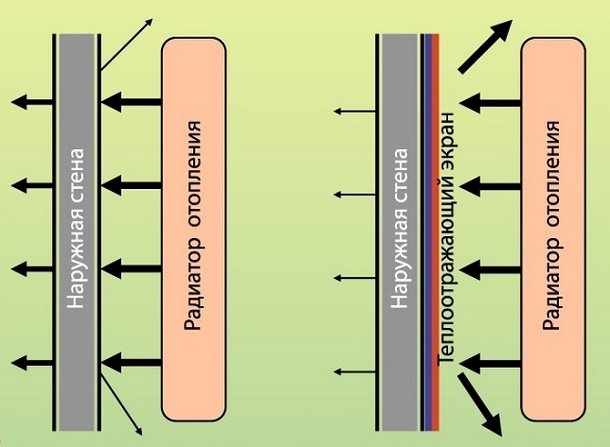

Where does the heat go

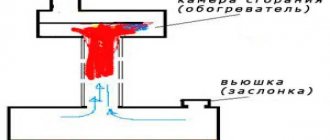

Heating devices in buildings are installed under windows.

The goal is to warm up the air inside and create a heat curtain that prevents the penetration of cold from the street.

Heat spreads from a heated object to a cold one.

The wall temperature is lower than that of the radiator.

In the cold season, the surface behind it heats up to 35-40 ° C.

Instead of heating the air inside a warehouse or office, some of the energy is spent on heating the outer walls.

Polyethylene foam heat-reflecting shield

Substances have different ability to conduct heat.

To prevent energy consumption, the heat-reflecting screen must have a low thermal conductivity - no higher than 0.05 W / (m * K).

Polyethylene foam heat-reflecting shield

Indoors, it is not recommended to use structures made of flammable substances with a loose structure.

For example, mineral wool emitting formaldehyde and microscopic dust is not suitable for the screen.

Although her thermal conductivity coefficient is suitable - 0, 039 W / (m * K).

Heat-reflecting screens made of insulating materials based on polyethylene foam have proven themselves best:

- penofol,

- porilex,

- isolona,

- stisol,

- tepofol.

They are hypoallergenic and safe for human health.

The thermal conductivity of different types of polyethylene foam ranges from 0.029 to 0.032 W / (m * K).

Four millimeters of this barrier will retain the same amount of heat as 10 centimeters of mineral wool.

For insulation between the wall and the heating device, a layer of 3-5 millimeters is enough.

Prerequisite: the heat-insulating screen behind the radiator must be duplicated with aluminum.

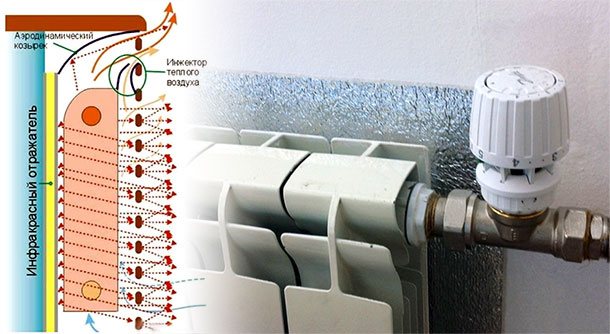

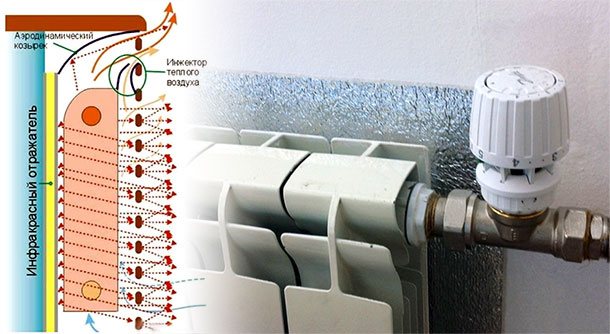

Heat reflector behind the battery

- Effective operation of the heat-reflecting screen behind the radiator can be achieved through the simultaneous adherence to the following rules:

- The screen itself should not obstruct the heat transfer paths from the battery to the room. There are only two such paths. These are streams of warm air going upwards and heat radiation in the infrared range.

- To eliminate the inefficiency of heat transfer in the first case, the ducts must constructively provide unhindered air circulation upward. To do this, they must have the necessary entrances at the bottom. At the same time, the top horizontal should not be solid.

- For the implementation of air flows of warm air, it is worth making heat-reflecting screens with lattice front parts (with the exception of those made of metal).

The heating of the outer wall with a fixed battery becomes much less due to the fact that such screens are mounted between it and the wall.

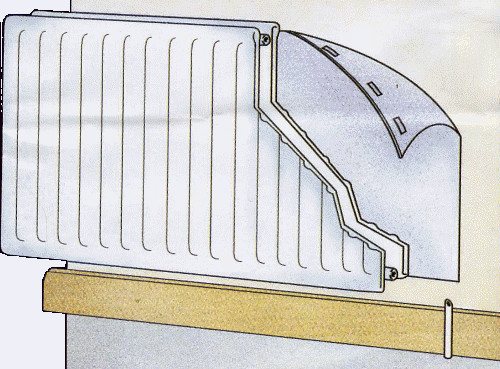

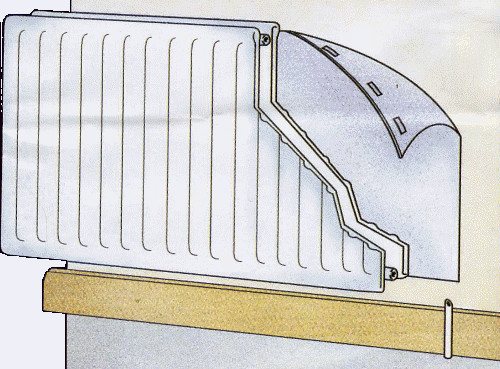

The principle of operation of the heat-reflecting screen behind the radiator

In most apartments and residential buildings, heating radiators are installed under window openings. The section of the wall behind them is always heated the most intensely. Experts say this part can heat up to 35–40 °. Essentially, precious heat is used to heat the outer wall of the building instead of raising the temperature in the room.

The problem of heat loss can be solved in a simple way - install a heat shield on a section of the wall right behind the radiator

Even greater heat losses are observed when the radiator is mounted in a niche. It is thinner than the wall surface. This means that through it, cold air penetrates into the rooms in huge quantities.

Undoubtedly, it is impossible to put up with this state of affairs. And it is not necessary. The problem of heat loss can be solved in a simple and elegant way - install a heat shield on a section of the wall right behind the radiator.

The heat-reflecting device of interest to us not only retains heat. It also protects the batteries from the ingress of dust and moisture particles from behind the wall (through small cracks).

Factory-made heat-reflecting screens are visually appealing. This makes it possible with their help to decorate nondescript sections of the wall behind the heating radiators.

In theory, they can be made from any kind of reflective material by combining it with an insulating product. The main thing here is to withstand one condition. Reflective material must be characterized by a minimum (up to 0.05 W / m * ° C) thermal conductivity.

Foil fully meets this condition. But you cannot use it yourself. The foil, which is a metallized product, will have to be attached to the wall. It will heat up and immediately transfer heat to the wall.

Therefore, it is imperative to make a special layer between the wall surface and the foil. Important! The layer should be thicker than the metallized product.

- Let's consider what materials are used for such screens:

- foil;

- penofol;

- porilex with foil.

It is important! The main thing is that the material from which the reflective screen is made has a low coefficient of thermal conductivity, approximately 0.05 W / m * ° C.

If only foil is used for these purposes, then it should be taken into account that this metal heats up and, if it has contact with the wall, then all the heat will go to it. And to prevent this from happening, it is necessary to make an interlayer between them (foil and wall), which should be thicker than the foil and have a low thermal conductivity.

For this, penofol is used, which is a foamed base or porilex with foil. Moreover, the screen thickness should be 3 - 5 mm.

Also, the heat reflector behind the battery can be made from a roll of foam. It is a 3mm material that is specifically designed to redirect heat to the interior.

Foamed polyethylene is considered the most common and cheapest insulation material. 4 mm of this material replaces a 10 cm layer of mineral wool. The polyethylene is attached to the wall with an insulating layer, and the side with the foil to the heating battery.

- Benefits of a heat-reflecting shield behind the heatsink:

- The heat-reflecting element allows heat to be redirected to the interior of the room, rather than heating the exterior walls. Due to this, you can increase the temperature in the room, while saving on heating.

- Such radiators can be decorative, that is, thanks to this, nondescript places under the batteries are emphasized.

- Radiators do not get clogged with dust due to the suitable cold air from below, they become easy to clean.

- The main advantage is the supply of warm air to the room, as well as the prevention of moisture penetration.

Foil behind the radiator

A heat-reflecting screen with aluminum foil behind the heating radiator completely insulates the walls from heating, which helps to reduce heat losses and increases the efficiency of the heating system by 20%.

A heat-reflecting screen with aluminum foil behind radiators, central heating batteries, completely insulates the walls from heating, which helps to reduce heat losses and increases the efficiency of the heating system by 20%.

At the same time, the room temperature rises by 2-3 ° С. Heat and waterproofing of the roof. It can be used as a heater for underfloor heating only with a polyethylene film (to protect the foil from oxidation in an aggressive environment of cement-sand mortars).

90% of the heat is reflected off the foil, and the thermal insulation layer makes it difficult to lose heat. To achieve the greatest effect and preserve heat, double-sided foiling can be used, that is, the insulating material will be the middle link, and the outer sides of the material are made of foil, but this is unnecessary.

They fix such material with glue, but it will be better if there is a layer of air under such a screen, which will replace the heat insulator. For this, a lattice is used, on which the screen sheet is attached, and the thickness of the recommended layer is 10 mm.

By installing the foil behind the radiator, near the outer wall, you can achieve an increase in the air temperature in the room by 2 degrees.

- The foil is installed according to the following rules:

- The thickness of the insulating layer must be at least 5 mm.

- The reflective side of the screen must face towards the battery.

- If the foil does not have a self-adhesive layer, then it can be attached using the staples of a construction stapler.

In addition to reflecting heat, such a screen can perform a vapor barrier function, that is, protect the wall from moisture penetration into it.

The size of such a reflective screen must be larger than the size of the heating radiator. Of course, you don't need to contact any company to install such a screen for heating radiators, you can do it yourself.

A heat-reflecting screen with aluminum foil behind radiators, central heating batteries, completely insulates the walls from heating, which helps to reduce heat losses and increases the efficiency of the heating system by 20%. The room temperature rises by 2-3 ° C.

Heat and waterproofing of the roof. It can be used as a heater for underfloor heating only with a polyethylene film (to protect the foil from oxidation in an aggressive environment of cement-sand mortars).

Thermal reflective film for batteries

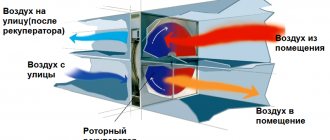

Heat-reflecting film is a roll material on a woven or non-woven base that reflects infrared radiation towards the source.

First of all, you should decide on the place of its application. So, to create a heat-reflecting screen behind the battery, you need to remember that the thermal conductivity of aluminum is very high.

In order not to heat the wall behind the battery, but to reflect the heat into the room, there must be an insulating layer between the film and the wall. The ideal choice in this case is foamed polyethylene films.

Heat-reflecting film Ondutis R Termo is perfect for reducing heating costs. Due to its characteristics, it provides up to 80% heat reflection. As a result, instead of heating the walls, thermal energy is used exclusively for heating the premises.

The low weight of the Ondutis R Termo vapor barrier (70 m2 / g) allows it to be used for insulating light frame structures, and the vapor permeability of up to 10 g / m2 per day provides maximum protection of the insulation from steam even in a Russian bath. At the same time, the film does not lose its properties when the temperature drops from -40 to +120 degrees.

Reflective screen for radiator

Household heating radiators emit a non-directional flow of thermal energy and, simultaneously with heating the air in the room, heat the wall on which they are mounted. By installing a simple heat reflector behind the battery in the battery suspension area, you can significantly reduce heat loss and, with the same energy consumption, raise the room temperature by 2-4 degrees.

The heat reflector screen is ideal for insulating the space behind radiators and radiators, loggias and balconies. This flexible, thin, durable and lightweight aluminum foil-based material has excellent thermal insulation properties.

The principle of operation is very simple - the screen reflects up to 90% of the heat.

You may have noticed that the wall behind the radiator is always warm. This suggests that the heat from the battery simply goes nowhere - to heat the street.

For example, such a simple procedure as warming the area behind the radiator can increase the temperature in the house by 3-6 C, and increase the efficiency of the radiator up to 42%. Consequently, significantly reduce the cost of heating the premises, be it gas and electricity.

In theory, heat shields for radiators can be made by combining any heat-insulating material and reflective foil (for example, expanded polystyrene or mineral wool boards).

But at the moment, the most effective and convenient is polyethylene foam with closed air cells, produced in rolls with one-sided or double-sided aluminum foil coating. The thickness of this material is only 5-10 mm.

Without taking into account the reflective effect, the thermal conductivity of one layer of foamed polyethylene is 0.05 W / m ° C. At the same time, the total heat-reflecting efficiency exceeds foam concrete by 12-20 times, mineral wool and expanded polystyrene by 4-12 times.

- The most famous trade marks in this product category are Penofol, Izospan, Alumofol, Porileks. All of them are available in three versions, distinguished by the foiling method:

- type A: one-sided;

- type B: double-sided;

- type C: single-sided with self-adhesive backing.

What materials are reflectors made of?

In theory, they can be made from any kind of reflective material by combining it with an insulating product. The main thing here is to withstand one condition. Reflective material must be characterized by a minimum (up to 0.05 W / m * ° C) thermal conductivity.

Foil fully meets this condition. But you cannot use it yourself. The foil, which is a metallized product, will have to be attached to the wall. It will heat up and immediately transfer heat to the wall.

Therefore, it is imperative to make a special layer between the wall surface and the foil.

Important! The layer should be thicker than the metallized product.

- Most often, for the manufacture of a heat insulator they use:

- roll foam;

- penofol (foamed polyethylene).

Foam in rolls is a cheap material. Moreover, its heat-shielding potential is 1.5 times higher than that of the well-known insulator - mineral wool. Foamed polyethylene is 2–2.5 times more effective than mineral wool. It has been proven that 4 mm of foam foam provides the same amount of thermal insulation as 10 mm of mineral wool.

You can make your own reflector for the heat coming from the battery. To do this, you need to separately purchase foil and thermal insulation material and fasten them together with tape. But it is easier to purchase a finished heat-reflecting product.

They are produced under well-known brands - Izospan, Porileks, Alumofol, Penofol. It will be easy to choose the right product for the price.

- Heat-reflecting products of different companies differ slightly from each other. Let's consider the possibilities of foil-clad materials using the example of Izospan screens. These products are especially in demand by domestic consumers.The construction market offers several types of Izospan heat-reflecting devices:

- FX. Foamed polyethylene performs the function of a heat insulator, and a lavsan coating plays the role of a reflective film.

- FS. Products with a polypropylene (PP) non-woven base, to which a metallized polypropylene film is attached.

- FD. Analogue of FS model. But the heat insulator is made of PP woven fabric.

Experts recommend using Izospan FX. It has an affordable price, does not contain toxic and harmful compounds, does not deform when heated. However, you can use other varieties of Izospan.

Believe me, the effect of using them will not be worse. Immediately, we note that decent performance characteristics are inherent in heat-reflecting films from other manufacturers. It is not necessary to get hung up on Izospan.

Why do you need foil

Polished aluminum has a higher reflectance of thermal radiation than other metals.

This means that maximum heat will return inside the room.

It is not worth using screens with a double-sided metal backing.

The foil layer on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in building markets deceive buyers by talking about new metallized coatings with fantastic characteristics.

These are fairy tales.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermo-reflecting screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a Heat Reflective Screen

Pros of a Heat Reflective Screen

The heat-reflecting shield behind the heatsink solves two issues:

- increases heat transfer - the main goal,

- reduces heat loss.

All this at minimal cost.

Areas behind the heaters get hotter than others.

As additional insulation, the screen restores their thermal conductivity along with the rest of the wall.

The idea is not new.

It has been tested many times in practice and discussed in specialized literature.

The effectiveness of heat-reflecting screens says

- Umnyakov N.P. - a reference manual "How to make a house warm" and

- German engineer Inrolf Tiator is the author of the Heating Systems manual (original title Heizungsanlagen).

In their opinion, a heat-reflecting screen behind the radiator is able to reduce the heat loss of a 0.51 meter thick brick wall by 35%.

Cons of a Heat Reflective Screen

Disadvantages of a Heat Reflective Screen

The area behind the radiator is no more than 5% of the total area of the outer wall of the room.

The main heat loss occurs through infiltration and windows.

Against this background, the improvement of heat transfer in the area of half a meter is minuscule.

But if you add up the reduction in heat loss in the entire building, the amount of savings will be significant.

For non-insulated walls with low thermal resistance, a heat-reflecting screen is useless.

The heat loss is so large that the improvement of heat transfer on a plot of 0.5 sq. M. will not even be noticeable.

Inspection of the heating system from 15,000 rubles.

Learn more

Content

- Types and applications of heat-reflecting films

- What to Consider When Choosing Heat Reflective Film

- Film Ondutis R Termo - when it is important to keep warm

- How to mount a heat-reflecting film

To provide coolness in summer, the heat-reflecting film on the windows will keep out sunlight in the infrared spectrum, but will not become an obstacle to natural light.

And in order to reduce heat loss in winter, the energy-saving film laid around the entire perimeter of the room will reflect the heat back into the room, preventing the walls and ceiling from heating up aimlessly.

If the radiator is in a niche

In buildings where heating devices are located in niches, heat loss is higher.

The walls behind the radiators are thinner and colder than the others.

Heat is given off not to one, but to three low-temperature surfaces at once.

Therefore, if space permits, it is worth increasing the thickness of the insulating one to 10-15 millimeters.

In addition to the material, it is important how the heat-reflecting screen is attached to the radiator.

Illiterate editing will negate the entire expected effect.

Installation of heat-reflecting screens

Installation Recommendations

The screen is mounted on the wall behind the heater.

The reflective layer unfolds towards the heat source.

It is important not to allow contact between the radiator and the foil, so as not to impede heat transfer.

Russian manufacturers consider a gap of 1-2 centimeters between them sufficient, foreign ones - at least 4-6.

The air gap is part of the thermal insulation barrier.

The thermal conductivity of air depends on temperature and ranges from 0.0259 to 0.0915 W / (m * K).

It makes no sense to put a heat-reflecting screen behind the radiator if it is mounted close to the wall. Squeezed-in insulation will actively collect dust, but will not affect convection in any way.

Ideally, it is necessary to provide for a gap between the wall and the heating system at the design stage.

Then you will have room to maneuver.

Recommendations for the installation of thermal reflective screens

Using reflectors

Heat-reflecting materials can be used for heating pipes

Heat shields can be used for a variety of purposes. The main area of application is internal insulation of premises of different purpose, mainly residential. Thanks to the reflective surface, all the heat from the radiators is directed into the room. This can be done in two ways. The first option is to create two air gaps between the wall and the material, as well as between the insulation and the cladding.

The heat shield can also be used for the roof. It creates thermal and vapor insulation, protecting the roof from moisture.

Reflective surfaces have found their way into pipe insulation and ventilation. In this case, insulation with foil on both sides is used. For pipes with a diameter of less than 159 mm, an air gap is not required, in other cases it is required. A fastener is created from foil film rings at a distance of 300-400 mm from each other, wrapped with insulation on top. It is also possible to lay 10 × 10 mm or 20 × 20 mm wooden blocks along the pipes, and insulation on top. All joints are sealed with aluminum tape.

We offer you to familiarize yourself with Why air appears in the heating system

What not to do

Place the machine too low.

If the distance between the floor and the bottom of the radiator is less than 10 centimeters, the efficiency of heat transfer decreases, and cleaning becomes more difficult.

Do not raise the device too high.

When the gap between the floor and the battery is more than 15 centimeters, the air temperature gradient increases relative to the height of the room, especially in the lower part.

Do not install the device close to a wall.

The distance between the top of the radiator and the window sill is at least 15 centimeters. Less degrades heat flow.

How to mount a heat-reflecting film

Film installation is carried out in stages:

- The roll is rolled horizontally and the vapor barrier is laid with the shiny side out. You need to start laying from the bottom up. The floor is covered first, then the walls and at the very end - the ceiling.

- The film is attached to the wooden frame with a construction stapler, and to concrete or brick walls - with a special double-sided adhesive tape.

- It is important to observe an overlap of 10 cm. The easiest way to fix the joints is to pre-stick the mounting tape close to the edge of the top layer.

- To fix the film around the chimney or other passing holes, the edges are also glued with mounting tape. To provide an ideal vapor barrier in rooms with high humidity, the joints and puncture points of the film are additionally glued with metallized tape.

- To provide a ventilation gap, bars 3-5 cm thick are mounted on top of the film, to which the inner lining is attached.

- When installing a roof in a sauna, in addition to a heat-reflecting film on the inside, an anti-condensation film should be laid on the outside of the insulation.

It is important to remember that there must be a ventilated gap between the foil vapor barrier and the finish. It is thanks to the air gap that thermal energy is transmitted in the form of infrared radiation, which the film reflects. If the interior trim adheres tightly to the metallized layer, instead of reflecting heat, the film will absorb it, neutralizing the entire effect of its use.

4 votes please rate the article:

Installation steps

The most reasonable thing is to provide for the installation of a heat-reflecting screen during the construction phase - after the rough finish, before the installation of heating.

If the repair is complete and the radiator is in place, you will have to remove it.

The size of the screen must correspond to the working surface of the heater.

Then it will be invisible and will not spoil the interior.

In production areas where aesthetics are not important, it is worth increasing the area by 10 percent to ensure maximum reflective effect.

The wall under the window is cleaned of dirt and crumbling plaster, defects are putty, irregularities are removed with sandpaper.

You can start installing.

The heat-reflecting screen behind the radiator is attached with wallpaper glue, "liquid nails" or furniture nails.

If there is enough space, a more reliable option is a lattice base made of thin wooden planks.

Additionally, we get an air layer between the wall and the thermal insulation sheet.

It will have a positive effect on heat transfer.

The radiator returns to its place.

It is important to adjust the position of the device so that a distance of one and a half centimeters (minimum) remains between the foil cover and the back side.

If possible, make the gap larger.

The heat-reflecting screen does not need special care.

Sometimes it is enough to wipe the dust on it.

If the aluminum layer is scratched or torn, metallized tape will help remove the damage.

The functionality will not be affected by this.

Product design

Reflective screen for a metal furnace can be equipped with stainless steel

A reflective screen for a heating battery is made of materials, the main property of which is low thermal conductivity, not exceeding 0.05 W / m * C. All screens have a layer of insulation. The sheet consists of a foil and an interlayer that retains heat.

Foamed polyethylene is often used as insulation. It has good thermal insulation properties, technical characteristics and low cost. Basalt cardboard is mainly used for thermal protection of furnaces.

Frontal reflectors for radiators in saunas are a good replacement for brickwork. They allow you to increase the temperature and heat adjacent rooms. The thickness of the steel sheet must be at least 0.8 m. Silicone paint is used as a coating.

Installing screens under a wooden covering on the wall in the steam room increases the safety of the room. Aluminum foil acts as a screen, the joints between the sheets of which are sealed with special metal tape. It is used if the temperature of the outer walls of the furnace is not higher than 400 ° C.

Special refractory materials to protect buildings from fire

The main advantages of heat reflecting screens:

- Wide range of applications. They are suitable for installation at home, in shopping centers, baths, industries and other residential and non-residential premises.

- Achieving energy savings by keeping the heat in the room.

- Ease of installation. No need to call the wizard to set the screen for the battery

- No specialized care and complex maintenance required.

- Light weight and flexibility.No special conditions are required for transportation.

- A wide selection of materials from any price range.

- Low thermal conductivity.

- Easily cut into pieces of the required size using a regular construction knife.

- Moisture protection.

- The possibility of insulation of internal surfaces.

- Provides a reflection of heat waves with an efficiency of 97%.

We suggest that you familiarize yourself with What is a dew point and how to calculate a dew point in a wall.